High Strength HDPE Uniaxial Rail Track Reinforcement Geogrids

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 15000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

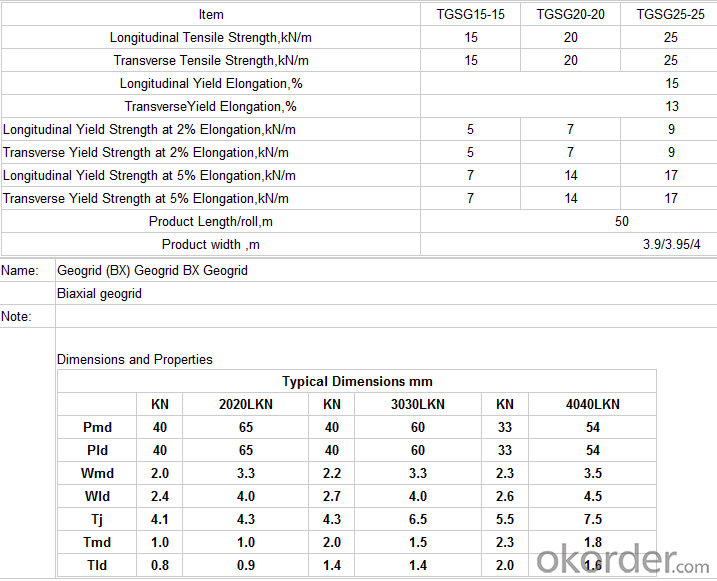

CMAX Uniaxial geogrid are manufactured by a process of extruding, punching, heating and longitudinal stretching. It is made of high density polythylene and they are chemically inert, unaffected by the U.V. rays and fully resistant to aging in the soil environment.

Performance:

High Strength, good flexibility, anti-aging, resisting acid and alkaline.

Applications:

Make reinforcement for various kinds of soft soil foundation enhance and improve bearing ability of the roadbed, make reinforcement for retaining wall, steep slope, dam and bridge abutment under stress status for long term thus to improve quality and prolong service life of the project.

Specification:

Packing:

FAQ

●How long have you been in international trade and geosynthetics industry?

10-year experience in international trade.

20-year experience in geosynthetics field.

●Which payment do you accept?

For you convinience,our payment can be L/C,TT,Westunion,paypal

●Can I know the width you can produce?

Of course we can,our width can be 1 to 6m

●How will you pack the products?

Usually we pack our products by woven bags,also we can do as your requirements

●We want to make sure quality,is free sample available?

We can supply free samples if you need.

- Q: What factors should be considered when selecting a geogrid?

- When selecting a geogrid, several factors should be considered. These include the type and condition of the soil, the desired level of reinforcement, the anticipated loads or stresses, the longevity required, the installation process, and the availability of the geogrid in the required specifications. Additionally, factors such as cost-effectiveness, environmental impact, and compliance with industry standards should also be taken into account when selecting a geogrid. Ultimately, the chosen geogrid should be compatible with the specific project requirements and provide the necessary strength and stability to enhance the performance and longevity of the structure.

- Q: Are geogrids suitable for use in green roof systems?

- Yes, geogrids are suitable for use in green roof systems. Geogrids provide stability and reinforcement to the roof system, preventing soil erosion and promoting the growth of vegetation. They also help distribute the weight evenly, making the green roof more structurally sound.

- Q: Are there any specific maintenance requirements for geogrids?

- Yes, geogrids have specific maintenance requirements. They should be inspected regularly for any signs of damage or deterioration, such as tears, fraying, or disintegration. If any issues are found, appropriate repairs or replacements should be made promptly to ensure the geogrid's effectiveness. Additionally, geogrids should be kept clean and clear of any debris or vegetation that could impact their performance.

- Q: Can geogrids be used in retaining walls for waterfront applications?

- Yes, geogrids can be used in retaining walls for waterfront applications. Geogrids are commonly used in retaining walls to provide stability and reinforcement. In waterfront applications, where there is a higher risk of erosion and soil movement, geogrids can help prevent the retaining wall from shifting or collapsing. They can also enhance the overall durability and strength of the wall, making it suitable for waterfront environments.

- Q: What are the design considerations for geogrids in reinforced soil slopes prone to seismic activity?

- The design considerations for geogrids in reinforced soil slopes prone to seismic activity include selecting the appropriate type and strength of geogrids, considering the geometry and layout of the reinforcement, accounting for the dynamic forces and accelerations during seismic events, ensuring proper connection and anchorage of the geogrids to the soil, and conducting thorough stability analyses to assess the safety and performance of the reinforced slope under seismic loading.

- Q: How do geogrids prevent lateral spreading of soil?

- Geogrids prevent lateral spreading of soil by providing reinforcement and increased stability to the soil structure. When placed within the soil, geogrids distribute the tensile forces and restrict the movement of soil particles, reducing the potential for lateral movement. The interlocking of the geogrids with the soil creates a stronger composite material, preventing the soil from spreading laterally and maintaining its integrity.

- Q: Can geogrids be used in stormwater management applications?

- Yes, geogrids can be used in stormwater management applications. Geogrids are often used to reinforce and stabilize soil in various construction projects, including stormwater management systems. They help to improve the strength and stability of the soil, allowing it to better withstand the forces and pressures exerted by stormwater. Additionally, geogrids can also enhance the performance of stormwater management structures by preventing soil erosion and promoting water infiltration. Overall, geogrids are a valuable tool in stormwater management applications.

- Q: Can geogrids be used in temporary construction projects?

- Yes, geogrids can be used in temporary construction projects. Geogrids are often used as reinforcement materials in soil stabilization and retaining walls, providing strength and stability to the construction site. They can be easily installed and removed, making them suitable for temporary applications.

- Q: The geogrid is convenient for construction, time saving, labor saving, shorten the construction period and reduce maintenance cost.

- That gap has been covered in tape, then tape the knife more she cut off, finally brush mortar.4, let it dry naturally, and then gently polished.

- Q: What is the effect of temperature on geogrid properties?

- The effect of temperature on geogrid properties can vary depending on the type of geogrid and the specific temperature range. In general, higher temperatures can cause geogrids to expand and become more flexible, potentially increasing their tensile strength and allowing them to better distribute loads. However, extreme temperatures can also lead to thermal degradation and reduced performance. It is important to consider the intended application and temperature conditions when selecting geogrids to ensure optimal performance and longevity.

Send your message to us

High Strength HDPE Uniaxial Rail Track Reinforcement Geogrids

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 15000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords