Bitumen Coated Fiberglass Geogrid 100~100/Kn/ For Roadbed Reinforce

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

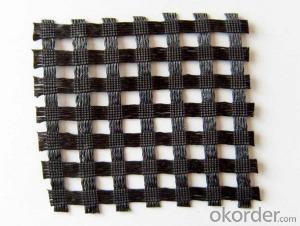

Structure of Bitumen Coated Fiberglass Geogrid:

Bitumen Coated Fiberglass Geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance.

Main Features of Bitumen Coated Fiberglass Geogrid :

fiberglass geogrid for soil reinforcement

- Reinforcement of the surface of road and bridge.

High tensile strength, low elongation

Dyke reinforcement on soft ground for stress evenness,sedimentation adjustment,increase of stability and loading capacity of fundus;

Bitumen Coated Fiberglass Geogrid Images

Bitumen Coated Fiberglass Geogrid Specification

Polyester Geogrid GGF80 Technical Specification | |||

Property | Test Method | Unit | Index |

Wide Width Tensile Strength | |||

MD | KN/M | ≥80 | |

CMD | KN/M | ≥80 | |

Elongation At Break | ≤4 | ||

Grid | MM | 25.4×25.4 | |

Width | M | 1~6 | |

Packaging | Details | ||

Roll Dimensions(W×L) | According to customer requirements | ||

Square Meters Per Roll | |||

Estimated Roll Weight | |||

It is widely used in Asphalt wall, railway foundation, dike slope, runway and sand harnessing.

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q:Who knows how much the staggered distance of the lap joint is

- Specification requires a lot of 0.3M

- Q:How do geogrids help in reducing the risk of landslides?

- Geogrids help in reducing the risk of landslides by providing stability and reinforcement to the soil. They are typically made of high-strength polymers and are installed horizontally or vertically within the soil mass. By interlocking with the soil particles, geogrids improve the overall strength of the soil and enhance its resistance to shear forces. This reinforcement helps to prevent soil movement and sliding, thereby reducing the likelihood of landslides.

- Q:Is there any difference between glass fiber grille and geogrid

- Geogrid also includes polyester grille, steel plastic grille, plastic grille, etc.!

- Q:How do geogrids improve the performance of soil retaining structures?

- Geogrids improve the performance of soil retaining structures by providing reinforcement and stability to the soil. They increase the tensile strength of the soil, preventing it from sliding or collapsing under heavy loads or external forces. Additionally, geogrids enhance the overall durability and longevity of the retaining structures by reducing soil erosion and improving drainage.

- Q:What kind of products are the high strength and high strength micro - pile geocell? Introduce some specific details. Thank you

- At the welding point, there is a unique reinforcing rib combined to produce the effect of micro pile

- Q:The ground treatment is full of geogrid is not along the line direction

- Therefore, the purchase of the appropriate width of the geogrid, laying along the line direction can be, hope to adopt, there is a need for private chat, thank you

- Q:How do geogrids help in reducing maintenance costs?

- Geogrids help in reducing maintenance costs by providing reinforcement to soil structures, such as retaining walls or roadways, which helps them withstand heavy loads and prevent soil erosion. This reduces the need for frequent repairs or replacements, leading to cost savings in the long run. Additionally, geogrids improve the overall stability and longevity of the structure, minimizing the need for ongoing maintenance and maintenance-related expenses.

- Q:Are geogrids suitable for reinforcement of railway ballasts?

- Yes, geogrids are suitable for reinforcement of railway ballasts. Geogrids offer excellent tensile strength and stability, which helps to distribute loads and prevent ballast movement and degradation. They also improve drainage and reduce the risk of track settlement, making them an effective solution for reinforcing railway ballasts.

- Q:What is the geogrid GSJ80/HP

- 4, mixed with asphalt compatible materials - glass fiber geogrid treatment process after coating is designed for asphalt mixture, every fiber is fully coated with high compatibility with asphalt, so as to ensure that the glass fiber geogrid in the asphalt layer and not in isolation of asphalt mixture but, firmly together.5, physical and chemical stability, through special postprocessing agent coating, glass fiber geogrid can resist all kinds of physical and chemical erosion wear, can resist biological erosion and climate change, ensure that its performance is not affected.6, lock and limit the aggregate because of glass fiber geogrid is mesh structure, aggregate in asphalt concrete can be run through them, thus forming a mechanical interlock. This restriction hinders the movement of aggregates, so that the asphalt mixture in the case of load can achieve better compaction state, higher load capacity, better load transfer performance and smaller deformation.

- Q:Are geogrids resistant to chemical degradation?

- Yes, geogrids are typically resistant to chemical degradation. They are designed to withstand exposure to various chemicals commonly found in soil and water, making them durable and suitable for long-term applications in civil engineering and construction projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Bitumen Coated Fiberglass Geogrid 100~100/Kn/ For Roadbed Reinforce

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords