Bitumen Coated Fiberglass Uniaxial and Biaxial Geogrids

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Manufacturer with Bitumen Coated

Description Of Fiberglass Geogrid Manufacturer with Bitumen Coated:

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance.The products after surface covering own the favorable property of alkali resistance and aging resistance. It is used widely to increase the asphalt road surface, concrete road and roadbed (both soft and hard road surfaces). Compared with the traditional road surface, it reduces the cost, prolong the service life, and avoid the reflection road crackle. This product is also used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, etc, and the roadbed.

Main Features of Fiberglass Geogrid Manufacturer with Bitumen Coated:

1.High tensile strength, low elongation.

2.No long-term creep: the product can keep for a long time performance.

3.Thermal stability: fiber glass melting temperature above 1000 ℃.

4.The compatibility with asphalt.

5.Physical and chemical stability.

Specifications of Fiberglass Geogrid Manufacturer with Bitumen Coated:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid Manufacturer with Bitumen Coated:

Strengthen bitumen concrete roadway and reduce and prevent various kinds of reflection gaps on roadway.

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

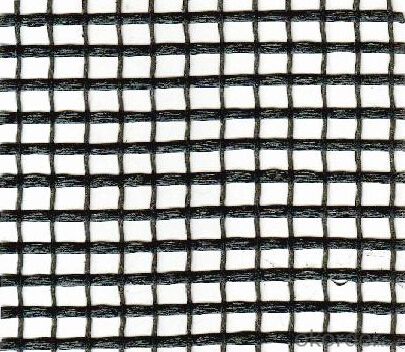

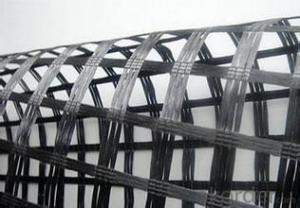

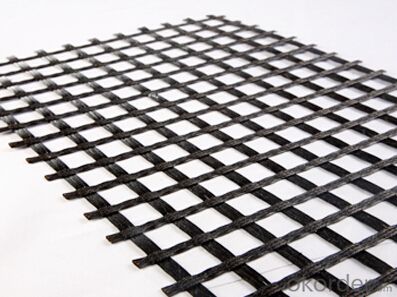

IMages of Fiberglass Geogrid Manufacturer with Bitumen Coated:

FAQ of Fiberglass Geogrid Manufacturer with Bitumen Coated:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: How do geogrids enhance the stability of steep highway embankments?

- Geogrids enhance the stability of steep highway embankments by providing reinforcement and confinement to the soil. These grid-like structures are installed within the embankment, creating a stable platform that distributes the load more evenly. This prevents soil erosion, slope failures, and lateral movement, ultimately increasing the overall stability and safety of the embankment.

- Q: Can geogrids be used in construction of temporary access roads over soft ground?

- Yes, geogrids can be used in the construction of temporary access roads over soft ground. Geogrids are commonly used in civil engineering projects to reinforce and stabilize weak soil. By distributing load and providing tensile strength, geogrids can enhance the stability of temporary access roads, preventing sinking or rutting caused by soft ground conditions.

- Q: How to connect the geogrid with the panel in the reinforced earth retaining wall?

- The geogrid reinforced earth retaining wall can be divided into two parts: one end of the panel reinforcement is fixed, and the other end is provided with tension force until the geogrid is stressed and the earth retaining wall and the reinforced earth retaining wall with no panels are added

- Q: How are geogrids used in civil engineering?

- Geogrids are used in civil engineering to reinforce soil, stabilize slopes, and strengthen the base of roads and retaining walls. They are typically made of high-strength polymer materials and are installed in layers to provide additional structural support and prevent soil erosion. Geogrids help distribute loads, increase soil stability, and enhance the overall durability and performance of civil engineering structures.

- Q: Are geogrids suitable for use in ground reinforcement for wind farms?

- Yes, geogrids are suitable for use in ground reinforcement for wind farms. Geogrids are commonly used in various civil engineering applications, including soil stabilization and reinforcement. They provide tensile strength to the soil, preventing erosion and enhancing the stability of the ground. In the case of wind farms, where the ground needs to support heavy equipment and withstand strong winds, geogrids can effectively reinforce the soil, ensuring the long-term stability and durability of the infrastructure.

- Q: Can geogrids be used in load transfer platforms?

- Yes, geogrids can be used in load transfer platforms. Geogrids are engineered materials that are commonly used in civil engineering applications to reinforce soil, provide stability, and distribute loads. In load transfer platforms, geogrids are employed to enhance the performance of the platform by spreading the load more evenly and reducing the risk of settlement or failure.

- Q: What is the lowest price of two-way Plastic Geogrid

- The cheapest non-standard 15KN the cheapest price of 2.1 this is the factory with the tax price, the general amount of words, you can also be cheaper

- Q: Which instrument is used to measure the permeability of geotextiles?

- Is made of filament or staple through the equipment and technology of different laying into the mesh, after acupuncture process for different fiber intertwined intertwined fixing fabric specification, make the fabric soft, plump, thick, stiff, to achieve different thickness to meet the requirement of use

- Q: What are the factors that affect the design and selection of geogrids for geosynthetic reinforcement of steep slopes?

- There are several factors that affect the design and selection of geogrids for geosynthetic reinforcement of steep slopes. These factors include the slope angle, soil type and properties, anticipated loads and stresses, project objectives, and budget constraints. Additionally, site-specific conditions such as climate, drainage, and vegetation should be considered. Properly considering these factors ensures that the selected geogrids are suitable for the specific slope reinforcement needs, providing stability, erosion control, and long-term durability.

- Q: How do geogrids enhance the performance of geosynthetic clay liner erosion control blankets?

- Geogrids enhance the performance of geosynthetic clay liner erosion control blankets by providing additional reinforcement and stability to the clay liner. They help distribute the loads more evenly, reduce soil movement, and prevent erosion by reinforcing the liner's tensile strength. This enhances the overall effectiveness and longevity of the erosion control system.

Send your message to us

Bitumen Coated Fiberglass Uniaxial and Biaxial Geogrids

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords