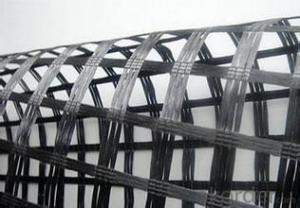

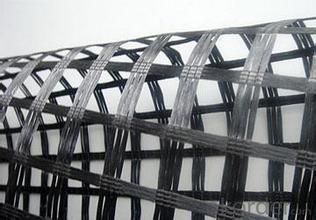

Naue Biaxial Uniaxial Bitumen Coated Black Fiberglass Geogrids

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Description

Fiberglass Geogrid is widely used in civil construction over the whole world. It is manufactured on the basis of high-impact fiberglass.

Fiberglass Geogrid are used as reinforcement materials on mellow soils for railway and car roads, parking places, landing grounds and for the reinforcement of bridge piers, slopes and earth banks, for erosion protection of slopes.

Overall features & benefits

High tensile strength in both the warp and weft directions;

Low elongation;

Good anti-age and alkali-resistance;

Reduce construction cost, extend service life of road and prevent deflection cracks.

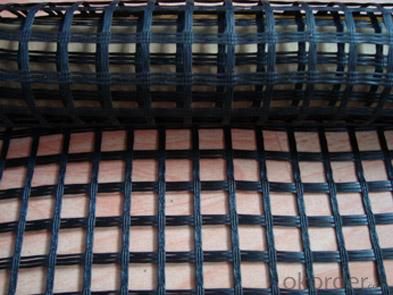

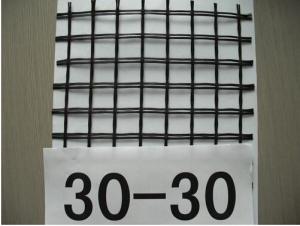

Specification

Intensity: 25, 30,40,50,80,100 KN/M

Width: 1-6M Length: 50-100 M

Application

Reinforcement of highways slopes and higher steepness slopes fixation;

Bed fixation of the various types of road surfacing;

Reinforcement of littoral zone of water reservoirs and Greek beds;

Fixation of the railroad cone slopes;

Support wall construction.

Packaging & Delivery

| Packaging Details: | Rolls |

| Delivery Detail: | 20 Days |

Detiled Data

Tensile | Warp | ≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥120 |

Strength | |||||||

(KN) | Weft | ≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥120 |

Elogation | Fiberglass | <4 % | 4 % | 4 % | 4 % | 4 % | 4 % |

Polyester | <13%< span=""> | 13% | 13% | 13% | 13% | 13% | |

Mesh size(mm) | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | |

25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | ||

42×42 | 42×42 | 42×42 | 42×42 | 42×42 | 42×42 | ||

50×50 | 50×50 | 50×50 | 50×50 | 50×50 | 50×50 | ||

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | |

(Fiberglass) | |||||||

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature | Fiberglass | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 |

Resistant (°C) | Polyester | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 |

Resin | Fiberglass | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 |

Content (%) | polyester | ≤30% | ≤30% | ≤30% | ≤30% | ≤30% | ≤30% |

F&Q

1 How about the delivery time? Lead time since receipt of 30% T/T deposit payment: 3 weeks.2 What kind of payments does jenor support? T/T 3

What's are the MOQ?

We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

4

How to deal with the sample charge?

Accordeing to our company policy, the samples are free, we only charge the freight fee.

And we will return the freight fee If you set the order .

5

Can you produce the product according to customers' requirements ?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

6

Can you tell me your main customers?

That's our customers' privacy, we should protect their information.

At the same time, please rest assured that your information is also safe here.

- Q: The ground treatment is full of geogrid is not along the line direction

- Therefore, the purchase of the appropriate width of the geogrid, laying along the line direction can be, hope to adopt, there is a need for private chat, thank you

- Q: Can geogrids be used in temporary construction access roads?

- Yes, geogrids can be used in temporary construction access roads. Geogrids are commonly used to reinforce and stabilize soil, making them an ideal solution for temporary roads that need to withstand heavy equipment and frequent use during construction projects.

- Q: Geogrid price? Solution!

- 3 for the road surface, so that the grid and pavement materials are mixed together, can effectively disperse the load transfer, to prevent road cracks;4 can withstand a certain impact load;5 can withstand large alternating load;6 shorten the construction cycle;7 in harsh environmental conditions, can also be constructed;8 can prevent frost caused by surface subsidence and crack;9 can reduce the amount of pavement material;

- Q: How do geogrids enhance the stability of railway track embankments?

- Geogrids enhance the stability of railway track embankments by providing reinforcement and preventing soil erosion. These geosynthetic materials are placed within the soil to increase its shear strength, thereby reducing the potential for settlement and slope failure. The geogrids also act as a barrier, preventing the migration of soil particles and maintaining the integrity of the embankment. Overall, geogrids enhance the stability of railway track embankments by improving load distribution, reducing deformation, and ensuring long-term performance.

- Q: What is the tensile strength of a geogrid?

- The tensile strength of a geogrid refers to its ability to resist stretching or breaking under tension or pulling forces. It is typically measured in units of force per unit of cross-sectional area, such as pounds per square inch (psi) or kilonewtons per square meter (kN/m²). The specific tensile strength of a geogrid can vary depending on its material composition, design, and manufacturing process.

- Q: What is the market price of the geotechnical grid in 2017

- (3) geogrid, geogrid laying bottom surface should be smooth, dense, should generally be tiled, straight, no overlap, no curl, kink, two pieces of geogrid adjacent to lap 0.2m, and along the horizontal Subgrade of geogrid overlap every 1 meters with 8 wire were interspersed in the grid connection, and laying on every 1.5-2m U nail is fixed on the ground.

- Q: Can geogrids be used in retaining walls for recreational areas?

- Yes, geogrids can be used in retaining walls for recreational areas. Geogrids provide reinforcement and stability to the soil, increasing the strength of the retaining wall. This allows for the construction of taller, more durable walls that can withstand the lateral pressure exerted by the soil, making them suitable for recreational areas where safety and longevity are important considerations.

- Q: Are geogrids effective in stabilizing riverbanks?

- Yes, geogrids are effective in stabilizing riverbanks. Geogrids provide reinforcement and structural stability to the soil, preventing erosion and maintaining the integrity of the riverbank. They help distribute loads and reduce the potential for slope failures, making them a reliable solution for stabilizing riverbanks.

- Q: Can geogrids be used in coastal protection structures?

- Yes, geogrids can be used in coastal protection structures. Geogrids are often used as reinforcement materials in various coastal protection structures such as revetments, breakwaters, and seawalls. They provide stability to the structure, prevent erosion, and offer long-term durability in challenging coastal environments.

- Q: Can geogrids be used in retaining wall reinforcement systems?

- Yes, geogrids can be used in retaining wall reinforcement systems. Geogrids are commonly used to improve the stability and performance of retaining walls by providing reinforcement and enhancing soil retention. They help to distribute lateral forces and reduce soil movement, thereby increasing the overall strength and durability of the retaining wall.

Send your message to us

Naue Biaxial Uniaxial Bitumen Coated Black Fiberglass Geogrids

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords