Geocells and Geogrids - High Quality Bitumen Coated Black Fiberglass Geogrid (30KN*30KN-200KN*120KN) for Road Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

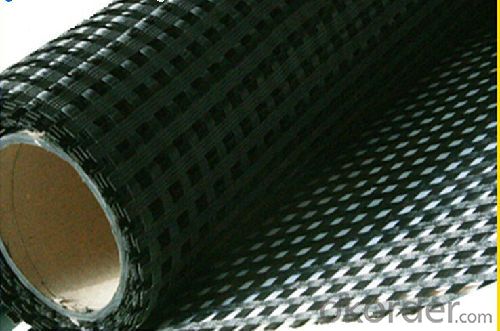

High Quality Bitumen Coated (30KN*30KN-200KN*120KN) Black Fiberglass Geogrid for Road Construction

1.Introduction of High Quality Bitumen Coated (30KN*30KN-200KN*120KN) Black Fiberglass Geogrid for Road Construction

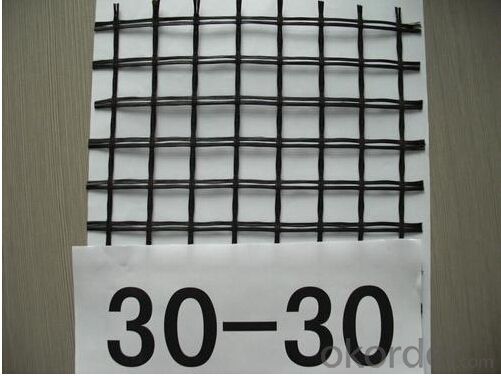

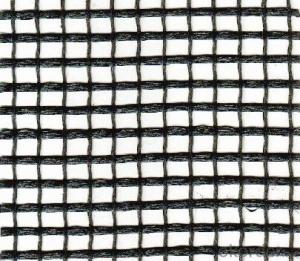

Fiberglass geogrid is a kind of plane network shape material that selects excellent reinforcement non-alkali fiberglass yarn. It is weaven into base material by using foreign advanced warp knitter and adopts warp knitted directional structure. It makes full use of yarn strength in textile, improves its chemical performance and makes it have good tention resistance, tearing resistance and creep resistance and is formed by excellent modified asphalt coating treatment. It follows similar and compatible principle, lays stress on its synthetic performance with asphalt mixture, protects glass fiber base material fully and improve wearing resistance and shearing force resistance of base material so as to make road surface reinforce, to prevent highway harm such as crack and rut from occuring and to solve the problem that asphalt road surface is difficult for reinforcement.

2.Properties of High Quality Bitumen Coated (30KN*30KN-200KN*120KN) Black Fiberglass Geogrid for Road Construction

The product has high intensity, low elongation ratio, thermostable, high module, light weight, good toughness, anticorrosive, long life and so on characteristics.

It can be applied in the old cement road surface, runway’s service, the dike, the river bank, the side protection, project domains and so on road bridge connection surface enhancement processing.

It can reinforce the road surface and prevents the road surface rut fatigue cracking the hot-cold expansion crack and the following reflection crack.

It can scatter the road surface bearing stress, extense road surface service life, the high tensile strength and the low elongation ratio, no long-term slow change. The physical chemistry stability are good anti-weary dehiscence, antilow temperature shrinkage crack and postpone reduction reflection crack.

3.Specification and Technical Data of High Quality Bitumen Coated (30KN*30KN-200KN*120KN) Black Fiberglass Geogrid for Road Construction

The parameters of fiberglass geogrid | |||||||

classification | Model number | Break Intensity (KN/m) | Break elongation ratio (%) | Mesh size (mm×mm) | Breadth (m) | ||

longitudinal | horizontal | longitudinal | horizontal | ||||

Fiberglass geogrid | GG2525 | ≥25 | ≥25 | ≤3 | ≤3 | 12~50 | 1~6 |

GG3030 | ≥30 | ≥30 | ≤3 | ≤3 | 12~50 | 1~6 | |

GG4040 | ≥40 | ≥40 | ≤3 | ≤3 | 12~50 | 1~6 | |

GG5050 | ≥50 | ≥50 | ≤3 | ≤3 | 12~50 | 1~6 | |

GG8080 | ≥80 | ≥80 | ≤3 | ≤3 | 12~50 | 1~6 | |

GG100100 | ≥100 | ≥100 | ≤3 | ≤3 | 12~50 | 1~6 | |

GG120120 | ≥120 | ≥120 | ≤3 | ≤3 | 12~50 | 1~6 | |

Self—adhesive fiberglass geogrid | GGA2525 | ≥25 | ≥25 | ≤3 | ≤3 | 12~50 | 1~6 |

GGA3030 | ≥30 | ≥30 | ≤3 | ≤3 | 12~50 | 1~6 | |

GGA4040 | ≥40 | ≥40 | ≤3 | ≤3 | 12~50 | 1~6 | |

GGA5050 | ≥50 | ≥50 | ≤3 | ≤3 | 12~50 | 1~6 | |

GGA8080 | ≥80 | ≥80 | ≤3 | ≤3 | 12~50 | 1~6 | |

GGA100100 | ≥100 | ≥100 | ≤3 | ≤3 | 12~50 | 1~6 | |

GGA120120 | ≥120 | ≥120 | ≤3 | ≤3 | 12~50 | ||

4.Application and Technical Data of High Quality Bitumen Coated (30KN*30KN-200KN*120KN) Black Fiberglass Geogrid for Road Construction

Reinforcement for road pavement

Reinforcement for railway basement

Reinforcement for tunnel

Reinforcement for slope

Reinforcement for embankment

5.Product Photos and Technical Data of High Quality Bitumen Coated (30KN*30KN-200KN*120KN) Black Fiberglass Geogrid for Road Construction

- Q: How do geogrids improve the stability of slopes?

- Geogrids improve the stability of slopes by providing reinforcement and enhancing the overall strength of the soil. They are typically installed within the slope to distribute stress and prevent soil movement, effectively reducing the risk of slope failure. Additionally, geogrids increase the bearing capacity of the soil, allowing for better load distribution and improved stability of the slope.

- Q: Are geogrids suitable for use in high water table areas?

- Yes, geogrids are suitable for use in high water table areas. Geogrids are commonly used in construction and civil engineering projects to provide soil stabilization and reinforcement. They are designed to withstand high water table conditions, making them an effective solution in such areas. Geogrids can help distribute loads, increase soil strength, and prevent soil erosion, making them a reliable choice for projects in high water table areas.

- Q: Can geogrids be used in mining tailings management applications?

- Yes, geogrids can be used in mining tailings management applications. Geogrids are often employed to reinforce and stabilize tailings dams, prevent soil erosion, and improve the overall stability of the tailings impoundment. They can also assist in controlling the settlement and deformation of the tailings, providing a reliable and effective solution for tailings management in the mining industry.

- Q: How much is the horizontal overlap length of the steel plastic geogrid

- It should be 20cm to 40cm, it's a little longer

- Q: What is the typical weight of a geogrid roll?

- The typical weight of a geogrid roll can vary depending on the specific type and size of the geogrid. However, geogrid rolls generally range in weight from 50 to 500 pounds.

- Q: Can geogrids be used in pipeline trench stabilization applications?

- Yes, geogrids can be used in pipeline trench stabilization applications. Geogrids are commonly used in civil engineering and construction projects to reinforce soil and provide stability. They can be used in pipeline trench stabilization to prevent soil erosion, improve load distribution, and enhance the overall strength and performance of the pipeline system.

- Q: Geogrid is mainly used for what?

- Bi directional plastic geogrid is suitable for various highway and railway subgrade reinforcement. Increase the bearing capacity of the roadbed, prolong the service life of the roadbed; prevent the cracks on the road surface, reduce the maintenance cost and shorten the construction period.Bi directional geogrid is suitable for large parking lot and wharf freight yard, etc.. The bearing capacity of the foundation is increased and the ground is prevented from collapsing. The utility model has the advantages of beautiful and neat appearance, convenient construction, time saving and labor saving.Bidirectional geogrid is applied to the two reinforcement of the soil slope reinforced by unidirectional plastic geogrid.1, to further enhance the slope, to prevent soil erosion, convenient transportation;2, the use of vegetation growth, beautify the environment, reduce pollution.Bidirectional geogrid is suitable for railway and highway slope protection.1, to prevent rock slides, causing harm to people or vehicles;2, to maintain the railway, highway unblocked.Bidirectional geogrid is suitable for highway, railway and culvert.1, to prevent cracks in culvert, reduce maintenance costs;2, reduce the thickness of the surface, save costs; played a filter - protection.

- Q: Can geogrids be used in retaining wall construction?

- Yes, geogrids can be used in retaining wall construction. Geogrids are commonly used as a reinforcement material in retaining walls to enhance stability, prevent soil erosion, and increase load-bearing capacity. They are typically installed horizontally within the soil layers of the retaining wall structure to distribute the forces exerted by the retained soil.

- Q: Can geogrids be used in temporary construction projects?

- Yes, geogrids can be used in temporary construction projects. Geogrids are commonly used to reinforce and stabilize soil in various construction applications, including temporary structures such as access roads, parking lots, and foundations. They provide strength and stability to the soil, preventing erosion and maintaining the integrity of the temporary construction project.

- Q: Can geogrids be used in ground reinforcement for sports fields?

- Yes, geogrids can be used in ground reinforcement for sports fields. Geogrids are commonly used to stabilize and reinforce soil in various applications, including sports fields. They can help improve the load-bearing capacity, reduce soil movement, and increase the longevity and durability of the playing surface.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Geocells and Geogrids - High Quality Bitumen Coated Black Fiberglass Geogrid (30KN*30KN-200KN*120KN) for Road Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords