Geogrids for Velocity Slopes - Fiberglass Geogrid 120KN for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid 120KN for Road Construction

Description Of Fiberglass Geogrid 120KN for Road Construction:

1. A kind of planar mesh material using alkali-free fiberglass yarn as base body and

then coated with high quality modified asphalt.

2. Warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant.

3. Coated with asphalt making full protection of the fiberglass matrix and greatly

improving its wear and shear resistance.

4. Having a good performance in pavement strengthening, track cracking and solving

difficulties of strengthening the bituminous pavement.

Main Features of Fiberglass Geogrid 120KN for Road Construction:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications of Fiberglass Geogrid 120KN for Road Construction:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid 120KN for Road Construction:

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

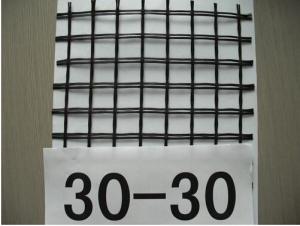

IMages of Fiberglass Geogrid 120KN for Road Construction:

FAQ of Fiberglass Geogrid 120KN for Road Construction:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: The tensile strength of a steel bar is about the number of cattle per square millimeter per square millimeter. The tensile strength of Gsa's cattle per meter, understand the carrying capacity of tensile Gsa every one meter in width is the number of cattle (considering Gsa gap), or single Gsa every one meter in length tensile capacity is the number of cattle (the size effect of Gsa does not consider the length direction). Please advise!

- Plastic mesh grille in custom-made case, first calculate the root number and the wire is thick, in the calculation of mesh size for tensile impact, your problem is that the tensile strength of steel grating is the tensile strength of each of the above. There are problems can be private chat, hope to adopt Thank you

- Q: Can geogrids be used in erosion control blankets?

- Yes, geogrids can be used in erosion control blankets. Geogrids provide additional strength and stability to erosion control blankets, helping to prevent soil erosion and promote vegetation growth in areas prone to erosion.

- Q: What are the advantages of using geogrids over traditional reinforcement methods?

- Geogrids offer several advantages over traditional reinforcement methods. Firstly, geogrids are lightweight and easy to handle, making installation quicker and more efficient. Secondly, they provide a higher tensile strength and better load distribution, resulting in improved stability and reduced deformation of the soil. Additionally, geogrids are resistant to chemical and biological degradation, ensuring their long-term performance. They are also cost-effective as they require less material and labor compared to traditional methods. Lastly, geogrids are versatile and can be used in various applications such as retaining walls, slopes, and roadways, offering a flexible solution for different engineering needs.

- Q: Unidirectional tensile plastic geogrid manufacturers which good

- As the polymer in the manufacture of plastic polymer in the process of heating with the extension of the process of re orientation, strengthen the link between the molecular chain force, to achieve the purpose of improving its strength. Its elongation rate is only 10% ~ ~ of the original plate of 15%

- Q: What are the factors that affect the cost-effectiveness of geogrid-reinforced structures?

- There are several factors that can affect the cost-effectiveness of geogrid-reinforced structures. These include the type and quality of geogrid material used, the design and engineering of the structure, the site conditions and soil properties, the construction methods employed, and the maintenance and lifespan of the structure. Additionally, factors such as material availability and transportation costs, labor expenses, and any required permits or regulatory compliance can also impact the overall cost-effectiveness of geogrid-reinforced structures.

- Q: Are geogrids suitable for use in slope reinforcement during excavation?

- Yes, geogrids are suitable for use in slope reinforcement during excavation. Geogrids provide stability and reinforcement to slopes by distributing the load and preventing soil erosion. They are effective in strengthening the slope, reducing the risk of landslides, and improving overall safety during excavation operations.

- Q: Can geogrids be used in reinforcement of underground storage tanks?

- Yes, geogrids can be used in the reinforcement of underground storage tanks. Geogrids provide additional stability and strength to the tank's structure, preventing soil and groundwater pressures from causing deformation or collapse. By reinforcing the surrounding soil, geogrids ensure the tank's integrity and longevity.

- Q: Can geogrids be used in landfills?

- Yes, geogrids can be used in landfills. Geogrids are commonly used in landfill applications to reinforce slopes, stabilize soil, and improve overall stability and performance of the landfill structure.

- Q: Are geogrids resistant to chemical degradation?

- Yes, geogrids are generally resistant to chemical degradation. They are designed to withstand exposure to various chemicals commonly found in soil and water, such as acids, alkalis, and organic compounds. This chemical resistance ensures the long-term durability and performance of geogrids in different environmental conditions.

- Q: What are the long-term performance characteristics of geogrids?

- The long-term performance characteristics of geogrids include excellent resistance to chemical and biological degradation, high tensile strength, stability, and durability. Geogrids are designed to provide long-lasting reinforcement to soil structures, retaining walls, and roadways, maintaining their effectiveness and integrity over many years of use.

Send your message to us

Geogrids for Velocity Slopes - Fiberglass Geogrid 120KN for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords