Self-Adhesive Bitumen Coated Fiberglass Geogrid Geocells for Driveways

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

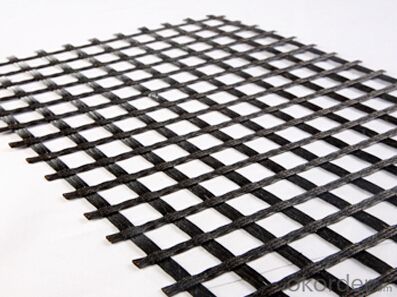

Fiberglass Geogrid with Self-adhesive Bitumen Coated

Description Of Fiberglass Geogrid with Self-adhesive Bitumen Coated:

1. A kind of planar mesh material using alkali-free fiberglass yarn as base body and

then coated with high quality modified asphalt.

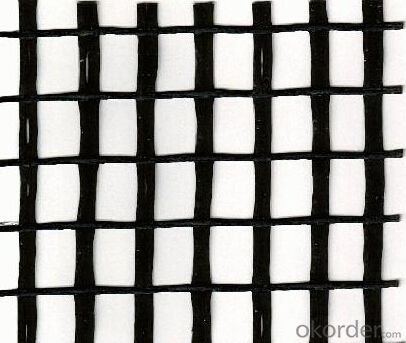

2. Warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant.

3. Coated with asphalt making full protection of the fiberglass matrix and greatly

improving its wear and shear resistance.

4. Having a good performance in pavement strengthening, track cracking and solving

difficulties of strengthening the bituminous pavement.

Main Features of Fiberglass Geogrid with Self-adhesive Bitumen Coated:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications of Fiberglass Geogrid with Self-adhesive Bitumen Coated:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

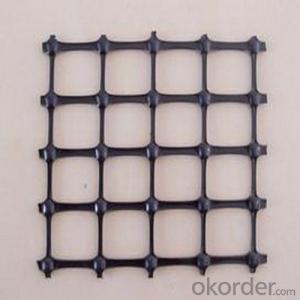

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid with Self-adhesive Bitumen Coated:

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

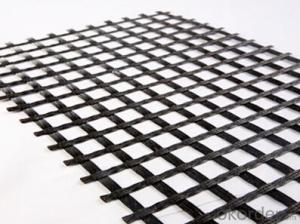

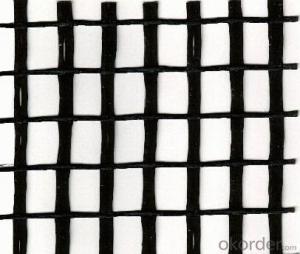

IMages of Fiberglass Geogrid with Self-adhesive Bitumen Coated:

FAQ of Fiberglass Geogrid with Self-adhesive Bitumen Coated:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: How do geogrids improve the performance of reinforced soil foundations?

- Geogrids improve the performance of reinforced soil foundations by providing additional tensile strength and stability to the soil. They act as a reinforcement material, dispersing the applied load more evenly and reducing the potential for settlement or lateral movement. Geogrids also help to increase the bearing capacity of the soil, preventing excessive deformation and enhancing the overall durability and longevity of the foundation.

- Q: Manufacturers to quote the price.

- Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid.

- Q: Are geogrids suitable for use in soil reinforcement for coastal protection structures?

- Yes, geogrids are suitable for use in soil reinforcement for coastal protection structures. Geogrids are commonly used in such applications as they provide excellent reinforcement to the soil, improving its stability and resistance against erosion caused by waves and tides. They offer high tensile strength, durability, and resistance to harsh environmental conditions. Additionally, geogrids can be easily installed and integrated into various coastal protection systems, making them an effective solution for reinforcing soil in coastal areas.

- Q: How do geogrids help in reducing the risk of soil liquefaction?

- Geogrids help in reducing the risk of soil liquefaction by reinforcing the soil and improving its stability. They provide additional strength and prevent the soil from losing its strength and becoming liquefied during earthquakes or other dynamic loading events.

- Q: Are geogrids effective in preventing soil erosion on hillsides?

- Yes, geogrids are effective in preventing soil erosion on hillsides. Geogrids are typically made from durable materials that reinforce the soil, providing stability and preventing it from being washed away by water or eroded by wind. By distributing the forces exerted on the soil, geogrids help to maintain its integrity and prevent erosion, making them a reliable solution for protecting hillsides against soil erosion.

- Q: What is the use of glass fiber grille paving asphalt road

- Fiberglass geogrid is glass fiber as the material, the reticular structure material of the knitting process, for the protection of glass fiber, improve the overall performance of geo composites through a special coating treatment process and the. The main component of glass fiber

- Q: How do geogrids enhance the performance of geosynthetic clay liner capillary barriers?

- Geogrids enhance the performance of geosynthetic clay liner capillary barriers by providing additional reinforcement and stability to the liner. They help distribute loads more evenly, increase tensile strength, and reduce the potential for deformation or failure of the liner system. Additionally, geogrids assist in controlling lateral movement and prevent the loss of clay particles, ensuring better long-term performance and effectiveness of the capillary barrier.

- Q: Do geogrids affect groundwater flow?

- Yes, geogrids can affect groundwater flow. Geogrids are commonly used in civil engineering projects for soil stabilization and reinforcement. They can create a barrier that restricts the movement of water, altering the natural flow of groundwater. However, the extent of the impact on groundwater flow depends on various factors such as the design, installation, and permeability of the geogrids.

- Q: What are the quality control measures for geogrid manufacturing?

- Quality control measures for geogrid manufacturing include: 1. Raw material testing: Ensuring that the materials used in the manufacturing process meet the required specifications and quality standards. 2. Process control: Implementing strict monitoring and control of each stage of the manufacturing process to ensure consistency and adherence to quality standards. 3. Product testing: Conducting rigorous testing of the geogrids at various stages of production to evaluate their mechanical properties, such as tensile strength, elongation, and durability. 4. Statistical process control: Using statistical methods to monitor and control the manufacturing process, identifying any deviations from the desired quality standards and taking appropriate corrective actions. 5. Quality inspections: Conducting regular inspections of the manufacturing facilities and equipment to ensure proper maintenance and calibration, preventing any potential quality issues. 6. Traceability: Implementing a system to track and trace each batch of geogrids manufactured, ensuring accountability and facilitating prompt recall or corrective actions if necessary. 7. Continuous improvement: Regularly reviewing and analyzing quality data, customer feedback, and industry trends to identify areas for improvement and implement corrective and preventive measures. By implementing these quality control measures, geogrid manufacturers can ensure consistent production of high-quality products that meet the required standards and customer expectations.

- Q: What are the different types of geogrids?

- There are several different types of geogrids, including biaxial geogrids, uniaxial geogrids, and triaxial geogrids. Biaxial geogrids have strength in two directions and are commonly used for soil stabilization and reinforcement. Uniaxial geogrids have strength in one direction and are often used for retaining walls and steep slopes. Triaxial geogrids have strength in three directions and are primarily used for load-bearing applications such as road construction and pavement reinforcement.

Send your message to us

Self-Adhesive Bitumen Coated Fiberglass Geogrid Geocells for Driveways

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords