Geogrid Driveway

Geogrid Driveway Related Searches

Driveway Geogrid Geogrid Gravel Driveway Geogrid Grass Driveway Geogrid Driveway Installation Geogrid For Driveway Geogrid Fabric Driveway Geogrid Walkway Geogrid Road Geogrid Driveway Cost Geogrid For Driveways Geogrid For Gravel Driveway Geogrid Road Base Geogrid Parking Geogrid Road Construction Geogrid Parking Lot Road Base Geogrid Geogrid Layer Geogrid Paving Geogrid Pavement Geogrid Energy Geogrid For Roads Geogrid Slope Asphalt Geogrid Geogrid For Road Construction Geogrid Construction Geostar Geogrid Geogrid Machine Geogrid Home Depot Geogrid Walls Grass GeogridGeogrid Driveway Supplier & Manufacturer from China

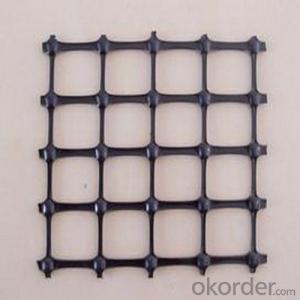

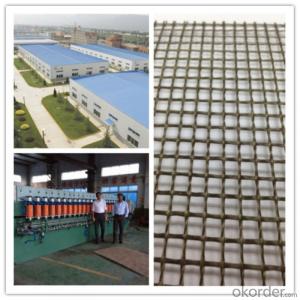

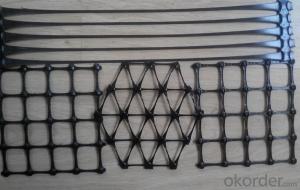

Geogrid Driveway is a high-quality product designed to provide stability and reinforcement for driveways and other ground surfaces. This innovative solution utilizes geogrid technology to distribute weight evenly, preventing soil displacement and reducing the risk of damage to the underlying structure. The application of Geogrid Driveway is extensive, as it can be used in various scenarios such as residential driveways, commercial parking lots, and even temporary access roads for construction sites. Its versatility makes it an ideal choice for a wide range of projects where ground reinforcement is required.Okorder.com is a reputable wholesale supplier that offers Geogrid Driveway to customers worldwide. With a large inventory of this product, Okorder.com ensures that clients have access to the necessary materials to complete their projects efficiently and effectively. Their commitment to quality and customer satisfaction makes them a go-to source for Geogrid Driveway and other related products.

Hot Products