PP Spunbonded Non-woven Fabric with Different Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PP Spunbonded Non Woven Fabric Introduction

Color: White,blue,green,pink,black or as customized

Material: 100% Polypropylene

Type: Spunbond Nonwoven Fabric

Width: Maximum width 240cm (can be slit)

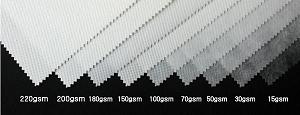

Weight: 9-200gsm

Characteristics: High quality, Stable uniformity, Adequate Weight; Soft Feeling, Eco Friendly, Recycleable, Breathable; Good Strength

Packing: Rolled with 3" paper tube inside and transparent PE bag and plastic film outside

Delivery time: 7-30 days against quantity

Payment term: TT or L/C

Application: Health, medical, industrial, household, agriculture

PP Spunbonded Non Woven Fabric Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

PP Spunbonded Non Woven Fabric After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: 5KN or 50KN

- I answered someone else on this question 1. multiply the 1.5th of the expected value of the geotextile sample by the size of the geometric cloth. 2. If you do not know the expected value, it should have a standard tensile strength range, with the tensile strength multiplied by the cross-sectional area of geotextile (thick by the width) to find the force value. 3. If you do not know, it is recommended to choose 50KN or 100KN equipment. Of course, if you need to test the geotextile was cut into a width that is particularly small, then you can use a small amount of force, but it is recommended if you choose from 5KN and 50KN election 50KN good.

- Q: What are the potential drawbacks of using geotextiles?

- Some potential drawbacks of using geotextiles include the high cost of materials and installation, limited durability in certain environments, potential for clogging due to fine particles, and difficulty in recycling or disposing of used geotextiles. Additionally, improper installation or selection of geotextiles may not provide the desired results, leading to project failure or inefficiency.

- Q: What glue glue is used at the seams of the impervious geotextile

- What glue glue is used at the seams of the impervious geotextile

- Q: What is the use of the black network when the shop is paved?

- It is geogrid, can enhance the overall strength of the roadbed, from the role of tensile, mostly polyethylene materials.

- Q: Can geotextiles be used in stormwater management systems?

- Yes, geotextiles can be used in stormwater management systems. Geotextiles are often used to enhance filtration and separation in stormwater management applications, helping to control erosion and retain sediment within the system. They can be used in various components of stormwater systems such as sediment basins, retention ponds, and biofiltration systems to improve their effectiveness and longevity.

- Q: Can geotextiles be used for reinforcement in landfills?

- Yes, geotextiles can be used for reinforcement in landfills. They are often used as a separation layer between different soil layers, providing stability and preventing the mixing of materials. Geotextiles also help in enhancing the overall strength and performance of the landfill structure by distributing loads and reducing the potential for erosion or piping.

- Q: What are the factors that affect the strength of geotextiles?

- The factors that affect the strength of geotextiles include the material composition and tensile properties of the geotextile itself, the construction and weaving techniques used, the thickness and weight of the geotextile, and the environmental conditions such as temperature, humidity, and exposure to chemicals or UV radiation. Additionally, factors such as installation methods, loadings, and the presence of any contaminants or puncture objects can also impact the strength of geotextiles.

- Q: How do geotextiles contribute to green building certifications?

- Geotextiles contribute to green building certifications by promoting sustainable construction practices. These specialized fabrics are used to enhance soil stability, control erosion, and manage stormwater runoff, resulting in improved site conditions and reduced environmental impacts. By incorporating geotextiles, construction projects can meet various criteria for green building certifications, such as water efficiency, site development, and erosion control, ultimately contributing to more sustainable and environmentally-friendly structures.

- Q: Are geotextiles suitable for use in coastal erosion control?

- Yes, geotextiles are suitable for use in coastal erosion control. They are commonly used to stabilize slopes, prevent soil erosion, and protect shorelines from wave action. Geotextiles can be installed as a barrier to filter sediment and retain soil while allowing water to pass through, effectively controlling erosion in coastal areas.

- Q: Do you need to use geotextile for construction site? Mainly used where?

- Underground garage roof green

Send your message to us

PP Spunbonded Non-woven Fabric with Different Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords