Geoweb Geocells PP Biaxial Geogrid - High Quality for Highways

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Biaxial Geogrid ( Biaxial plastix protect-support net used in coal mine ) description :

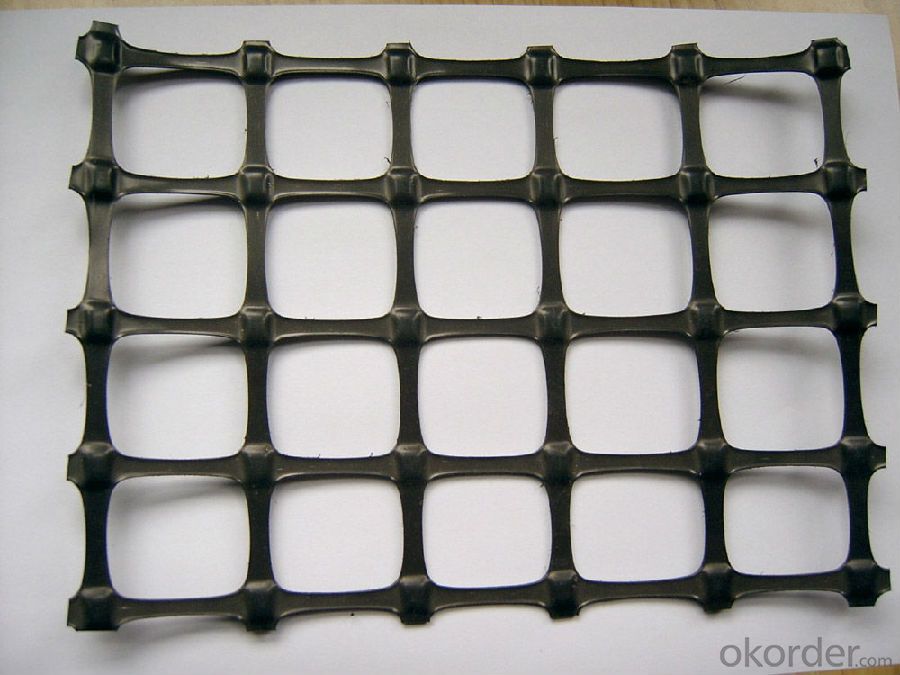

Double-direction geogrid is made of high molecular polymer through extrusion, forming and punching before longitudinal and lateral stretching. This material has considerable tensile strength in longitudinal and lateral directions. This chain structure can effectively bear and diffuse forces on soil and is applicable to large area permanent load bearing foundation as a reinforce.

Properties of Biaxial Geogrid ( Biaxial plastix protect-support net used in coal mine ):

Homogenous structure, low creepage ,anti-aging and resisting acid and alkaline.

Application of Biaxial Geogrid ( Biaxial plastix protect-support net used in coal mine ) :

Make reinforce treatment for various of soft soil foundation to evenly distribute load stress and reduce unevensettlement , it is easy to wash coal . used in highway ,railway,port,airport, municipacl and projects of supporting in the recovery working face of coal mined and ladeway in the coal mine .

Specification of Biaxial Geogrid ( Biaxial plastix protect-support net used in coal mine ) :

TGSG15-15,TGSG20-20,TGSG25-25,TGSG30-30,TGSG35-35,TGSG40-40,BP15-15MS,HPP20-20MS, HBPP25-25MS,HBPP30-30MS,HBPP35-35MS,HBPP40-40MS

Width : 1M,2M,3M,4M.

Length: 50m,100,

Color: black

Packaging & Delivery of Biaxial Geogrid ( Biaxial plastix protect-support net used in coal mine ): Each roll is wrapped in a woven bag then into container Or Packed as customers' requests.

Production periods of Biaxial geogrid : within 10 days after receiving the deposit

FAQ

1. What's the usage of geogrid?

It's used for reinforce the roadbeds in softe soil, railway and dam etc. It has good performance on preventing the cracks.

2. How about your quality of geogrid?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

- Q: Are geogrids resistant to hydrostatic pressure?

- Yes, geogrids are resistant to hydrostatic pressure. They are designed to provide structural support and reinforcement to soil, helping to distribute and reduce the pressure exerted by water or other fluids.

- Q: Can geogrids be used in reinforcement of embankments?

- Yes, geogrids can be used in the reinforcement of embankments. Geogrids are commonly used in civil engineering projects to improve the stability and strength of soil structures, such as embankments. They are designed to increase the bearing capacity of soils, redistribute loads, and prevent soil erosion. By incorporating geogrids into embankments, it helps to enhance their overall stability and prevent potential failures.

- Q: Can geogrids be used in retaining walls for industrial facilities?

- Yes, geogrids can be used in retaining walls for industrial facilities. Geogrids provide reinforcement and stability to the soil, increasing the overall strength and durability of the retaining wall. This makes them an ideal choice for industrial facilities where there may be heavy loads or high lateral pressures. Additionally, geogrids can help reduce construction costs and increase the lifespan of the retaining wall.

- Q: Can geogrids be used in erosion control applications?

- Yes, geogrids can be used in erosion control applications. Geogrids are commonly used to reinforce and stabilize slopes, retaining walls, and embankments, reducing soil erosion and preventing the loss of soil particles. They provide effective erosion control by improving the stability of the soil and preventing surface runoff, thereby helping to protect against erosion and maintain the integrity of the landscape.

- Q: Are there any specific maintenance requirements for geogrids?

- Yes, geogrids have specific maintenance requirements. They should be inspected regularly for any signs of damage or deterioration, such as tears, fraying, or disintegration. If any issues are found, appropriate repairs or replacements should be made promptly to ensure the geogrid's effectiveness. Additionally, geogrids should be kept clean and clear of any debris or vegetation that could impact their performance.

- Q: Is there a big difference between horizontal permeability and vertical permeability coefficient

- . That is to say, the permeability coefficient of geosynthetics is broad. The vertical permeability coefficient is unique to geotextiles. The test methods of permeability coefficient and vertical permeability coefficient are similar.

- Q: Can geogrids be used in ground stabilization for oil and gas facilities?

- Yes, geogrids can be used in ground stabilization for oil and gas facilities. Geogrids are highly effective in reinforcing the soil and providing stability, which is essential for supporting heavy equipment and infrastructure in these facilities. They help to prevent soil erosion, increase load-bearing capacity, and improve overall ground stability, making them a suitable solution for oil and gas facilities.

- Q: Can geogrids be used in pipeline trench stabilization applications?

- Yes, geogrids can be used in pipeline trench stabilization applications. Geogrids are commonly used in civil engineering projects to reinforce soils and provide stability. In pipeline trench stabilization, geogrids can be installed horizontally or vertically to enhance the load-bearing capacity of the soil, prevent soil erosion, and reduce the risk of ground movement. This helps in ensuring the longevity and safety of the pipeline system.

- Q: What is the market price of the geotechnical grid in 2017

- (2) 0.3m thick medium (coarse) sand, artificial with mechanical leveling, 25T vibratory roller static pressure two times.

- Q: What are the factors that affect the installation and survivability of geogrids in cold climates?

- The factors that affect the installation and survivability of geogrids in cold climates include the type and quality of geogrid material, proper preparation of the subgrade, adequate compaction of the soil, temperature variations, frost heave, snow accumulation, and freeze-thaw cycles.

Send your message to us

Geoweb Geocells PP Biaxial Geogrid - High Quality for Highways

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords