Velocity Slope Plastic PP Biaxial Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

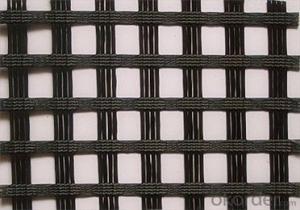

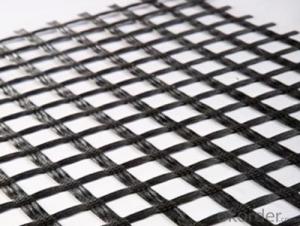

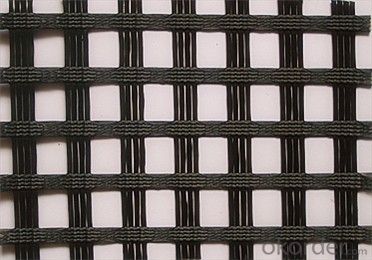

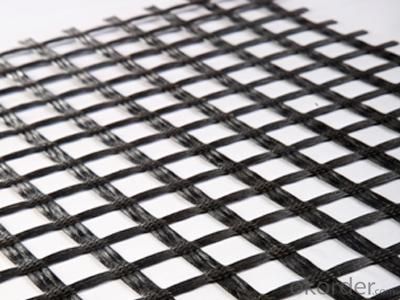

Structure of Plastic PP Biaxial Geogrid Description:

Plastic PP Biaxial Geogrid Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Main Features of Plastic PP Biaxial Geogrid :

Plastic PP Biaxial Geogrid is Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

To lay the geogrid in the backfill soil can increase the shearing strength and the whole character in middle terms, reduce the mid-term filling quantity, make the soft base more convenient, lower the construction cost.

When used in the dam design, it can be as the muscle structure to improve the bearing distortion performance of the dam to avoid breaking.

Plastic PP Biaxial Geogrid Images

Plastic PP Biaxial Geogrid Specification:

Item | Art. No. | PLB010201 | PLB010202 | PLB010203 | PLB010204 | PLB010205 |

Specs | TGDG25 | TGDG35 | TGDG50 | TGDG80 | TGDG110 | |

Unit weight,g/m2 | 370±50 | 450±50 | 550±50 | 700±50 | 1100±50 | |

Width,m | 1.0+0.2/-0 or 2.0+0.2/-0 | |||||

Tensile strength,kN/m≥ | 25 | 35 | 50 | 80 | 110 | |

Elongation,%≤ | 12 | |||||

Tensile strength at 2% strain,kN/m≥ | 6 | 9 | 10 | 23 | 30 | |

Tensile strength at 5% strain,kN/m≥ | 12 | 18 | 25 | 44 | 60 | |

Roll length,m | 50+0.25/-0 | |||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: How do geogrids help in reducing the risk of pavement rutting?

- Geogrids help in reducing the risk of pavement rutting by providing structural reinforcement to the pavement layers, improving their stability and preventing the formation of ruts. They distribute the load across a wider area, reducing the stress on the pavement surface and minimizing the deformation caused by heavy traffic or repeated loading. This helps to maintain the integrity of the pavement, increasing its lifespan and reducing the need for costly repairs or maintenance.

- Q: What is the recommended geogrid aperture shape for specific applications?

- The recommended geogrid aperture shape for specific applications varies depending on the specific requirements of the project. However, commonly used shapes include square, rectangular, and hexagonal apertures. These shapes provide different levels of stability, soil confinement, and load distribution, allowing engineers to select the most suitable option based on factors such as soil type, slope angle, and anticipated loads.

- Q: Urgent need!!

- (1) due to the existence of joints and cracks, the old cement concrete pavement as the base of the overall strength is reduced, and under the action of external forces, the asphalt overlay in the three-dimensional stress state. The vehicle passing adiscontinuous board, because the joints and cracks on both sides of the adjacent plate reflecting cracks of vertical displacement difference, asphalt overlay in the corresponding position of the larger shear stress, the shear stress is the main reason of asphalt pavement reflection cracks produced. Usually referred to as the load type reflective crack.(2) due to the exposure of the pavement in the atmosphere, the asphalt overlay and the old cement concrete face have the shrinkage and the temperature stress. Because of the Old Cement Concrete Pavement Stress in the joints is not continuous, so the asphalt overlay and bear it and the old pavement caused by temperature stress, especially under low temperature in winter, the asphalt overlay at the seams, cracks, because of excessive tensile stress and cracking formation temperature reflection crack.The mechanism of 3 glass fiber grid to restrain reflection crackThe glass fiber grid has the advantages of high tensile strength, low elongation and no creep

- Q: Are geogrids effective in stabilizing dredged material containment areas?

- Yes, geogrids are effective in stabilizing dredged material containment areas. Geogrids provide reinforcement and stability to the soil, preventing erosion and maintaining the containment of dredged material. They help distribute loads and reduce settlement, ensuring long-term stability and containment of the dredged material.

- Q: What are the different installation techniques for geogrids?

- There are several installation techniques for geogrids, including mechanical connection, soil confinement, and anchorages. Mechanical connection involves attaching the geogrid to the soil or other structures using methods like staples, nails, or screws. Soil confinement refers to placing the geogrid within the soil mass to enhance its stability and prevent lateral movement. Anchorages are used to secure the geogrid by embedding it into a stable structure or using specialized anchoring devices.

- Q: Can geogrids be used in ground improvement projects?

- Yes, geogrids can be used in ground improvement projects. Geogrids are commonly employed to reinforce and stabilize the soil layers, enhancing their load-bearing capacity. They are particularly useful in projects that involve soft or weak soils, providing increased stability and preventing soil settlement. Geogrids are also effective in preventing soil erosion and improving the overall performance of the ground.

- Q: Are there any specific requirements for geogrid installation in road construction?

- Yes, there are specific requirements for geogrid installation in road construction. Geogrids should be properly placed and secured at the correct depth and orientation to effectively reinforce the soil and distribute the load. They should be installed on a stable and properly prepared base, with adequate overlap and connection strength. Additionally, compacted fill material should be placed and compacted in layers over the geogrid to ensure proper interlocking and load transfer.

- Q: What is the tensile strength of a geogrid?

- The tensile strength of a geogrid refers to its ability to withstand pulling forces without breaking or deforming. It is typically measured in units of force per unit width, such as kilonewtons per meter (kN/m). The actual tensile strength of a geogrid can vary depending on its design, materials used, and manufacturing process.

- Q: Are geogrids suitable for use in ground reinforcement for agricultural facilities?

- Yes, geogrids are suitable for use in ground reinforcement for agricultural facilities. Geogrids provide effective soil stabilization, preventing erosion and enhancing load-bearing capacities. They are especially beneficial in areas with heavy machinery or high foot traffic, offering long-term durability and improved agricultural operations.

- Q: How do geogrids improve the performance of geosynthetic drainage systems?

- Geogrids improve the performance of geosynthetic drainage systems by providing additional structural support and stability. They enhance the load-bearing capacity of the system, preventing soil erosion and promoting effective water flow. Geogrids also distribute the weight evenly across the system, reducing the risk of localized failures and improving long-term durability.

Send your message to us

Velocity Slope Plastic PP Biaxial Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords