Plastic Geogrids for Geogrids and Soil Stabilisation Materials

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

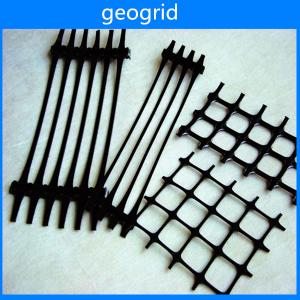

Item:PP Uniaxal geogird

1.Material:PP

2.Tensiel strength:30KN/M

3.Size:2.5m*50M

4. Elongation:10%

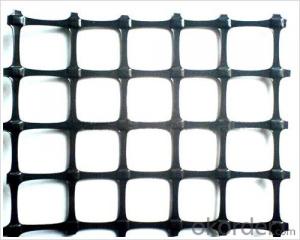

Uniaxial geogrid ,made of high molecular polymer ,is extruded into sheet and then punched into regular mesh patten,and finally stretched in the longitudinal direction.

Feature:

With high tensile strength and tensile modulus

Function:

Uniaxial goegrid is mainly applied in highway,railway,slope protecting projects,retaining wall,dam to strengthen land loading capacity and extend its service life.Features in reducing area,project cost and matentainence cost,convenient to construct.

- Q: Are geogrids suitable for use in slope stabilization for mining haul roads?

- Yes, geogrids are suitable for use in slope stabilization for mining haul roads. Geogrids are engineered materials that provide reinforcement and stability to soil, improving its load-bearing capacity. They are commonly used in various applications, including slope stabilization, to prevent soil erosion and maintain the integrity of the road. By distributing the load more evenly and reducing the potential for soil movement, geogrids enhance the safety and durability of mining haul roads.

- Q: We would like to change the geogrid reinforced geogrid, I do not know what the reason for change is more reasonable

- If you change the reinforcement, then use the lowest height of the room may be able to succeed, the geogrid thickness of only 3mm, is relatively thin, I hope you can succeed, the difficulty is also some, please take it, thank you, thank you

- Q: What are the differences between geogrids and geocells in terms of installation?

- Geogrids and geocells differ in terms of installation primarily because of their structural designs. Geogrids are typically rolled out and laid on a prepared surface, followed by anchoring them using stakes or pins. On the other hand, geocells are assembled on-site and filled with soil, aggregate, or other materials to create a stable structure. This process involves connecting individual cells and securing them together, forming a three-dimensional honeycomb-like structure. Therefore, while geogrids require relatively simpler installation techniques, geocells demand more labor and time for assembly.

- Q: I am a quality inspector, I would like to know what is the standard implementation of Geogrid

- 4:YT030 geotextile effective aperture measuring instrument5:YT040 type dynamic testing instrument for geotextiles6:YT050 type geotextile wear tester

- Q: Are geogrids effective in reducing soil erosion?

- Yes, geogrids are effective in reducing soil erosion. Geogrids are a type of synthetic material that is placed on the surface of the soil to stabilize it and prevent erosion. They create a strong and stable barrier that helps to retain the soil in place, even under heavy rainfall or slope conditions. Additionally, geogrids can enhance the strength and load-bearing capacity of the soil, making them an effective solution for erosion control in various applications such as road construction, embankments, and retaining walls.

- Q: Can geogrids be used in soil stabilization for agriculture?

- Yes, geogrids can be used in soil stabilization for agriculture. Geogrids are commonly used to reinforce soil and provide stability to various types of agricultural applications, such as retaining walls, embankments, and roads. They help to prevent soil erosion, improve load-bearing capacity, and enhance overall soil stability, making them an effective solution for soil stabilization in agricultural settings.

- Q: And specification.. Thank you for answering me

- It is estimated that which is the boring manufacturers to use basalt fiber grille

- Q: How do geogrids reduce settlement in embankments?

- Geogrids reduce settlement in embankments by increasing the stability and load-bearing capacity of the soil. They distribute the applied load over a larger area, thus reducing the stress on the soil and minimizing settlement. Additionally, geogrids improve soil compaction and prevent lateral movements, thereby enhancing the overall integrity and longevity of the embankment.

- Q: Are geogrids resistant to chemical attack?

- Yes, geogrids are generally resistant to chemical attack. They are made from high-strength polymers or other materials that have a high resistance to chemical degradation. This makes geogrids suitable for use in various environments, including those where exposure to chemicals is a concern. However, the specific chemical resistance of a geogrid may vary depending on the type of polymer used. It is recommended to consult the manufacturer's specifications or conduct appropriate testing to ensure compatibility with specific chemicals.

- Q: Are geogrids easy to install?

- Yes, geogrids are relatively easy to install. They can be installed using simple tools and equipment, and the process generally involves unrolling the geogrid, securing it in place, and covering it with soil or aggregate material. However, the ease of installation can vary depending on the specific project and site conditions.

Send your message to us

Plastic Geogrids for Geogrids and Soil Stabilisation Materials

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords