All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

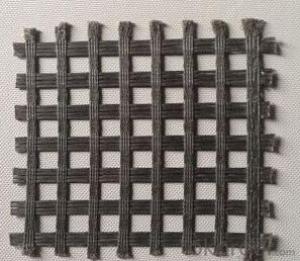

How do geogrids affect load distribution in geosynthetic railway ballast systems?

Geogrids play a significant role in enhancing load distribution in geosynthetic railway ballast systems. They are designed to improve the stability and performance of the ballast layer by distributing the load applied to the track more evenly. By interlocking with the ballast stones, geogrids provide reinforcement and increase the bearing capacity of the track. This helps to prevent ballast deformation, track settlement, and differential settlement, ensuring a more uniform distribution of load across the system. Ultimately, geogrids help to improve the longevity and functionality of railway ballast systems.

What are the key advantages of using geogrids in construction projects?

Some key advantages of using geogrids in construction projects include increased soil reinforcement, improved load distribution, reduced lateral movement of soil, and enhanced overall stability of structures. Geogrids can also help minimize the need for excavation and provide cost savings by allowing for the use of less expensive fill materials. Additionally, they can help prevent soil erosion and maintain the integrity of the project over time.

What are the benefits of using geogrids in road construction?

Geogrids offer several benefits in road construction. Firstly, they enhance the stability and strength of the road by providing reinforcement to the soil, preventing its lateral movement and improving load-bearing capacity. Secondly, geogrids help in the distribution of stress and load across the road surface, reducing the risk of cracks and potholes. Additionally, these materials increase the lifespan of the road by minimizing the effects of traffic-induced wear and tear. Finally, geogrids can also reduce construction costs by allowing for thinner road layers and reducing the need for expensive construction materials like aggregate. Overall, geogrids prove to be a cost-effective and efficient solution in road construction projects.

What is the lifespan of a geogrid?

The lifespan of a geogrid can vary depending on factors such as the quality of the material, the environmental conditions it is exposed to, and the level of stress it undergoes. However, on average, geogrids are designed to have a lifespan of around 50 to 100 years.

Wholesale Geogrids from supplier in Chad

With our expertise in supplying Geogrids in Chad, we offer a wide range of high-quality products that meet various project requirements. Whether you need Geogrids for soil stabilization, reinforcement, or erosion control, we have the perfect solution for you.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide seamless procurement services. Our team is dedicated to delivering exceptional customer support, ensuring that you receive the right products at competitive prices.

In addition to sales and pricing support, we also provide technical assistance to help you make informed decisions. Our experts have a deep understanding of the Chad market, offering valuable insights and guidance for your projects.

With years of experience in the industry, we have developed strong relationships with reliable suppliers, ensuring that you receive top-quality Geogrids that meet international standards. We value customer satisfaction and strive to exceed your expectations in every aspect of our service.

Choose us as your Geogrids supplier in Chad and experience the difference our expertise and commitment can make in delivering successful outcomes for your projects. Contact us today to discuss your requirements or request a quote.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide seamless procurement services. Our team is dedicated to delivering exceptional customer support, ensuring that you receive the right products at competitive prices.

In addition to sales and pricing support, we also provide technical assistance to help you make informed decisions. Our experts have a deep understanding of the Chad market, offering valuable insights and guidance for your projects.

With years of experience in the industry, we have developed strong relationships with reliable suppliers, ensuring that you receive top-quality Geogrids that meet international standards. We value customer satisfaction and strive to exceed your expectations in every aspect of our service.

Choose us as your Geogrids supplier in Chad and experience the difference our expertise and commitment can make in delivering successful outcomes for your projects. Contact us today to discuss your requirements or request a quote.