All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

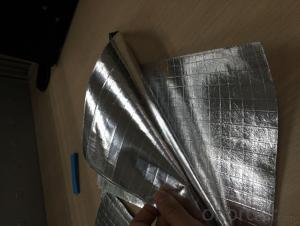

What are the different manufacturing processes for aluminum foil facing?

There are several manufacturing processes for producing aluminum foil facing. The most common method is called rolling, which involves passing aluminum ingots through a series of rolling mills to gradually reduce the thickness and create a continuous sheet of foil. Another process is called continuous casting, where molten aluminum is cooled and solidified into thin sheets. Additionally, some manufacturers use a combination of rolling and annealing processes to further enhance the foil's properties.

Can aluminum foil facing be used in conjunction with radiant floor heating systems?

Yes, aluminum foil facing can be used in conjunction with radiant floor heating systems. It acts as a reflective barrier, helping to direct the heat upwards and improve the overall efficiency of the system.

How does aluminum foil facing affect the energy efficiency of a building?

Aluminum foil facing can significantly improve the energy efficiency of a building. When installed as a radiant barrier, it reflects heat back towards its source, preventing it from entering or escaping the building. This reduces the need for excessive heating or cooling, thus lowering energy consumption and costs. Additionally, aluminum foil facing can also act as a vapor barrier, preventing moisture infiltration and enhancing overall insulation effectiveness.

What are the cost implications of using aluminum foil facing in insulation projects?

Using aluminum foil facing in insulation projects can have both cost advantages and disadvantages. On the one hand, aluminum foil is a relatively inexpensive material, making it a cost-effective choice for insulation applications. Additionally, it can enhance the thermal performance of insulation by reflecting heat back into the living space.

However, there are also cost implications to consider. Aluminum foil facing may require additional installation steps and materials, such as adhesives or fasteners, which can increase the overall project cost. Moreover, if not properly installed or maintained, aluminum foil can be prone to tears, reducing its effectiveness and potentially leading to higher energy costs in the long run.

Therefore, while aluminum foil facing can offer cost savings and improved thermal performance, it is essential to carefully evaluate the specific project requirements and consider both upfront and long-term costs before making a decision.

Wholesale Aluminum Foil Facing from supplier in Chad

Whether you require Aluminum Foil Facing for insulation purposes or packaging applications, we have the right solution for you. Our products are manufactured using high-quality aluminum foil combined with advanced technology, ensuring excellent thermal insulation, moisture resistance, and durability.

In addition to supplying Aluminum Foil Facing, we also offer customized solutions to meet specific project requirements. Our team of experts is dedicated to providing personalized support and guidance throughout the procurement process. We understand the unique challenges faced by customers in Chad and are committed to delivering products that meet your exact specifications.

Furthermore, our technical support services are designed to assist you in selecting the most suitable Aluminum Foil Facing products for your applications. Whether you need assistance in understanding product specifications, installation techniques, or troubleshooting, our knowledgeable team is ready to help.

As a subsidiary of CNBM, a globally recognized company, we have access to a vast network of suppliers and resources. This enables us to offer competitive prices and timely delivery for all your Aluminum Foil Facing needs in Chad. We prioritize customer satisfaction and strive to exceed your expectations in every aspect of our services.

Contact us today to discuss your Aluminum Foil Facing requirements in Chad. Our dedicated team is ready to assist you with sales, quotations, and technical support, ensuring a seamless procurement experience. Trust us to be your reliable partner for all your Aluminum Foil Facing needs in Chad.

In addition to supplying Aluminum Foil Facing, we also offer customized solutions to meet specific project requirements. Our team of experts is dedicated to providing personalized support and guidance throughout the procurement process. We understand the unique challenges faced by customers in Chad and are committed to delivering products that meet your exact specifications.

Furthermore, our technical support services are designed to assist you in selecting the most suitable Aluminum Foil Facing products for your applications. Whether you need assistance in understanding product specifications, installation techniques, or troubleshooting, our knowledgeable team is ready to help.

As a subsidiary of CNBM, a globally recognized company, we have access to a vast network of suppliers and resources. This enables us to offer competitive prices and timely delivery for all your Aluminum Foil Facing needs in Chad. We prioritize customer satisfaction and strive to exceed your expectations in every aspect of our services.

Contact us today to discuss your Aluminum Foil Facing requirements in Chad. Our dedicated team is ready to assist you with sales, quotations, and technical support, ensuring a seamless procurement experience. Trust us to be your reliable partner for all your Aluminum Foil Facing needs in Chad.