Miragrid Gx Fiberglass Geogrids for Base Stabilization

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Manufacturer for Base Stabilization

Description Of Fiberglass Geogrid Manufacturer for Base Stabilization:

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance.The products after surface covering own the favorable property of alkali resistance and aging resistance. It is used widely to increase the asphalt road surface, concrete road and roadbed (both soft and hard road surfaces). Compared with the traditional road surface, it reduces the cost, prolong the service life, and avoid the reflection road crackle. This product is also used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, etc, and the roadbed.

Main Features of Fiberglass Geogrid Manufacturer for Base Stabilization:

1.High tensile strength, low elongation.

2.No long-term creep: the product can keep for a long time performance.

3.Thermal stability: fiber glass melting temperature above 1000 ℃.

4.The compatibility with asphalt.

5.Physical and chemical stability.

Specifications of Fiberglass Geogrid Manufacturer for Base Stabilization:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid Manufacturer for Base Stabilization:

Strengthen bitumen concrete roadway and reduce and prevent various kinds of reflection gaps on roadway.

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

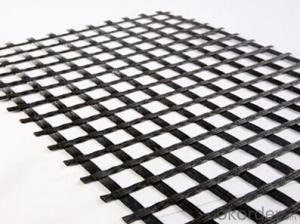

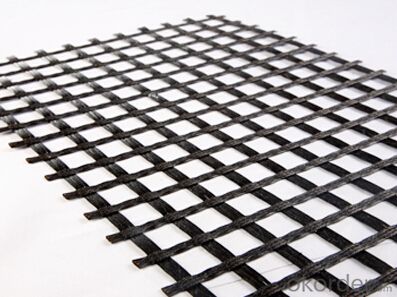

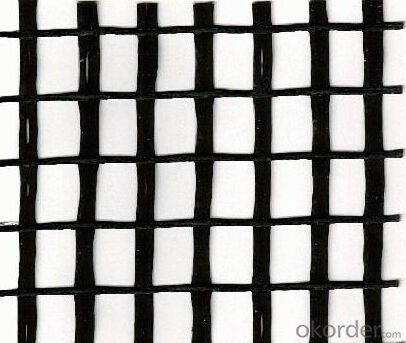

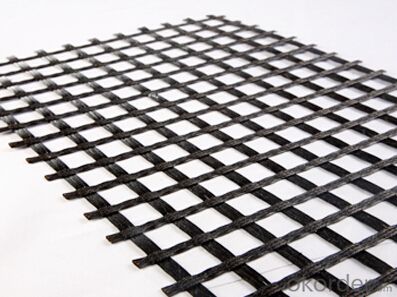

IMages of Fiberglass Geogrid Manufacturer for Base Stabilization:

FAQ of Fiberglass Geogrid Manufacturer for Base Stabilization:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: How are geogrids installed?

- Geogrids are typically installed by first clearing and grading the surface, then placing a layer of geotextile fabric on the ground. The geogrid is then laid on top of the fabric and secured using stakes or pins. Additional layers of geotextile fabric and fill material may be added as needed, and the geogrid is often connected or overlapped to create a continuous reinforcement layer. Finally, the fill material is compacted over the geogrid to provide stability and support.

- Q: Can geogrids be used in shoreline protection?

- Yes, geogrids can be used in shoreline protection. Geogrids are commonly used to stabilize and reinforce soil, including in coastal areas. They can provide erosion control, improve soil stability, and enhance the overall resilience of shorelines against waves and tidal forces.

- Q: Can geogrids be used in reinforcement of embankments?

- Yes, geogrids can be used in the reinforcement of embankments. Geogrids are commonly used in civil engineering projects to improve the stability and strength of soil structures, such as embankments. They are designed to increase the bearing capacity of soils, redistribute loads, and prevent soil erosion. By incorporating geogrids into embankments, it helps to enhance their overall stability and prevent potential failures.

- Q: Dimensions of U shaped steel nails for geogrids

- U type nails, like the letter U, geogrid generally 0.6 multiplied by 80. You can also process.

- Q: Can geogrids be used in green roof systems?

- Yes, geogrids can be used in green roof systems. Geogrids provide reinforcement and stability to the soil and vegetation layers of a green roof, preventing soil erosion and enhancing the structural integrity of the system. They can help distribute the weight of the green roof evenly, reduce the risk of subsidence, and improve overall performance and longevity.

- Q: Can geogrids be used in soil stabilization for agriculture?

- Yes, geogrids can be used in soil stabilization for agriculture. Geogrids are commonly used in various soil stabilization applications, including agriculture, to improve soil strength, prevent erosion, and enhance load-bearing capacity. They help in stabilizing the soil by providing reinforcement and distributing loads, which is essential for promoting healthy crop growth and preventing soil erosion in agricultural lands.

- Q: Can geogrids be used in ground reinforcement for military installations?

- Yes, geogrids can be used in ground reinforcement for military installations. Geogrids are often employed in various civil engineering applications, including military projects, to enhance soil stability, provide load-bearing support, and improve overall ground reinforcement. They are effective in reinforcing and stabilizing soil, which is essential for military installations that require durable and resilient foundations to withstand heavy equipment, traffic, and potential ground disturbances. Geogrids can also assist in reducing soil erosion, enhancing slope stability, and minimizing the risk of ground movement or settlement, making them a valuable tool in military construction and infrastructure projects.

- Q: Can geogrids be used in road construction?

- Yes, geogrids can be used in road construction. Geogrids are commonly used in road construction for reinforcement of the soil, improving the stability and load-bearing capacity of the road. They are often used to reduce cracking and rutting, enhance pavement performance, and increase the overall lifespan of the road.

- Q: High density polyethylene one-way geogrid, tensile yield of 20kn/m

- NamelyUnidirectional geogrid with tensile yield of 20kn/m

- Q: Are there any environmental concerns associated with geogrids?

- Yes, there are a few environmental concerns associated with geogrids. The production of geogrids involves the use of non-renewable resources and energy, which contributes to carbon emissions and environmental degradation. Additionally, the disposal of geogrids after their useful life can pose challenges as they are often not biodegradable and may end up in landfills. However, when used properly and managed responsibly, geogrids can still provide environmental benefits such as erosion control and soil stabilization.

Send your message to us

Miragrid Gx Fiberglass Geogrids for Base Stabilization

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords