Asphalt Reinforcement Geogrids - Fiberglass Geogrid with Bitumen Coated for Base Stabilization

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid with Bitumen Coated for Base Stabilization

Description Of Fiberglass Geogrid with Bitumen Coated for Base Stabilization:

1. A kind of planar mesh material using alkali-free fiberglass yarn as base body and

then coated with high quality modified asphalt.

2. Warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant.

3. Coated with asphalt making full protection of the fiberglass matrix and greatly

improving its wear and shear resistance.

4. Having a good performance in pavement strengthening, track cracking and solving

difficulties of strengthening the bituminous pavement.

Main Features of Fiberglass Geogrid with Bitumen Coated for Base Stabilization:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications of Fiberglass Geogrid with Bitumen Coated for Base Stabilization:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

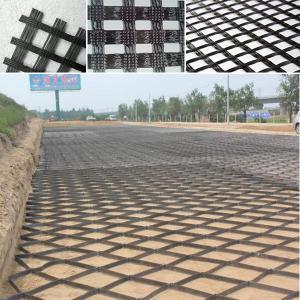

Applications of Fiberglass Geogrid with Bitumen Coated for Base Stabilization:

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

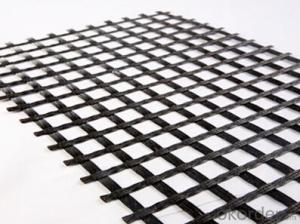

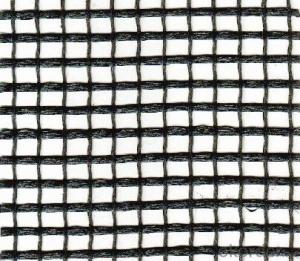

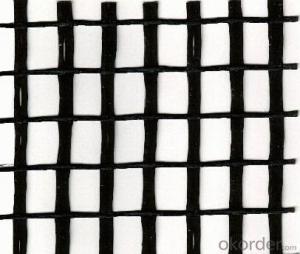

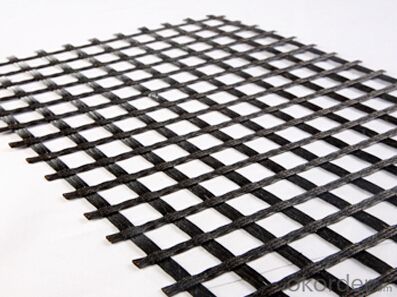

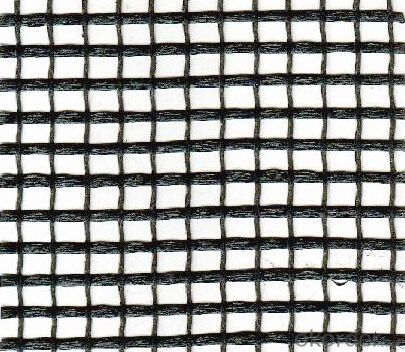

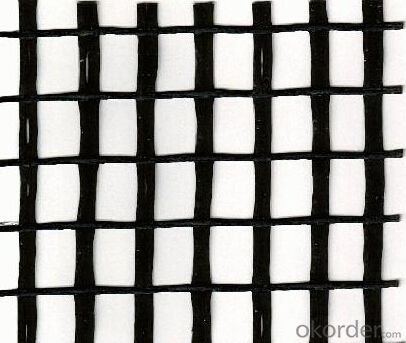

IMages of Fiberglass Geogrid with Bitumen Coated for Base Stabilization:

FAQ of Fiberglass Geogrid with Bitumen Coated for Base Stabilization:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: How do geogrids improve the stability of levees?

- Geogrids improve the stability of levees by providing reinforcement and increased tensile strength to the soil. These grid-like structures are placed within the levee's soil layers, creating a stable and cohesive system. The geogrids distribute the applied loads more evenly and prevent soil erosion, enhancing the overall stability and strength of the levee structure.

- Q: What are the types of Geogrid

- There are many types of geogrid is about tgsg / convex node tgsg / whole tgsg / glass fiber geogrid

- Q: Are geogrids effective in reducing soil erosion?

- Yes, geogrids are effective in reducing soil erosion. Geogrids are a type of synthetic material that is placed on the surface of the soil to stabilize it and prevent erosion. They create a strong and stable barrier that helps to retain the soil in place, even under heavy rainfall or slope conditions. Additionally, geogrids can enhance the strength and load-bearing capacity of the soil, making them an effective solution for erosion control in various applications such as road construction, embankments, and retaining walls.

- Q: Are geogrids resistant to chemical attack from soil contaminants?

- Yes, geogrids are generally resistant to chemical attack from soil contaminants.

- Q: How do geogrids help in preventing differential settlement?

- Geogrids help in preventing differential settlement by providing reinforcement and stability to the soil layers. They distribute the load evenly across the foundation, reducing the differential settlement potential. Additionally, geogrids improve the soil's bearing capacity and increase its shear resistance, minimizing differential settlement risks.

- Q: Are geogrids suitable for coastal engineering projects?

- Yes, geogrids are suitable for coastal engineering projects. They are commonly used to reinforce and stabilize coastal structures such as seawalls, breakwaters, and revetments. Geogrids provide excellent soil reinforcement, preventing erosion and enhancing the stability of coastal structures in the face of wave action and tidal forces. Furthermore, their high tensile strength and durability make them ideal for withstanding the harsh marine environment.

- Q: What are the factors that affect the installation and survivability of geogrids in cold climates?

- The factors that affect the installation and survivability of geogrids in cold climates include the type and quality of geogrid material, proper preparation of the subgrade, adequate compaction of the soil, temperature variations, frost heave, snow accumulation, and freeze-thaw cycles.

- Q: Can geogrids be used in slope stabilization for railway cuttings?

- Yes, geogrids can be used in slope stabilization for railway cuttings. Geogrids are commonly used to reinforce soil and prevent slope failures or erosion. By installing geogrids within the slope, they help distribute the forces acting on the soil and provide increased stability. This makes geogrids an effective solution for slope stabilization in railway cuttings, where the stability of the slope is crucial for the safety and functionality of the railway infrastructure.

- Q: How do geogrids improve the performance of paved and unpaved roads?

- Geogrids improve the performance of paved and unpaved roads by providing reinforcement and stabilization to the soil and pavement layers. They distribute loads more evenly, reducing the formation of cracks and potholes. Geogrids also enhance the tensile strength of the road, allowing it to withstand heavier traffic and minimize deformation. Overall, geogrids increase the durability, lifespan, and structural integrity of both paved and unpaved roads.

- Q: Do geogrids increase the bearing capacity of soil?

- Yes, geogrids can increase the bearing capacity of soil. Geogrids are materials made of polymers or metals that are used to reinforce soil. They help distribute the load more evenly, reducing the stress on the soil and increasing its ability to bear heavier loads.

Send your message to us

Asphalt Reinforcement Geogrids - Fiberglass Geogrid with Bitumen Coated for Base Stabilization

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords