Retaining Wall Geogrid

Retaining Wall Geogrid Related Searches

Retaining Wall With Geogrid Geogrid Fabric Retaining Wall Retaining Wall Geogrid Hdpe Uniaxial Geogrid Using Geogrid Retaining Walls Geogrid Walls Geogrid Uniaxial Retaining SoilHot Searches

Geogrid Fabric For Sale Tensar Geogrid For Sale Geogrid For Sale Home Depot Geogrid Geogrid Home Depot Tensar Geogrid Distributors Tencate Geogrid Geogrid Near Me Geogrid Comparison Chart Geogrid Comparison Geogrid Lowe's Tenax Geogrid Tensar Bx1100 Geogrid Tensar Bx1200 Geogrid Tensar Geogrid Bx1100 Tensar Geogrid Tx140 Tensar Triax Tx130s Geogrid Tensar Triax Tx140 Geogrid Tensar Triax Tx160 Geogrid Tensar Uniaxial GeogridRetaining Wall Geogrid Supplier & Manufacturer from China

Okorder.com is a professional Retaining Wall Geogrid supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Retaining Wall Geogrid firm in China.Hot Products

FAQ

- Geogrids improve the performance of geosynthetic clay liners by enhancing their tensile strength and reducing lateral movement or deformation. The geogrids act as a reinforcement layer, providing additional stability and support to the clay liner. This helps to prevent cracking, shifting, and erosion of the liner, ultimately enhancing its overall performance and durability.

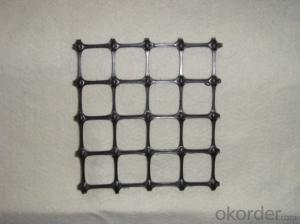

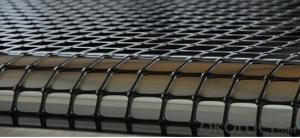

- Yes, geogrids are generally resistant to moisture absorption. They are made from materials such as high-density polyethylene (HDPE) or polyester, which have inherent moisture resistance properties. This resistance to moisture absorption helps to maintain the stability and strength of geogrids in various construction and civil engineering applications.

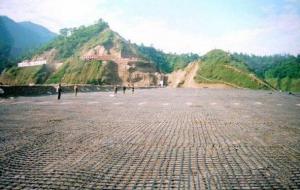

- Yes, geogrids can be used in ground improvement projects. Geogrids are commonly used to reinforce and stabilize soil, improving its bearing capacity and preventing soil erosion. They are effective in a variety of ground improvement applications such as road construction, retaining walls, and slope stabilization.

- Geotextiles and geogrids to do the re inspection approach?

- If necessary, geotextile and geogrid materials are qualified. But it depends on the situation.

- There are several factors that affect the design and selection of geogrids for geosynthetic reinforcement of steep slopes. These factors include the slope angle, soil type and properties, anticipated loads and stresses, project objectives, and budget constraints. Additionally, site-specific conditions such as climate, drainage, and vegetation should be considered. Properly considering these factors ensures that the selected geogrids are suitable for the specific slope reinforcement needs, providing stability, erosion control, and long-term durability.

- Yes, geogrids can be used in mining haul roads. Geogrids are commonly used in the construction of haul roads in mining operations to improve road stability, increase load-bearing capacity, and reduce maintenance costs. They provide reinforcement and stabilization to the road base, preventing deformation and rutting caused by heavy mining vehicles.

- Geogrids improve the performance of mechanically stabilized slopes under dynamic loading by enhancing the stability and strength of the slope. They act as reinforcement by distributing the applied dynamic loads more evenly, reducing stress concentrations and preventing localized failures. Additionally, geogrids increase the frictional resistance between soil particles, improving the overall shear strength and preventing slope movement or failure.

- Yes, geogrids can be used in the reinforcement of bridge approach embankments over soft soils. Geogrids are commonly used to improve the stability and strength of soil structures, including embankments, by providing reinforcement and reducing deformation. By distributing loads and increasing soil bearing capacity, geogrids can effectively mitigate settlement and prevent failure in bridge approach embankments built on soft soils.