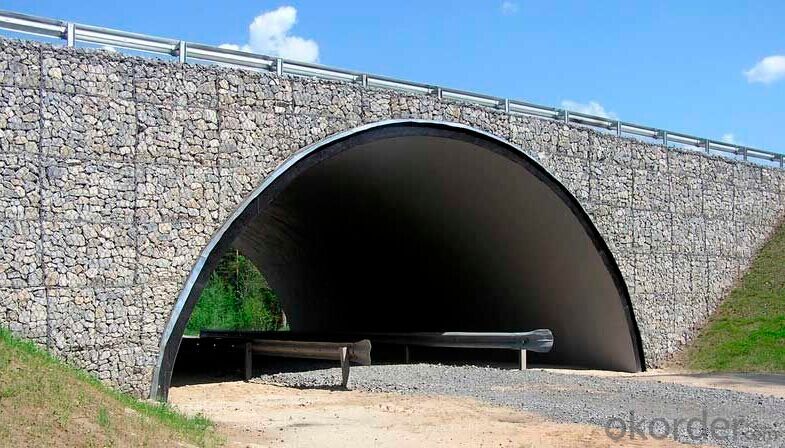

Welded Gabion Cage Retaining Gabion Wall / Gabion Cage

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Top manufacturer Welded Wire mesh gabion wholesale

1. Welded Wire mesh gabion wholesale from our factory

gabion box are more than ten years to manufacture and export Gabion box, Mainly market: Africa, America, South Africa and throughout the world

2. Welded Wire mesh gabion wholesale gabion box

Gabion is a mesh case made of galvanized wire and PVC coating wire .Gabion baskets and panels produced from galvanized wire welded mesh and HDPE and PVC on heavily Galvanized or Galfan coated wire welded mesh

3. Welded Wire mesh gabion wholesale Feature:

- Easy Assembly: Just need Heavy duty gloves & Pliers for locking spirals and stiffeners are ready

- Longer life: 20years life for Galvanized wire and more than 100years for PVC coated and stainless

- Ultimate design: More design options Can be installed any place.

4.Welded Wire mesh gabion wholesale widely application

The uses for welded mesh gabions are almost endless from artistic and architectural to purely

functional. Typical projects include

- House walls

- Garden seating

- Mail box

- Water Feature

- Fireplaces

- Pizza oven

- Planters

- and a lot more...

5.Welded Wire mesh gabion wholesale Specification as following checking:

| Gabion Box Size (L x W x H) | No. of diaphragms (Number) | Rocks required approx, (Unit: Ton) | Aperture (Opening size) |

| 2m x 1m x 1m | 1 | 4 | 75mm x 75mm 100mm x 50mm (Also available in) 50mm x 50mm 50mm x 25mm |

| 2m x 0.5m x 0.5m | 1 | 1 | |

| 1m x 1m x 0.5m | 0 | 1 | |

| 1m x 0.5m x 0.5m | 0 | 0.5 | |

| 0.5m x 0.5m x 0.5m | 0 | 0.25 | |

| Galvanized or Galfan wire :4mm (Also available in 3.2mm & 5mm) | |||

| PVC Wire: 2.7mm/3.7mm, 3/4mm (before/after PVC coating) | |||

- Q: What is the process of the screen printing process?

- Screen printing is a direct printing method, there are three kinds of process arrangements: ① cardboard → screen printing → finishing, that is, first in the corrugated cardboard or other cardboard screen printing, and then produced into cartons, carton products;

- Q: Screen printing, how to print circular arc surface

- In the net below the pad a sponge than the thickness of the screen slightly higher, the size of the sponge larger than the text part of the ink will be adjusted after the screen set off, evenly coated on the sponge.

- Q: The difference between screen printing characteristics

- Advertising, curtains, curtains. For example, the current general offset printing, embossing and other printing methods can print the size of the largest size of the whole sheet, more than the full size, it is subject to mechanical equipment restrictions.

- Q: What is the commonly used mapping software for screen printing?

- Screen printing commonly used mapping software can be used CorelDRAW, is a special vector graphics production software.

- Q: Screen printing and screen printing plate on the photosensitive material What are the requirements

- Printing equipment is simple, the operation will be printed, the plate is simple and the low cost of adaptability strong Chinese printing applications wide range of prints: color oil painting,

- Q: Screen printing ink firmness problem

- If not enough, it can only change solvent-based ink, the solvent ink tension is small, ink layer spread, drying speed, adhesion will be much better, but the volatile substances on the human body and the environment is harmful, and flammable and explosive, need

- Q: Screen printing, how to choose the screen

- Textile printing using 60-135 mesh, oily ink in plastic / metal, etc. hard surface printing using 100-180 mesh, printed circuit board use more than 200.

- Q: How to make screen printing layout smooth

- Paint the (pattern) paint, repeat it several times and check that the pattern is transparent. If the number of prints is not large, the back generally do not need to paint.

- Q: What is the screen printing plate?

- Is a certain tension by the tension of the screen after the tension on a frame, and then coated with a photoresist on the top and then with a specific pattern of film with UV light after the light washed out of the pattern made of water.

- Q: What is the principle of screen printing?

- Screen printing is the need to print the text / image through the sensor in the silk (now chemical fiber, mainly polyester fiber) online screen.

Send your message to us

Welded Gabion Cage Retaining Gabion Wall / Gabion Cage

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords