H20 Timber Beam Formwork with Single Side Bracket for Retaining Wall

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

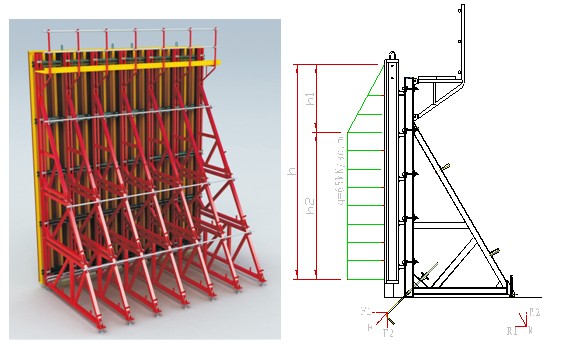

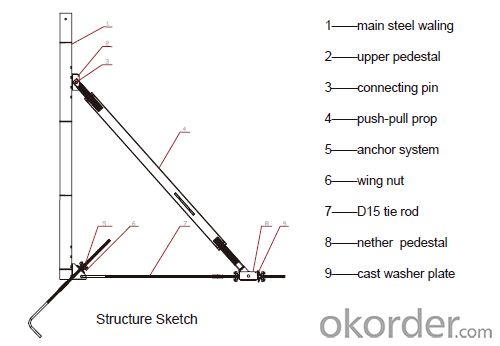

1. Structure of H20 Timber Beam Formwork with Single Side Bracket

During single-sided concrete wall construction, the concrete pressure is transferred into the sub-structure by means of the single-side bracket.

There is no wall-through tie-rod in the single-side bracket system. The whole system is adjusted by the anchor system and the regulator system.

The stress situation from the sketch above.F1 can resist the side pressure of the concrete and F2 can resist the rising force. R can not only bear the gravity force of the bracket, but also the side pressure of the concrete. This stress system is simple, reasonable and also with convenience and high safety.

2. Main Features of H20 Timber Beam Formwork with Single Side Bracket

1. The pouring height is up to 8.0m and the allowable pressure from fresh concrete is up to a maximum of 60KN/m2.

2. Good standard performance and versatility.

3. Fast element coupling, all units can be quickly connected.

4. The finished wall is excellent and absolutely waterproof.

5. Optimized sizes for transportation.

3. H20 Timber Beam Formwork with Single Side Bracket Images

4. H20 Timber Beam Formwork with Single Side Bracket Specification

5. FAQ of H20 Timber Beam Formwork with Single Side Bracket

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

We can design the artwork for you.

Please feel free to customize.

2) What promises can be done by us?

If interested in H20 Timber Beam Formwork with Single Side Bracket, please feel free to write us for any QUOTE.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days. Other mass qty of H20 Timber Beam Formwork with Single Side Bracket, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: How to prevent the template support collapsed

- Second, pay close attention to promulgated the "construction template engineering safety technical specifications." In the design calculation, it is necessary to determine the load combination according to the most unfavorable principle in order to solve the problem of the foundation deformation and the overall stability in order to ensure that the template support is the geometric invariant system ; In the quality of steel pipe fasteners to be strictly controlled, and develop practical quality inspection and acceptance methods. The following are the same as the "

- Q: The template supports how security issues are under the supervision notice

- You 1 1 rectification, and then follow the results of the rectification of the truth. You do not rectification, reply to the supervision will still give you back, or else people will not send a notice. Do a good job to do a good attitude, especially involved in security issues. Since the supervision issued to you is a security notice, that things are more serious. Now you are doing is: one by one in a regular manner in accordance with the requirements of the field rectification, rectification after the end of a written reply to close the notice.

- Q: Roof plate support combination structure

- The overall unit of light weight, easy to use the workers, but also reduce the cost. Roof plate support instead of the use of the wooden side, the number of wheel rotation is up to 300 times, excellent re-use rate.

- Q: Construction side without approval without authorization after removal of pouring with the template, what kind of remedial measures should be taken Thank you!

- When the concrete scaffolding is actually used to support the upper structure, to the concrete conservation period is allowed to remove the general is more than the demolition, and then used in the above level, indoor support with the steel scaffolding does not meet the requirements of the scaffolding decoration, interior decoration With the full scaffolding in the decoration when re-erected. Outdoor scaffolding in the pouring concrete can be erected when the masonry and decoration.

- Q: How to use template support?

- This picture is marked on the non-adjustable support, and now generally use adjustable height support.

- Q: How is the identification of tall template works?

- Large template support system refers to the construction of the construction site concrete component template support height of more than 8m, or erection span of more than 18m, or the total load of more than 15kN / ㎡, or concentrated line load greater than 20kN / m template support system.

- Q: The use of new type of shear wall template support structure cost and rental cost

- Single-storey building area of 600 square meters, 30 layers, 3 meters high, single building 30 layer * 600 square meters = 18000 square meters; shear wall development area (dip gray surface) by construction area to take 2 times, Meter * 2 = 1200 square meters * 20 kg = 24 tons * 4900 yuan = 117600 yuan.

- Q: What is a template for pulling bolts

- To the stencil fixed, a two-headed round bar, insert the template, the two tied to the nut

- Q: Template Support System Safety Control

- Strengthen construction management. Including the strengthening of the template support system technology management and security management. Template support system should be designed after the first construction. Strictly in accordance with the template design technical program to operate, are not allowed to change, if there are problems, must be approved by the template designer or by the technical director at the approval of a higher level before proceeding. Steel pipe should be checked before use, excessive deformation and serious wear and tear of the steel pipe shall not be used.

- Q: Main and vice keel upgrade modification - the new building template support birth opportunity

- Now too many products are updated, not that the traditional bad, but we should take its essence, to its dregs. On the basis of the traditional to do some changes, closer to our present habits, the use of habits. Times in the development of information in the explosion, then our products are also big step forward. Our new roof support is composed of the main keel, vice keel, supporting the mandrel, the cross bar, the main keel can be free to stretch, to meet the size of different rooms, this advantage is that a different layer can be satisfied, do not need Too many specifications, simple operation, versatility. And with a card slot and vice keel connection, is to prevent the main and vice keel sliding between.

Send your message to us

H20 Timber Beam Formwork with Single Side Bracket for Retaining Wall

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords