H20 Timber beam formwork with single side bracket

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

concrete wall formwork

retaining wall formwork

permanent formwork systems

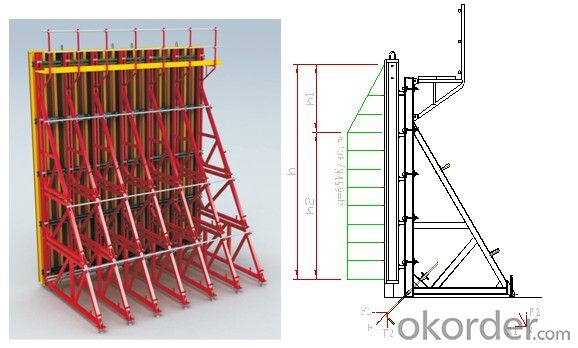

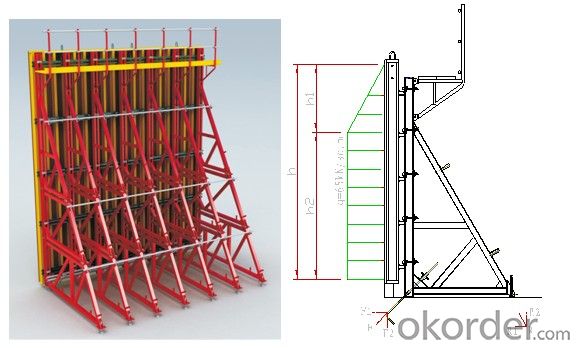

During single-sided concrete wall construction, the concrete pressure is transferred into the sub-structure by means of the single-side bracket.

Design Principle:

There is no wall-through tie-rod in the single-side bracket system. The whole system is adjusted by the anchor system and the regulator system.

The stress situation from the sketch above.F1 can resist the side pressure of the concrete and F2 can resist the rising force. R can not only bear the gravity force of the bracket, but also the side pressure of the concrete. This stress system is simple, reasonable and also with convenience and high safety.

Competitive Advantage:

1. The pouring height is up to 8.0m and the allowable pressure from fresh concrete is up to a maximum of 60KN/m2.

2. Good standard performance and versatility.

3. Fast element coupling, all units can be quickly connected.

4. The finished wall is excellent and absolutely waterproof.

5. Optimized sizes for transportation.

Applications:

- Q: Scaffolding structure template support frame type

- According to the horizontal structure of the situation: 1) horizontal structure layer is not set or a small set of diagonal bar or shear support frame; 2) 1 or several horizontal reinforcement layer set the support frame In addition, single double row support frame (Such as brackets) and not set the points, the latter's support height should not be greater than 4m. Support frame load is generally vertical load, but the box-based template (wall template) support frame at the same time by Vertical and horizontal loads.

- Q: More than a certain size of the larger risk of the template works and support system which include

- Various types of tool-based template works: including sliding mode, climbing mold, large mold, flying mold and other projects

- Q: Construction side without approval without authorization after removal of pouring with the template, what kind of remedial measures should be taken Thank you!

- In the construction process, some of the engineering found that the template full support frame if the post-pouring in the separate support, due to the longer after the pouring set, in the demolition of the full scaffolding on the post-pouring support at the greater impact of workers It is difficult to guarantee that the support system is independent and intact.

- Q: Bridge template support bowl button steel pipe scaffolding, need to set sweeping pole?

- Sweeper: part of the scaffolding project, the sweeping pole is 200mm from the ground, the horizontal bar connecting the base of the pole. Divided into vertical and horizontal sweeping pole, play a stable scaffolding effect. Vertical sweeping rods: sweeping rods arranged longitudinally along the scaffolding; horizontal sweeping rods: sweeping rods arranged horizontally along the scaffolding; lateral sweeping rods are passed under the longitudinal sweeping rods and passed through the lateral sweeps to the base.

- Q: How to use template support?

- This picture is marked on the non-adjustable support, and now generally use adjustable height support.

- Q: What is the difference between a full-screen stent and a floor-mounted stent?

- Floor support the fulcrum is the ground, that is, at least to ensure that the ground to do hardening, the local at least can withstand the support of the vertical bar pressure (pressure), and the impact of foundation settlement. The floor is mounted on the floor, although the floor is reinforced concrete (already hardened), but still to prevent the floor under the action of the deformation (vertical deflection) to produce stability problems.

- Q: How long does the width of the template support more than how much height the beam can not be poured at the same time?

- Height of more than 8m or span of more than 18m, the total load of more than 10kN / m2 or centralized line load greater than 15kN / m template support system and the use of beam plate at the same time pouring concrete construction method to immediately stop construction.

- Q: What is a template for pulling bolts

- To the stencil fixed, a two-headed round bar, insert the template, the two tied to the nut

- Q: Frame support system in the framework of the support system of wood support has been unable to withstand the pressure, the use of steel frame as a wooden mold support system, with steel pipe as a support system used in the bolt fasteners, etc., how much money Ton. How much is a fastener, the above is not used in the construction industry used in the external scaffolding, stressed! The Is the kind of support system as a wood template! Please give the professionals a detailed answer! There is the price, that place to sell? The

- Tube is tons of billing, because the wall thickness is different so the price is different, it should be about 6000 it, of course, the pipe is good or bad, the price is different. Bolt site are called fasteners, fasteners, of course, there are weight of the small 1.4 pounds of the general also 1.7 pounds, it should be about 4.0 it

- Q: 400 thick concrete roof template support system need expert demonstration?

- No need. Because 400mm thick is very common, the saying goes to stand the top of the jack - are now steel pipe stent, generally do not support the phenomenon can not afford

Send your message to us

H20 Timber beam formwork with single side bracket

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches