Geogrid Stiffness

Geogrid Stiffness Related Searches

Geogrid Strength Geogrid Stabilization Geogrid Ground Stabilisation Geogrid Pullout Resistance Geogrid Slope Stabilization Geogrid Tensile Strength Pullout Resistance Of Geogrid Tensile Strength Of Geogrid Geogrid Subgrade Stabilization Base Stabilization Geogrid Geogrid For Soil Stabilization Geogrid Retaining Walls Geogrid For Road Stabilization Retaining Wall Geogrid Geogrid Placement Geogrid Pavement Reinforcement Geogrid In Retaining Walls Geogrid Base Reinforcement Geogrid Properties Geogrid Construction Geogrid For Steep Slopes Geogrid Comparison Geogrid Reinforced Foundation Slope Reinforcement Geogrid Geogrid Machine Geogrid Pavement Structural Geogrid Laying Geogrid Geogrid Reinforcing Fabric Geogrid Reinforced SoilGeogrid Stiffness Supplier & Manufacturer from China

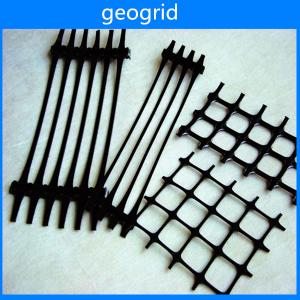

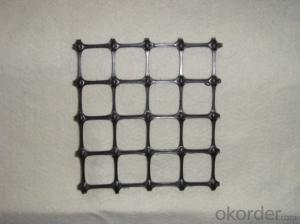

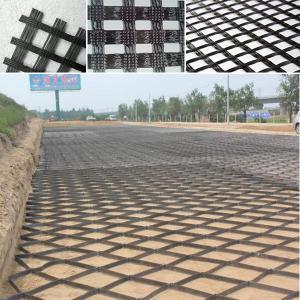

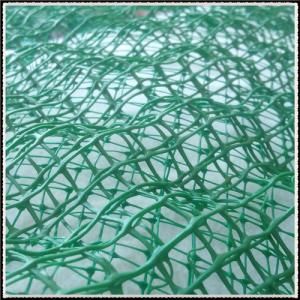

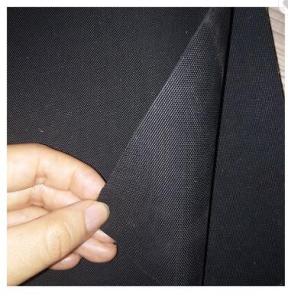

Geogrid Stiffness is a type of geosynthetic material designed to enhance the stability and load-bearing capacity of soil structures. It is widely used in civil engineering projects such as road construction, slope reinforcement, and retaining walls. The product is engineered with a high level of stiffness, which allows it to effectively distribute loads and prevent soil movement.Geogrid Stiffness is applied in various scenarios where soil reinforcement is necessary. It is commonly used in the construction of roads and highways, where it helps to increase the load-bearing capacity of the subgrade, reducing the risk of rutting and deformation. In addition, it is utilized in slope stabilization projects to prevent soil erosion and landslides, as well as in the construction of retaining walls to provide additional support and stability. The product's versatility and effectiveness make it an essential component in many civil engineering applications.

Okorder.com is a leading wholesale supplier of Geogrid Stiffness, offering a vast inventory of this high-quality product. With a commitment to customer satisfaction and a focus on providing reliable and durable materials, Okorder.com ensures that customers receive the best possible Geogrid Stiffness for their specific needs.

Hot Products