Geogrid Pullout Resistance

Geogrid Pullout Resistance Related Searches

Pullout Resistance Of Geogrid Geogrid Strength Geogrid Stiffness Geogrid Tensile Strength Geogrid Retaining Walls Geogrid Stabilization Tensile Strength Of Geogrid Geogrid Base Reinforcement Geogrid Erosion Control Geogrid Ground Stabilisation Geogrid Slope Stabilization Geogrid Pavement Reinforcement Geogrid Reinforced Slope Erosion Control Geogrid Retaining Wall Geogrid Slope Reinforcement Geogrid Geogrid Asphalt Reinforcement Geogrid Walls Geogrid In Retaining Walls Geogrid Reinforcing Fabric Geogrid Reinforced Soil Geogrid-Reinforced-Soil Extruded Geogrid Geogrid Placement Geogrid Construction Geogrid Wall Construction Geogrid Reinforced Earth Wall Tensar Geogrid Reinforcement Geogrid Reinforced Foundation Geogrid Subgrade StabilizationGeogrid Pullout Resistance Supplier & Manufacturer from China

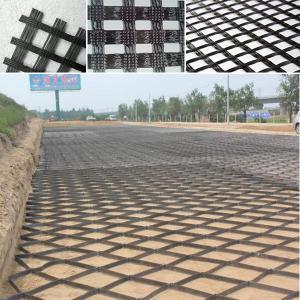

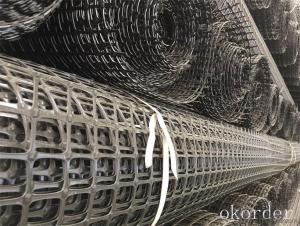

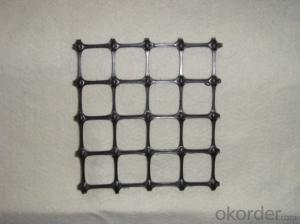

Geogrid Pullout Resistance is a type of geosynthetic material designed to enhance the stability and load-bearing capacity of soil structures. It is engineered to provide reinforcement by increasing the soil's tensile strength and preventing soil movement, making it an essential component in various civil engineering projects.The Geogrid Pullout Resistance product is widely used in applications such as road construction, slope stabilization, and retaining wall reinforcement. It is particularly effective in situations where soil conditions are poor or where increased load-bearing capacity is required. By incorporating Geogrid Pullout Resistance into these projects, engineers can ensure that the structures are more stable, durable, and resistant to deformation under various environmental conditions.

Okorder.com is a leading wholesale supplier of Geogrid Pullout Resistance, offering a vast inventory of this essential geosynthetic material. With a commitment to quality and customer satisfaction, Okorder.com ensures that each order of Geogrid Pullout Resistance is of the highest standard, providing customers with a reliable and cost-effective solution for their construction and engineering needs.

Hot Products