Fiberglass Geogrids in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction

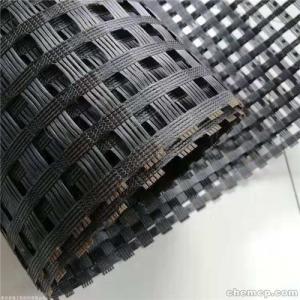

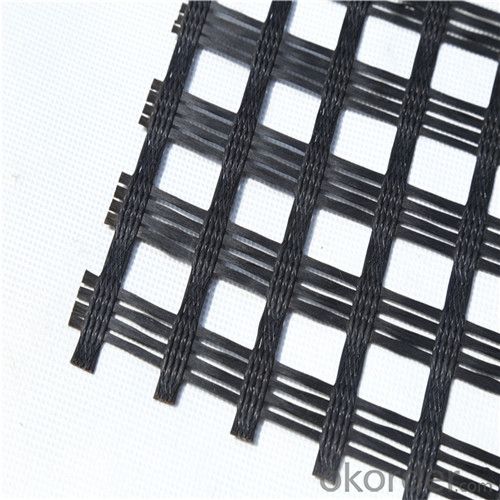

Geogrids form a distinct category of geosynthetics designed for reinforcement. These products are characterized by a relatively high tensile strength and a uniformly distributed array of large apertures (openings between the longitudinal and transverse elements). The apertures allow soil particles on either side of the installed sheet to come into direct contact, thereby increasing the interaction between the geogrid, aggregate and some soils. Also, the apertures ensure vertical drainage of a reinforced free-draining aggregate/soil.

The geogrid elements vary in polymer type and cross-sectional dimensions. They can sometimes change shape and dimensions within their length. Geogrids are either integrally manufactured (punched and drawn sheets; or extruded), ultrasonically or adhesive bonded strips, or joined in a knitting or weaving process and then coated. Polymer types include polyethylene, polypropylene or high tenacity polyester that has been coated.

Although geogrids are used primarily for reinforcement, some products are designed for asphalt overlay and waterproofing or for separation and stabilization. Geogrids also are used as gabions and sheet anchors, inserted between geotextiles and geomembranes, or used to construct mattresses for fills or embankments over soft soils.Woven Geogrids are flat structures in the shape of a net made of high module synthetic fibres, that may also be coated with a further protection layer, using synthetic material (usually PVC or other polymer).

Geogrid application filled with ground material is one of the easy of soil reinforcement. The thickness of such construction may be 50% less than the thickness of standard replacement which allows avoiding costly soil replacement.

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: What is the action mechanism of OKorder geogrid

- Glass fiber geogrid / glassgrid mechanism of reflective cracking is due to the old concrete surface layer in the vicinity of the joint or crack of large displacement caused by the asphalt overlay above appear stress concentration caused by the. Glass fiber geogrid has been developed rapidly in recent years, and is widely used in asphalt pavement, especially used in asphalt overlay to reduce reflection cracks. Texas Traffic College of AM University in Canada with its unique overlay tester of glass fiber geogrid reinforced cover did a lot of tests and experiments show that the reinforced asphalt specimen cracking resistance than the unreinforced specimens two times. Wollongong Municipal Bureau of New South Wales, Australia has conducted on-site tests of glass fiber geogrid, PP geogrid, geotextile and thickness of asphalt concrete surface layer of reflection crack control products, the conclusion is glass fiber geogrid laying convenience, control effect of reflection crack is the most significant, and the cost is moderate. Therefore we should promote the application. Due to the reinforcement effect of glass fiber geogrid on asphalt overlay, so it can be in the premise of effective control of reflection cracks, reduce the asphalt overlay thickness (with and without laying fiberglass geogrid, compared) reduce the cost, and achieved good economic benefit.

- Q: Geogrid TX160 what does that mean?

- The geogrid is made of polypropylene, polyvinyl chloride and other high molecular weight polymers by hot pressing or molding

- Q: What is the recommended geogrid aperture shape for specific applications?

- The recommended geogrid aperture shape for specific applications varies depending on the specific requirements of the project. However, commonly used shapes include square, rectangular, and hexagonal apertures. These shapes provide different levels of stability, soil confinement, and load distribution, allowing engineers to select the most suitable option based on factors such as soil type, slope angle, and anticipated loads.

- Q: Basic introduction of fiberglass geogrid

- Glass fiber geogrid is a kind of new type of excellent soil base to enhance the pavement and subgrade. Fiberglass geogrid has the characteristics of high tensile strength, low elongation, high elastic modulus, high and low temperature resistance,

- Q: Can geogrids be used in retaining walls for commercial developments?

- Yes, geogrids can be used in retaining walls for commercial developments. Geogrids are commonly employed as soil reinforcement materials in retaining wall construction. They provide stability and strength to the structure by distributing and confining the forces exerted by the retained soil. Their use in commercial developments ensures a reliable and long-lasting retaining wall system.

- Q: What is the effect of creep rupture on geogrid performance?

- The effect of creep rupture on geogrid performance is detrimental as it leads to a significant decrease in the geogrid's strength and stability over time. Creep rupture refers to the gradual elongation or deformation of a material under constant load, which can eventually result in the geogrid failing and losing its ability to provide reinforcement or confinement. This can compromise the overall integrity and effectiveness of the geogrid in various civil engineering applications, such as soil stabilization, slope reinforcement, or retaining wall construction. Therefore, managing and minimizing creep rupture is crucial to maintaining the long-term performance and durability of geogrids.

- Q: Are geogrids resistant to biological clogging?

- Yes, geogrids are resistant to biological clogging. They are typically made from materials such as high-density polyethylene (HDPE) or polyester which are resistant to biological degradation. Additionally, geogrids have an open structure that allows for effective drainage and prevents the accumulation of organic matter that could lead to clogging.

- Q: Can geogrids be used in reinforcement of pavement overlays?

- Yes, geogrids can be used in the reinforcement of pavement overlays. Geogrids are commonly used to improve the structural integrity and durability of pavement overlays by distributing load, reducing cracking, and enhancing overall performance.

- Q: Geogrid tgsg50-50 what does it mean

- That is, pull, 45KN, I am a manufacturer, geogrid TGSG45-45, two-way plastic geogrid 45KN, I hope to help you.

- Q: What are the benefits of using geogrids in construction projects?

- Geogrids offer several benefits in construction projects. Firstly, they provide reinforcement to soil, preventing its movement and improving stability. Secondly, they enhance the load-bearing capacity of the soil, allowing for the construction of structures on weak or unstable ground. Additionally, geogrids help reduce construction costs by eliminating the need for extensive excavation and the use of traditional construction materials. They also facilitate faster construction by reducing the time required for ground preparation. Overall, geogrids enhance the longevity and durability of construction projects while providing cost and time savings.

Send your message to us

Fiberglass Geogrids in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords