High Tensile Strength Polypropylene Geogrids for Road Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

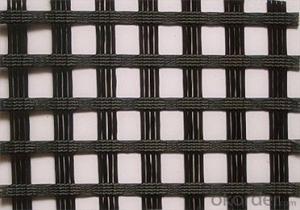

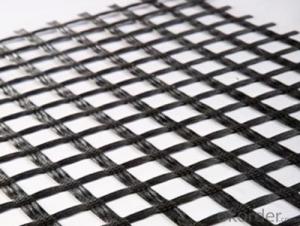

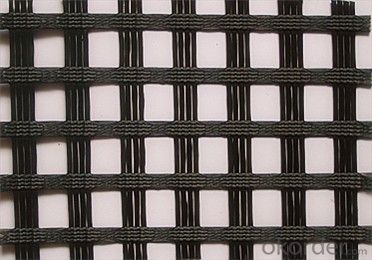

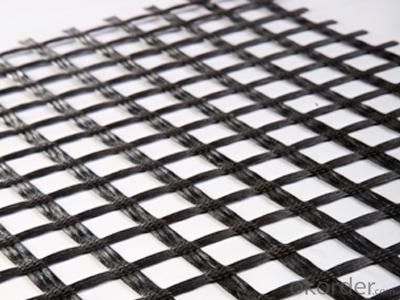

Structure of High Tensile Strength Polyester Geogrid:

High Tensile Strength Polyester Geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance.

Main Features of High Tensile Strength Polyester Geogrid:

fiberglass geogrid for soil reinforcement

fiberglass geogrid

Working & load transfer platforms

High tensile strength, low elongation

High stability

High Tensile Strength Polyester Geogrid Images

High Tensile Strength Polyester Geogrid Specification

Polyester Geogrid GGF80 Technical Specification | |||

Property | Test Method | Unit | Index |

Wide Width Tensile Strength | |||

MD | KN/M | ≥80 | |

CMD | KN/M | ≥80 | |

Elongation At Break | ≤4 | ||

Grid | MM | 25.4×25.4 | |

Width | M | 1~6 | |

Packaging | Details | ||

Roll Dimensions(W×L) | According to customer requirements | ||

Square Meters Per Roll | |||

Estimated Roll Weight | |||

It is widely used in Asphalt wall, railway foundation, dike slope, runway and sand harnessing.

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Can geogrids be used in reinforcement of soft ground?

- Yes, geogrids can be used in the reinforcement of soft ground. Geogrids are commonly used to improve the stability and load-bearing capacity of weak or soft soil by distributing the applied loads and reducing settlement. They are effective in reinforcing soft ground and can provide increased strength and stability to the soil, making them a suitable solution for various civil engineering and construction projects.

- Q: How do geogrids help in reducing the risk of soil erosion?

- Geogrids help in reducing the risk of soil erosion by providing reinforcement to the soil, increasing its stability and resistance to erosion. They are typically made of strong materials, such as plastic or polymer, and are installed beneath the topsoil or within the soil layers. Geogrids act as a barrier, distributing the load and reducing the pressure on the soil. This prevents soil particles from being washed away by water or wind, thus minimizing erosion and preserving the integrity of the landscape.

- Q: How much is the tensile strength of Geogrid

- Warp knitting: 15KN--200KN, the highest foreign to 400KN.

- Q: How do geogrids affect soil compaction?

- Geogrids can improve soil compaction by enhancing the load-bearing capacity of the soil. They act as a reinforcement layer, distributing the applied loads more evenly, reducing soil movement, and preventing excessive settlement. This helps to maintain a more uniform and stable soil structure, increasing its compaction and overall strength.

- Q: What is the difference between Geogrid and geogrid

- A series of three dimensional mesh or a three-dimensional grid screen with a certain height, which is made of thermoplastic polymers, such as vinyl chloride, is used as a civil engineering. Engineering applications: highway, railway, bridge, road, pier, dam, slag field, such as soft soil foundation reinforcement, retaining wall and pavement crack resistance engineering and other fields. Glass fiber mesh used in exterior wall, interior wall paint, mainly to prevent cracking, different materials at the junction of mortar plastering material hollowing. Local node reinforcement will also be used

- Q: Can geogrids be used in ground stabilization for pipelines?

- Yes, geogrids can be used in ground stabilization for pipelines. Geogrids are commonly used in civil engineering projects, including pipeline construction, to reinforce and stabilize the soil. They provide additional strength and stability to the ground, reducing the risk of ground movement and potential damage to the pipelines.

- Q: Bidirectional geogrid 5 meters long side, short side of the 3 meters

- Including plastic grille, fiberglass grille, steel grille, polyester grille, etc..

- Q: How do geogrids enhance the performance of geotextiles?

- Geogrids enhance the performance of geotextiles by providing mechanical reinforcement and increasing the tensile strength of the soil. They help to stabilize the soil, prevent lateral movement, and distribute loads more evenly, thereby improving the overall performance and durability of geotextiles in various civil engineering applications.

- Q: How do geogrids enhance the performance of geosynthetic clay liner drainage systems?

- Geogrids enhance the performance of geosynthetic clay liner drainage systems by providing additional reinforcement and stability to the clay liner. They prevent the clay liner from being displaced or deformed under heavy loads or high water pressures, thereby improving its overall effectiveness in controlling water flow.

- Q: What are some common standards and specifications for geogrids?

- Some common standards and specifications for geogrids include ASTM D6637 (Standard Test Method for Determining Tensile Properties of Geogrids by the Single or Multi-Rib Tensile Method), ASTM D5262 (Standard Test Method for Evaluating the Unconfined Tension Creep and Creep Rupture Behavior of Geosynthetics), and ISO 10318 (Geosynthetics - Wide-width tensile test). These standards provide guidelines for testing and measuring the tensile strength, creep behavior, and other mechanical properties of geogrids.

Send your message to us

High Tensile Strength Polypropylene Geogrids for Road Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords