Geomembrana 0.8-3 mm of New HDPE For Highway

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geomembrana 0.5-2.5 mm of New HDPE Made in China

Description Of Geomembrana 0.5-2.5 mm of New HDPE Made in China

The plastic film is used as the material of the plastic film as the anti - material, and the material of the non - woven fabric is made from the non - woven fabric. Its anti - permeability performance depends mainly on the anti - leakage performance of plastic film. At present, the domestic and international impermeable plastic film, mainly (PVC) and polyethylene (PE), EVA (ethylene / vinyl acetate copolymer), the tunnel application is also designed to use ECB (ethylene vinyl acetate modified asphalt blend membrane), they are a kind of high molecular weight chemical flexible material, the proportion is small, the extension is strong, the ability to adapt to deformation, corrosion resistance, low temperature resistance, frost resistance.

Main Features of Geomembrana 0.5-2.5 mm of New HDPE Made in China

Polyethylene (PE) geomembrane is divided into low-density polyethylene (LDPE) geomembrane

Applications of Geomembrana 0.5-2.5 mm of New HDPE Made in China

Low density polyethylene geomembrane for transport facilities

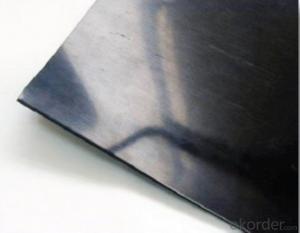

IMages of Geomembrana 0.5-2.5 mm of New HDPE Made in China

FAQ:

1. What are we supplying?

We are specialized in producing .geotextile , geocell, geogrid, geomembrane

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q:How about sticking membrane on the window?

- It is very good. The styles of the membrane are various, enough for you to choose the one you like. It is general to use the frosted membrane in bathroom. The advantages of this membrane is that it can ensure the privacy of the room with higher heat insulation and convenience in the field of cleaning than curtain. It can let more light into the room than curtain. So there is no need to worry about the issue of daylighting.

- Q:What are the design considerations for geomembrane installations?

- Some of the key design considerations for geomembrane installations include selecting the appropriate material, considering the site conditions and environmental factors, ensuring proper slope and anchoring, evaluating the durability and longevity of the geomembrane, and incorporating a proper drainage system. Additionally, the design should also account for any potential stress factors, such as chemical exposure or temperature fluctuations, and provide for regular inspection and maintenance.

- Q:What are the fire resistance properties of geomembranes?

- Geomembranes typically have excellent fire resistance properties. They are generally made from materials such as high-density polyethylene (HDPE) or polyvinyl chloride (PVC) which have inherent flame-retardant properties. These materials have high melting points and low flammability, making them resistant to ignition and minimizing the spread of fire. Additionally, geomembranes can be manufactured with additives that further enhance their fire resistance. Overall, geomembranes are considered a safe and reliable option for fire containment and prevention in various applications.

- Q:Can geomembranes be used in floating covers?

- Yes, geomembranes can be used in floating covers. Geomembranes are impermeable liners that are commonly used in various applications, including floating covers. Floating covers are used to prevent evaporation, control odors, and protect the contents of ponds, lagoons, or tanks. The geomembrane acts as a barrier between the water or liquid and the atmosphere, effectively sealing the cover and preventing any leakage or contamination.

- Q:Where are construction geomembrane in ash dam?

- Geomembrane and other geotechnical materials are fixed with anchoring ditch in the middle of side slope. There are construction team and welding equipments.

- Q:how is the effect decoration color film.

- Its bright colors, make the home brighter, it also uses the European Polymer Display technology, refractive effect dazzling eye-catching, all-encompassing design, according to the consumer to customize the overall style decoration pattern style, fashion, home, new feeling, appear instantly. In addition, it has the following advantages: ordinary glass crystal color film will become a safe explosion-proof, UV, heat insulation sunscreen, beautiful decoration and many other safety features insulation sunscreen glass; interior walls, baffles and glass paste crystal color film, reduce and absorb noise ; wear-resistant surface layer can effectively prevent external damage, scratch, wear and toughness. Good temperature resistance, has a certain insulation effect, fire retardant.

- Q:what's the difference between nanometer mobile phone stick membrane and steel glass membrane ?

- 1.tempered glass it has the advantages of high-strength scratch-resistant. falling broken-resistant, ultrathin. and almost having no feeling when pasting on the phone . Glass surface has had special treatment, feel more smooth, and the operation is more fluent. Safety. Simple to install the glass membrane using electrostatic bonding mode, anyone can easily install, and it will not produce bubbles. Recycled, it can be reused for many times, and it will not leave marks on your phone. Screen transmittance is up to 98%. it can prevent the electron wave effects on human health. It does not affect the mobile phone sets and other mobile phone parts. 2.nanometer-glass membrane has the technology of AGC glass reinforced HARVES nanometer technology through international HARVES nano-coating technology, using high-density nanoscale hydrophobic oleophobic coating and it can obtain ultra-lubricating function, so that the fingerprint traces of oil can not be left in the stick membrane surface, and it can reach the anti-fingerprint oil pollution-resistant effect. in the long term, it can effectively prevent stick membrane scratches, and has a high light transmittance. Ultra lubrication, making fingerprint traces of oil not be left in the stick membrane surface, and having the anti-fingerprint anti-oil pollution effect. 4. AG glass Ultra-high transmittance glass plus HARVES nano-coating to improve the level of the transmitted light, the ultimate 94% transmittance, restore true color screen, greatly enhancing the definition of the screen, give the user a high-definition visual experience. Anti cracking technology MAS glass film contains special rubber material, after tempering treatment, it uses more security. the function of auto attachment

- Q:What is the role of geomembranes in industrial wastewater treatment?

- Geomembranes play a crucial role in industrial wastewater treatment by acting as a barrier to prevent the leakage or contamination of wastewater. They are used to line containment ponds, storage tanks, and other structures to effectively contain and manage the wastewater, ensuring it does not seep into the surrounding soil or groundwater. Additionally, geomembranes can also be used in the construction of wastewater treatment plants to separate different treatment stages and prevent the mixing of different types of wastewater. Overall, geomembranes provide an essential protective layer in industrial wastewater treatment infrastructure, helping to safeguard the environment and human health.

- Q:Can geomembranes be used in decorative pond installations?

- Yes, geomembranes can be used in decorative pond installations. They are often used as a flexible and durable lining material to prevent water leakage and provide a smooth surface for pond features such as waterfalls, fountains, and rock formations.

- Q:how to use wallpaper basilemma

- there are several steps to use wallpaper basilemma: 1, the wall should be smooth and dry. 2, the cement wall should be made in level by the putty powder. 3, the wall leved by the talcum powder, due to the smooth wall surface and the unstable powder, it usually pastes the wallpaper after the sanding. 4, all the wall surface pasted the wallpaper (cement walls, plaster walls, wood filler-dimensional board, block board, etc.) must first mold wall good, after it drying, brushing the wallpaper basement membrane again, and after it drying, it is good to paste wallpaper. (When attached to the basilemma no hand stickiness is appropriate)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Geomembrana 0.8-3 mm of New HDPE For Highway

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords