Reinforced Polypropylene Geomembrane - 0.15-3mm HDPE/LDPE Geomembrane Price for Liner Piscine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geomembrane Introduction:

HDPE Smooth Face geomembrane are the preferred products for lining projects requiring

low permeability , corrosion protection , exceptional chemical and ultraviolet resistance properties ,

which makes them extremely cost-effective for many applications such as waste landfill ,

storage reservoirs ,canals , powr plants in energy , vapor barriers , and waste water treatment

in the line of industry and aquaculture and agriculture projects.

Geomembrane Specification:

Thickness | 0.12mm-4.0mm |

Length | 50m/roll,100m/roll,150m/roll or as your choice |

Width | 5.0m-7.0m or as your choice |

Color | White/Black/Blue/Green,mainly black |

Material | HDPE |

Delivery port | Qingdao |

Package: | woven bag or as customers' requests |

Product time | 2-20 days |

Features | 1.Good physical and mechanic performance |

2.High tearing resistance, strong deformation adaptability | |

3.Puncture-resisting, aging resisting, ultra-violet radiation, oil and salt, and corrosion resistance | |

4.Good adaptability to high and low temperature, non-toxicity, long service life | |

5.Good waterproof, drainage, anti-seepage and damp proof effects | |

6.Complete width and thickness specifications, low cost and easy installation. | |

Note | We can do as your demand,please feel free to contact us for more information |

Geomembrane Usage:

1.landfill,sewage or control the waste residue seashores seepage.

2.Lake dam,tailings dams,sewage dam and reservoir,channel,storage of liquid pools(pit,ore)

3.The subway ,tunnel,anti-seepage lining of basement and tunnel.

4.To control the roadbed and other foundation saline seepage.

5.Dike,the front of the sam foundation seepage prevention bedding,level of vertical impervious layer , construction cofferdam,waste field.

6.Seawater,freshwater fish farms.

7.Highway,the foundations of the highway and railway;the expansive soil and collapsible loess of the waterproof layer.

8.Anti-seepage of roofing

HDPE geomembrane liner technical of ASTM test GM 13 standard:

No. | Item | Test Value | |||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 1.8mm | 2.0mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.94 | |||||||

2 | Strength at yield,N/mm | 11 | 15 | 18 | 23 | 27 | 30 | 38 | 45 |

3 | Strength at break ,N/mm | 21 | 28 | 33 | 43 | 51 | 57 | 71 | 85 |

4 | Elongation at yield,% | 13 | |||||||

5 | Elongation at break,% | 700min | |||||||

6 | Tear Resistance N | 93 | 125 | 156 | 187 | 219 | 249 | 311 | 373 |

7 | Puncture Resistance N | 263 | 352 | 440 | 530 | 618 | 703 | 881 | 1059 |

8 | Stress Crack Resistance, hrs | 400 | |||||||

9 | Carbon Black Content, % | 2.0-3.0 | |||||||

Carbon Black Dispersion | 1 or 2 | ||||||||

10 | Standard OTI Min | 100 | |||||||

High Pressure OTI Min | 400 | ||||||||

11 | Impact Cold Crack at -70°C | Pass | |||||||

12 | Water vapor permeability (gNaN/cm2 .s.Pa) | ≤1.0×10-13 | |||||||

13 | Dimensional Stability (%) | ±2 | |||||||

FAQ:

- Q1: Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

HDPE Geomembrane Price

- Q2: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

- Q3:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

- Q4:What is your delivery time?

A:Production time usually costs 2-20 days.

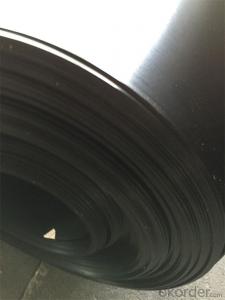

Gemembrane Show:

- Q: What are the considerations for geomembrane installations in seismic zones?

- When installing geomembranes in seismic zones, several considerations need to be taken into account. Firstly, the geomembrane material should have adequate tensile strength and flexibility to withstand the ground movement caused by earthquakes. It is essential to choose a geomembrane that can elongate and deform without rupturing or tearing under seismic activity. Additionally, the anchorage and attachment of the geomembrane to the underlying subgrade should be carefully designed. Proper anchoring techniques, such as using tensioning devices or anchor trenches, must be employed to prevent the geomembrane from shifting or uplifting during seismic events. The geomembrane should also be securely fastened to any adjacent structures or containment systems to avoid potential damage or leakage. Furthermore, the design of the subgrade beneath the geomembrane should consider the seismic forces and soil liquefaction potential. Adequate soil compaction, reinforcement, and drainage measures should be implemented to ensure stability and prevent soil liquefaction, which can lead to ground failure and damage to the geomembrane. Regular inspections, maintenance, and repairs should be conducted to identify any potential damage or degradation of the geomembrane caused by seismic events. Early detection and timely repair can help prevent further deterioration and maintain the integrity of the geomembrane system in seismic zones.

- Q: What are the limitations of geomembranes in seismic-prone areas?

- Geomembranes, although widely used as a barrier system in various applications, have certain limitations in seismic-prone areas. One significant limitation is their potential vulnerability to damage or puncture during seismic events. The intense ground shaking can lead to ground displacement, settlement, and surface rupture, which may cause the geomembranes to tear or rupture, compromising their effectiveness as a containment or lining system. Additionally, the potential for liquefaction, landslides, or soil liquefaction in seismic-prone areas can also pose challenges for the stability and integrity of geomembranes. Therefore, careful design considerations, such as incorporating additional reinforcement layers or selecting more robust materials, are necessary to mitigate these limitations and ensure the effectiveness and reliability of geomembranes in seismic-prone areas.

- Q: Geomembrane seams inspection should use aerate inspection method, what's the length that inspection demands? is there any national standard?

- it's regarded as qualified connection, such as the gas inside the seams leaks along with the gas needle, when examined with microscope ; detecting distance of each section should be about 1.0m, clamping the gas needle, input the air, if there are bubble leaks but without gas leaking, 5m-3, you can use welding gun or adhesive to deal. 5-2Mpa, you can use figer to press gas needle and see whether two seams are flat. 2, the pressure on the testing procedures of geosynthetics should be controled in 0. while pumping, "geosynthetics technical specifications" GB50290-98 geomembrane seam site, there is currently no good methods & # 57350, then a pump with a pressure gage, and a melting point or seams foam edge, etc. time is in about 30s, the gas needle wil pass through a hole between the seams. & # 57350, dotted, after observing more than 30 seconds, put the microscope on the suspicious place; mostly visual & # 57350 under normal circumstances, welding two seams between the torch with welding gun. 1, no wrinkle, no slag, transparent, plug the needle hole with plasticine.

- Q: How to remove the mobile phone film?

- Removal method: Only need to take an ordinary eraser on the mobile phone screen gently wipe back and forth, you can easily remove the offset, but the key point is, do not leave any damage, the screen is still bright. Method to offset eraser is also applicable to some smooth surfaces, such as glass, bathroom wall etc..

- Q: Can geomembranes be customized for specific projects?

- Yes, geomembranes can be customized for specific projects. They can be tailored to fit the size, shape, and specific requirements of a project, ensuring optimal performance and efficiency. Customization options include material selection, thickness, color, texture, and the inclusion of additives or reinforcements.

- Q: How do geomembranes provide water retention in green roof systems?

- Geomembranes provide water retention in green roof systems by acting as a barrier that prevents water from draining off the roof surface. The impermeable nature of geomembranes helps to hold and store water within the green roof system, allowing plants to access it for nourishment and reducing the need for additional irrigation.

- Q: What are the requirements for geomembranes used in potable water applications?

- The requirements for geomembranes used in potable water applications include being made from materials that are certified safe for contact with drinking water, having a low permeability to prevent water leakage, being resistant to UV degradation to ensure long-term durability, and meeting specific standards for puncture resistance, tensile strength, and chemical resistance.

- Q: How long can glass sound insulation film be used?

- It can be used for four or five years without problem. If there is kid in the family, it may not be able to last for that long for the glass film scratches easily.

- Q: How to stick the film on lampblack machine?

- Now, I will explain to you how to stick the lampblack machine film in detail. 1, You can just stick the preservative film on all places which the film can be stuck on without affecting the operation of the smoke exhaust ventilator like its top and side walls when you has just bought it. 2, If it gets dirty, you can just replace it with a new one.

- Q: What are the quality control measures for geomembrane installations?

- Quality control measures for geomembrane installations include proper surface preparation, ensuring the geomembrane is installed without wrinkles or folds, using appropriate welding techniques to join geomembrane panels, conducting leak tests to ensure a watertight seal, and conducting regular inspections during and after installation to identify any potential defects or issues.

Send your message to us

Reinforced Polypropylene Geomembrane - 0.15-3mm HDPE/LDPE Geomembrane Price for Liner Piscine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords