ECB Geomembranes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ECB Geomembranes

Products Description

This product is extruded PE membrane formed by adding anti- oxidant, absorbent of ultraviolet and dyestuff into HDPE or LDPE or EVA and ECB will provide an effective barrier to of liquid water and water vapor.

Characteristics

·HDPE performs well in mechanical properties ,ageing-resistance , chemical-resistance ,climate- resistance and

resistance to puncture .

·LDPE & EVA feathers great elongation, good flexibility at low temperature, softness and easy

installation.

·ECB ,high-class waterproofing rolls, is formed by combining ethylene polymer with oil-resin.

Products Specification

Name | Thickness(mm) | Width(m) |

HDPE | 0.75-2.5 | 4-8 |

LDPE | 0.2-2.5 | 4-8 |

EVA | 0.2-2.5 | 2-8 |

ECB | 1.0-2.0 | 2-8 |

Features:

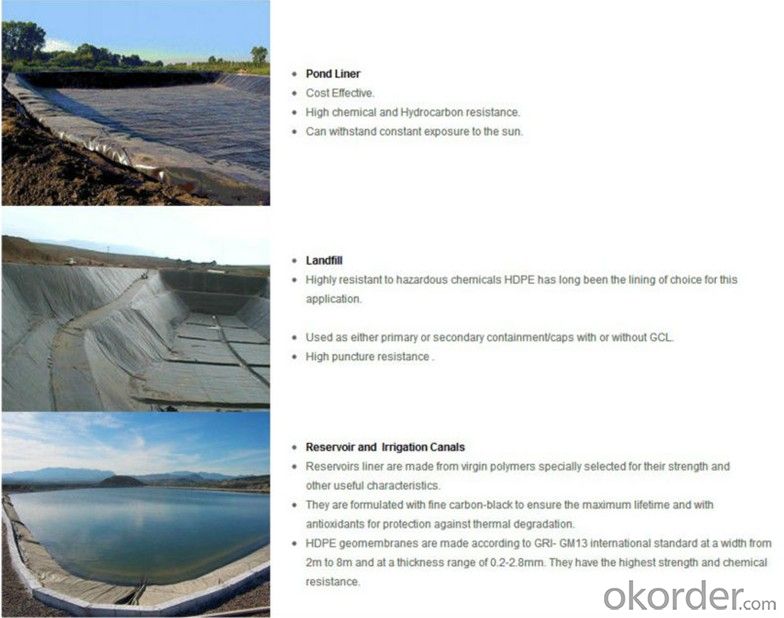

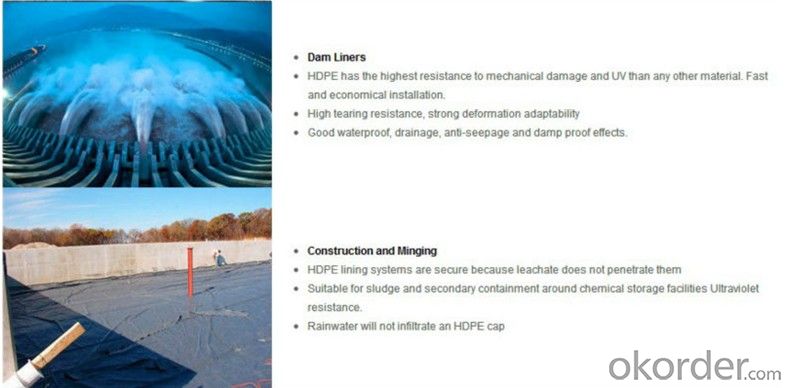

1.All physical factors such as anti-draw, anti-tear, and anti-stab meet the requirement of water works, chemicals, tunnels,

and transportation project in most conditions.

2.Good aging, durable performance, and wide temperature range, it can be useful over

thirty years on the condition of -60æ«60æ.

3.Anti-stab and fine friction factors.

4.Canker proof, acid and alkali proof, untoxic.

5.Lower cost per unit area, cost is 1/3«1/2 lower than that of PVC film, glass and cloth.

6.Convevient to install and dependable effect.

Application Rage

- Q: Are there any specific requirements for installing a waterproofing membrane?

- Yes, there are specific requirements for installing a waterproofing membrane. These requirements may vary depending on the type of membrane being used and the specific application. However, some general requirements include: 1. Surface Preparation: The surface where the membrane will be installed must be clean, dry, and free from any dust, debris, or contaminants. Any cracks or defects in the surface should be repaired prior to installation. 2. Adhesive or Bonding Agent: Depending on the type of membrane, an adhesive or bonding agent may be required to ensure proper adhesion to the substrate. This adhesive should be compatible with both the membrane and the substrate. 3. Primer: In some cases, a primer may be necessary to enhance the adhesion between the substrate and the membrane. The type of primer required will depend on the specific membrane and substrate being used. 4. Seam and Joint Preparation: Properly preparing seams and joints is crucial to ensure a watertight installation. This may involve using a specific sealant or tape to reinforce the seams and prevent water penetration. 5. Installation Techniques: The membrane should be installed according to the manufacturer's instructions and industry best practices. This may include using a specific method such as torching, hot air welding, or cold adhesive application. 6. Overlaps and Transitions: Properly overlapping the membrane sheets and ensuring smooth transitions between different areas is essential for a successful installation. This will help prevent water from seeping through gaps or weak points in the membrane. 7. Quality Control: Regular inspections and quality control measures should be implemented throughout the installation process to ensure that the membrane is being installed correctly and meets the required standards. It is important to consult the manufacturer's guidelines and specifications for the specific waterproofing membrane being used, as different membranes may have unique installation requirements. Additionally, local building codes and regulations should also be considered to ensure compliance and to meet any specific requirements in your area.

- Q: Can a waterproofing membrane be used on precast stainless steel surfaces?

- Yes, a waterproofing membrane can be used on precast stainless steel surfaces. The waterproofing membrane will provide an additional layer of protection against water penetration, ensuring the longevity and durability of the stainless steel surface.

- Q: Can a waterproofing membrane be used in conjunction with expansion joint systems?

- Yes, a waterproofing membrane can be used in conjunction with expansion joint systems. The membrane can be applied over the expansion joint system to provide an additional layer of protection against water penetration, ensuring the longevity and effectiveness of the joint system.

- Q: Can a waterproofing membrane be used in tunnels?

- Yes, a waterproofing membrane can be used in tunnels. Waterproofing membranes are commonly used in tunnel construction to prevent water infiltration and protect the tunnel structure from damage caused by moisture. These membranes are designed to provide a barrier against water, keeping the tunnel dry and secure.

- Q: Can a waterproofing membrane be used on tunnels with architectural features?

- Indeed, tunnels with architectural features can benefit from the application of a waterproofing membrane. Such membranes possess versatility, enabling their usage on different structures, including tunnels with architectural elements. Their primary purpose is to establish a protective barrier against water infiltration, consequently safeguarding the structure against moisture-related harm. Regardless of the tunnel's unique architectural components, such as curves, arches, or decorative embellishments, a tailored waterproofing membrane can be tailored and implemented to ensure optimal water resistance. Therefore, it is imperative to seek guidance from a proficient waterproofing specialist experienced in working with tunnels and architectural features. They will assist in determining the most suitable membrane system for the specific project prerequisites.

- Q: Are waterproofing membranes suitable for commercial applications?

- Yes, waterproofing membranes are suitable for commercial applications. Waterproofing membranes are specifically designed to protect buildings, structures, and surfaces from water infiltration, moisture damage, and other related problems. They are often used in various commercial applications such as roofs, basements, underground parking garages, and exterior walls. Commercial buildings are exposed to a wide range of weather conditions and water sources, including rain, snow, and groundwater. Waterproofing membranes provide a reliable barrier against water penetration, preventing costly water damage and ensuring the longevity of the building. Additionally, they can also act as a vapor barrier, preventing moisture buildup and condensation within the building envelope, which can lead to mold growth and structural deterioration. Waterproofing membranes are available in various materials, such as bitumen, modified bitumen, EPDM, PVC, and TPO. These materials offer different advantages and characteristics, allowing for flexibility in choosing the most suitable option for specific commercial applications. They can be applied as a liquid coating, sheets, or panels, providing versatility in installation methods to accommodate different building designs and requirements. Furthermore, waterproofing membranes can be customized to meet specific commercial needs, such as fire resistance, UV protection, and durability. This makes them effective in protecting commercial properties that may be subjected to heavy foot traffic, mechanical equipment, or other potential sources of damage. In summary, waterproofing membranes are a highly suitable solution for commercial applications. They offer reliable protection against water infiltration, moisture damage, and other related problems, ensuring the longevity and structural integrity of commercial buildings. Their versatility, customization options, and ability to withstand various weather conditions make them an excellent choice for commercial waterproofing needs.

- Q: Can waterproofing membranes be used on concrete countertops?

- Yes, waterproofing membranes can be used on concrete countertops. These membranes are designed to create a barrier that prevents water from seeping into the concrete, protecting it from damage and increasing its lifespan.

- Q: Can waterproofing membranes be used on concrete slabs?

- Yes, waterproofing membranes can be used on concrete slabs. These membranes are designed to provide a protective barrier against water infiltration and can effectively prevent moisture from seeping into the concrete.

- Q: Can waterproofing membranes be used on concrete floors?

- Yes, waterproofing membranes can be used on concrete floors. Waterproofing membranes are commonly used in construction to prevent water penetration and protect the underlying structure. When applied to concrete floors, these membranes create a barrier that prevents water from seeping through and causing damage. Waterproofing membranes can be particularly useful in areas such as basements, bathrooms, and outdoor patios where water exposure is common. They help to maintain the integrity of the concrete floor and protect it from moisture-related issues like cracking, spalling, and mold growth.

- Q: Can waterproofing membranes be used in wet areas like bathrooms?

- Waterproofing membranes are indeed suitable for wet areas such as bathrooms. It is strongly advised to utilize these membranes in bathroom spaces to prevent water damage and leaks. These membranes are specifically designed to form a barrier against moisture, guaranteeing that water does not infiltrate the bathroom's walls, floors, or other surfaces. By applying a waterproofing membrane, you can effectively safeguard the underlying structure from water damage, mold growth, and other issues caused by extended exposure to moisture. This is particularly crucial in wet areas like bathrooms where water is consistently present. Waterproofing membranes can be found in various forms, including sheet membranes, liquid membranes, and even pre-formed shower trays. They can be applied to walls, floors, shower enclosures, and other surfaces to create a tight seal against water. It is essential to correctly install and maintain the waterproofing membrane according to the manufacturer's guidelines to ensure its efficacy and durability. Therefore, if you are contemplating renovating or constructing a bathroom, it is highly recommended to use waterproofing membranes to guarantee a long-lasting and moisture-resistant space.

Send your message to us

ECB Geomembranes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords