Hot Rolled Square Steel Billet 3SP 5SP 20MnSi Using Good Quailty Ceramic Fiber Bulk /JH

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel in Hot Sale

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel

Specification (see below)

Standard: GB/JIS/ASTM

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Technique: Hot rolled

FOB Unit Ton Price $300-350 and Usually I will quote you CIF price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

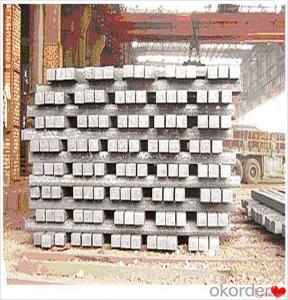

Product image:

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

- Q: What are the different types of steel wire and their uses?

- There are several types of steel wire, each with its own unique properties and uses. Some common types include carbon steel wire, stainless steel wire, galvanized steel wire, and spring steel wire. Carbon steel wire is widely used in construction, automotive, and manufacturing industries due to its high strength and durability. Stainless steel wire is corrosion-resistant and commonly used in applications requiring hygiene and strength, such as medical devices and kitchen utensils. Galvanized steel wire has a protective zinc coating and is often used in fencing and agricultural applications. Spring steel wire has excellent elasticity and is primarily used in springs and other mechanical components.

- Q: What are the different types of steel tanks and their applications in the pharmaceutical industry?

- There are several types of steel tanks used in the pharmaceutical industry. These include stainless steel tanks, carbon steel tanks, and alloy steel tanks. Stainless steel tanks are commonly used for storing and mixing pharmaceutical ingredients due to their corrosion resistance and ease of cleaning. Carbon steel tanks, on the other hand, are often used for bulk storage of pharmaceutical products. Alloy steel tanks are typically used for specialized applications that require high strength and resistance to extreme temperatures. Overall, steel tanks play a crucial role in maintaining the integrity and quality of pharmaceutical products throughout their production and storage processes.

- Q: What are the different types of steel angles and their applications in the construction of bridges?

- There are primarily three types of steel angles used in the construction of bridges: equal angles, unequal angles, and inverted angles. Equal angles have both sides of equal length and are commonly used as structural components in bridge piers and towers. They provide stability and support to the overall structure. Unequal angles have one side longer than the other, and they are often used in bridge trusses and beams. These angles help distribute the load and provide strength to the bridge. Inverted angles, also known as L-shaped angles, are used as stiffeners in various bridge components such as girders, columns, and beams. They help resist bending and provide additional strength to critical areas of the bridge. Overall, the different types of steel angles play a crucial role in the structural integrity and stability of bridges, ensuring their durability and ability to withstand heavy loads and environmental factors.

- Q: What are the different types of steel tanks and containers available?

- There are several types of steel tanks and containers available, including above-ground storage tanks, underground storage tanks, pressure vessels, intermediate bulk containers (IBCs), and shipping containers. Each type serves a specific purpose and is designed to meet different storage or transportation needs.

- Q: What are the different types of steel profiles and their applications?

- There are several different types of steel profiles, each with their own specific applications. Some common types include I-beams, which are used in construction for structural support; C-channels, which are often used in industrial applications for framing and support; angle profiles, which are used for corner reinforcement and bracing; and flat bars, which are commonly used in manufacturing and construction for support and framing. Other types of steel profiles include round bars, square bars, and T-sections, each with their own unique applications in various industries.

- Q: How is steel rebar used in concrete construction?

- Steel rebar is used in concrete construction to provide reinforcement and strength to the concrete structures. It is typically placed within the concrete forms before pouring, forming a framework that helps to distribute the load and prevent cracking or failure. The rebar enhances the tensile strength of the concrete, allowing it to withstand greater forces and improve the overall durability and longevity of the structure.

- Q: How is steel used in the transportation industry?

- Steel is used extensively in the transportation industry due to its strength and durability. It is used in the construction of car frames, train tracks, and bridges, ensuring safety and stability. Additionally, steel is used in the manufacturing of ship hulls and aircraft structures, enabling them to withstand harsh environments and maintain their structural integrity.

- Q: What are the different types of steel forgings and their applications in the defense industry?

- There are three main types of steel forgings used in the defense industry: carbon steel forgings, alloy steel forgings, and stainless steel forgings. Carbon steel forgings are known for their strength and durability, making them suitable for various applications in defense, such as weapon components, tank tracks, and armor plating. Alloy steel forgings are made by adding various alloying elements to carbon steel, enhancing their strength, toughness, and resistance to wear and corrosion. These forgings are commonly used in critical defense components like aircraft landing gear, missile parts, and submarine propellers. Stainless steel forgings, on the other hand, are highly resistant to corrosion and have excellent mechanical properties. These forgings find applications in the defense industry, particularly in naval vessels, submarines, and aircraft carriers, where they are used for valves, pumps, shafts, and other critical components. Overall, steel forgings play a vital role in the defense industry by providing the required strength, durability, and performance needed for various defense applications, ensuring the safety and reliability of military equipment.

- Q: How do steel products contribute to the retail and commercial sector?

- Steel products contribute to the retail and commercial sector in various ways. Firstly, they are widely used in the construction industry for building structures, such as shopping malls, office buildings, and warehouses. Steel's strength, durability, and versatility make it a preferred choice for constructing large commercial spaces. Additionally, steel products are used to create shelving units, display racks, and storage systems in retail stores. These products provide a sturdy and reliable solution for organizing and displaying merchandise, ensuring efficient use of space and enhancing the overall shopping experience for customers. Moreover, steel is commonly used in the manufacturing of commercial equipment and fixtures, including cash registers, shopping carts, and display stands. These steel products offer durability and stability, ensuring the smooth operation of retail and commercial businesses. Furthermore, steel plays a vital role in the transportation and logistics sector. Steel containers, shipping pallets, and storage racks are essential in facilitating the movement and storage of goods in warehouses, distribution centers, and retail outlets. Overall, steel products are crucial for the retail and commercial sector as they provide the necessary infrastructure, equipment, and fixtures required for smooth and efficient operations, contributing to the growth and success of businesses in this sector.

- Q: What are the advantages of using steel bars in construction?

- There are several advantages of using steel bars in construction. Firstly, steel bars are incredibly strong and durable, providing structural integrity to buildings and ensuring they can withstand heavy loads and adverse weather conditions. Additionally, steel bars have a high tensile strength, allowing for longer spans and lighter structures, which can lead to cost savings in terms of materials and construction time. Moreover, steel bars are resistant to fire, corrosion, and pests, making them a reliable choice for long-term durability. Lastly, steel bars can be easily fabricated and customized to meet specific design requirements, offering flexibility and versatility in construction projects.

Send your message to us

Hot Rolled Square Steel Billet 3SP 5SP 20MnSi Using Good Quailty Ceramic Fiber Bulk /JH

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords