Converter Continuous Square Steel Billet 3SP 5SP 20MnSi Hot Selling

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

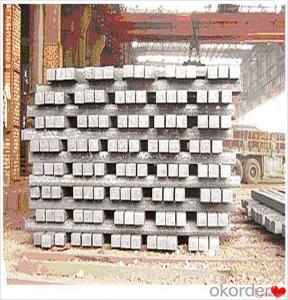

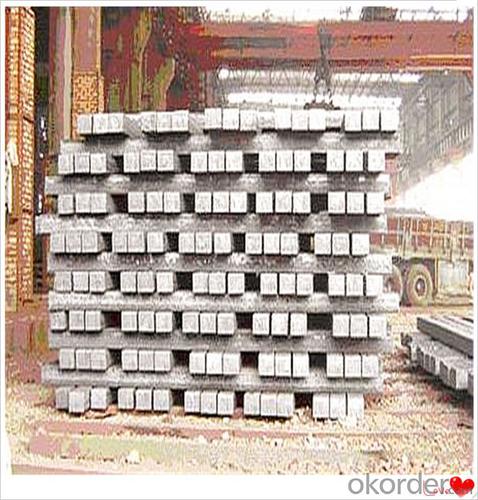

Converter Continuous Square Steel Billet 3SP 5SP 20MnSi Hot Selling

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

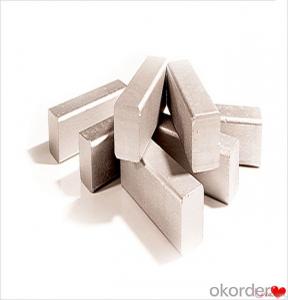

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: What are the different types of steel billet packaging materials?

- When selecting the suitable packaging material for steel billets, it is crucial to take into account the unique characteristics and benefits of the various options available in the market. The following are some commonly utilized packaging materials for steel billets: 1. Wooden Crates: Renowned for their durability and strength, wooden crates are a favored choice for packaging steel billets. They offer exceptional protection against external impacts and are particularly suitable for long-distance transportation. 2. Steel Strapping: Frequently employed to bundle steel billets together, steel strapping is a robust and secure packaging material. It boasts high tensile strength and resistance to breakage, ensuring that the billets remain intact during handling and transportation. 3. Plastic Wrapping: As a cost-effective and lightweight packaging option, plastic wrapping provides ample protection against moisture and dust, preventing any potential damage to the billets. Moreover, it is easily applicable and removable, rendering it a convenient choice for packaging. 4. Steel Framing: For larger and heavier steel billets, steel framing serves as a heavy-duty packaging material. It offers maximum protection and stability during transportation, effectively minimizing the risk of deformation or damage to the billets. 5. Cardboard Boxes: Smaller steel billets frequently find themselves packaged in cardboard boxes. These boxes are lightweight, easy to handle, and offer sufficient protection against minor impacts and scratches. Additionally, cardboard boxes can be customized in various sizes and shapes to accommodate different billet dimensions. 6. Stretch Film: Stretch film, a flexible packaging material, is commonly employed to wrap steel billets. It provides exceptional protection against moisture, dust, and scratches. Furthermore, stretch film imparts a certain level of stability to the billets, preventing any movement during transportation. When selecting the appropriate packaging material, it is crucial to consider the specific requirements of the steel billets, including size, weight, and transportation conditions.

- Q: How do steel billets contribute to the manufacturing of rail and transportation systems?

- Steel billets are an essential component in the manufacturing of rail and transportation systems. These billets serve as the raw material for the production of various components used in the construction of railways, such as rails, sleepers, and fasteners. One of the primary uses of steel billets in rail manufacturing is for the production of railway tracks. Steel billets are first heated and then rolled into long, slender sections called rails. These rails are then further processed and treated to withstand the heavy loads and constant wear and tear experienced in railway operations. The durability, strength, and resistance to deformation of steel make it an ideal material for railway tracks, ensuring safe and efficient transportation. Steel billets also play a vital role in the manufacturing of sleepers or railroad ties, which are used to support the rails and maintain their alignment. These sleepers, typically made from prestressed concrete or wood, require reinforcing bars made from steel billets to enhance their strength and structural integrity. Additionally, steel billets are used to produce fasteners, such as bolts, clips, and spikes, which are crucial for securely fastening rails to sleepers and maintaining track stability. Moreover, steel billets are used in the production of various transportation system components, including chassis, frames, and suspension systems for trains, trams, buses, and other vehicles. Their high strength and excellent formability make steel billets an ideal choice for these applications, as they can withstand the heavy loads and provide structural integrity necessary for safe and reliable transportation. In summary, steel billets play a significant role in the manufacturing of rail and transportation systems. From the production of railway tracks to the fabrication of sleepers, fasteners, and vehicle components, steel billets provide the necessary strength, durability, and structural integrity required for the efficient and safe operation of railways and transportation systems.

- Q: How are steel billets used in the production of railway components?

- Railway components rely heavily on steel billets during the production process. These billets, which are essentially semi-finished steel products, serve as the foundation for manufacturing various railway components such as rails, wheels, axles, and structural parts. To create railway components, steel billets are first heated to a specific temperature, enhancing their malleability. This crucial heating process enables easy shaping and forming of the steel into the desired component. Once the billets reach the required temperature, they proceed to the next stage of production. Here, they undergo processes like rolling, forging, and machining to transform them into the final shape and size needed for the specific railway component. For example, in the production of railway rails, heated steel billets pass through a series of rolling mills, gradually shaping and elongating them into the desired rail profile. Similarly, for wheels and axles, billets are forged and machined to achieve the necessary dimensions and surface finish. The utilization of steel billets ensures that the resulting railway components possess strength, durability, and the ability to withstand the heavy loads and stresses associated with railway operations. The quality and characteristics of the steel billets greatly influence the performance and lifespan of the railway components. In summary, steel billets play a critical role in producing railway components by providing the raw material that is shaped, formed, and processed into the essential final products for the safe and efficient operation of the railway system.

- Q: which companies are, and how the billet sales, how can we sell billet to ask for advice, thank you

- As for sales, one to information, two to high quality and low price, three to find relations.

- Q: What are the challenges faced in steel billet manufacturing?

- Steel billet manufacturing encounters various challenges. One of the primary obstacles is the attainment of consistent quality and uniformity in the billets. The billets must possess precise chemical composition and physical properties to meet the requirements of the end products. However, fluctuations in raw materials, like iron ore and scrap metal, can influence the billets' quality. Ensuring consistent quality throughout the production process is crucial but is difficult due to the variable nature of the raw materials. Another challenge lies in ensuring the appropriate heat treatment of the billets. Heat treatment is necessary to enhance the mechanical properties of the steel billets, but it demands precise control over temperature, time, and cooling rates. Any deviation from the recommended heat treatment process can lead to inconsistent mechanical properties, resulting in a decline in the overall billet quality. Furthermore, the production of steel billets involves intricate and energy-intensive processes. Manufacturing facilities must possess advanced equipment and technology to handle the high temperatures required for melting and casting the steel. The continuous casting process, commonly used for billet production, necessitates precise control over various parameters, such as casting speed and cooling rates. Maintaining the equipment and ensuring its proper functioning can be a challenge in itself. Moreover, environmental concerns present challenges in steel billet manufacturing. The process generates significant emissions of greenhouse gases, particulate matter, and other pollutants. Stricter environmental regulations and the need to reduce the carbon footprint of the manufacturing process require steel producers to invest in energy-efficient technologies and implement sustainable practices. Lastly, the market demand for steel billets can be volatile, posing challenges in production planning and inventory management. Demand fluctuations can result in overproduction or stockouts, impacting the overall efficiency and profitability of the manufacturing process. Overall, steel billet manufacturing encounters challenges related to maintaining consistent quality, achieving proper heat treatment, managing energy-intensive processes, addressing environmental concerns, and adapting to market dynamics. Overcoming these challenges necessitates continuous improvement, technological investments, and adherence to stringent quality standards.

- Q: How do steel billets contribute to the manufacturing of furniture?

- The manufacturing of furniture relies heavily on steel billets, which serve as the essential raw material needed to create strong and durable frames. These billets, produced through casting or hot rolling, are semi-finished steel products with a rectangular shape. After obtaining the steel billets, they can undergo various manufacturing techniques such as forging, extrusion, or machining to shape them into different furniture components. These components include frames for chairs, tables, beds, and other elements that require stability and strength. Using steel billets in furniture manufacturing offers several advantages. Firstly, steel is renowned for its exceptional strength and durability, making it an ideal material for furniture that can handle heavy loads and regular use. By utilizing steel billets, the furniture becomes robust and long-lasting, reducing the need for frequent replacements. In addition, steel billets provide design flexibility as they can be easily molded and shaped into different forms. This allows furniture manufacturers to create intricate and unique designs that meet customers' aesthetic preferences. Moreover, steel billets can be seamlessly welded, resulting in a more cohesive and visually appealing final product. Furthermore, steel is highly resistant to corrosion, which is crucial for furniture that may be exposed to moisture or environmental factors. By incorporating steel billets, the furniture remains free from corrosion, preserving its appearance and structural integrity over time. In conclusion, steel billets are indispensable in furniture manufacturing as they provide the necessary strength, durability, and flexibility to create sturdy frames and structural components. Their utilization enables furniture manufacturers to produce high-quality products that are long-lasting, visually appealing, and resistant to corrosion.

- Q: What are the main factors affecting the wear resistance of steel billets?

- The main factors affecting the wear resistance of steel billets can be categorized into several key aspects. First and foremost, the composition of the steel plays a crucial role. The presence of certain alloying elements, such as chromium, manganese, and molybdenum, significantly enhances the wear resistance of the steel. These elements form carbides and other compounds that create a hard and durable surface, capable of withstanding abrasive forces. Additionally, the microstructure of the steel is vital in determining its wear resistance. Fine-grained steels tend to have better wear resistance as the smaller grain size provides a more uniform and dense structure, reducing the likelihood of cracks and wear. Heat treatment processes, such as quenching and tempering, can be employed to further refine the microstructure and enhance the wear resistance. Surface finish is another vital factor influencing wear resistance. A smooth and well-polished surface reduces the friction between the steel billet and its surroundings, minimizing wear. Various machining techniques, such as grinding and polishing, can be employed to achieve the desired surface finish. Moreover, the hardness of the steel billet is a significant determinant of wear resistance. Hardness is typically measured using the Rockwell or Brinell scales, and higher hardness values generally indicate improved wear resistance. Heat treatment, alloying, and the addition of hardening agents can all contribute to increasing the hardness of the steel billet. Lastly, environmental factors also impact wear resistance. The presence of corrosive substances, high temperatures, or abrasive particles in the working environment can accelerate wear and reduce the lifespan of the steel billet. Employing appropriate coatings, such as chromium plating or thermal spraying, can mitigate these environmental effects and enhance wear resistance.

- Q: What are the main factors affecting the creep resistance of steel billets?

- The main factors affecting the creep resistance of steel billets include the composition of the steel, the temperature at which the billets are exposed, the applied stress, and the microstructure of the steel.

- Q: What are the different heat treatment processes applied to steel billets?

- There are several different heat treatment processes that can be applied to steel billets, depending on the desired properties and characteristics of the final product. Some of the most common heat treatment processes used for steel billets include: 1. Annealing: This process involves heating the steel billets to a high temperature and then slowly cooling them, usually in a controlled atmosphere or furnace. Annealing helps to relieve internal stresses, improve machinability, and enhance the steel's ductility and toughness. 2. Normalizing: Normalizing is a heat treatment process that involves heating the steel billets to a temperature above the critical range and then allowing them to cool in still air. This process helps to refine the grain structure, improve the mechanical properties, and enhance the machinability of the steel. 3. Quenching: Quenching is a rapid cooling process that involves immersing the steel billets in a quenching medium, such as water, oil, or polymer, after they have been heated to a high temperature. This process creates a hardened and stronger steel with improved wear resistance, but it may also result in increased brittleness. 4. Tempering: Tempering is a heat treatment process that follows quenching and involves reheating the hardened steel billets to a specific temperature and then cooling them in still air. This process helps to relieve residual stresses, reduce brittleness, and improve the toughness and ductility of the steel. 5. Austempering: Austempering is a heat treatment process that involves quenching the steel billets in a bath of molten salt or other medium at a temperature just above the critical range, followed by holding them at that temperature until the desired transformation occurs. Austempering produces a steel with high strength, improved ductility, and reduced distortion. 6. Martempering: Martempering is a quenching process similar to austempering, but with a shorter holding time at the quenching temperature. This process results in a steel with a combination of high strength and toughness, as well as reduced distortion. 7. Case hardening: Case hardening is a heat treatment process that involves adding carbon to the surface layer of the steel billets, typically through carburizing or nitriding. This process forms a hardened case with increased wear resistance, while maintaining a more ductile core. These are just a few examples of the heat treatment processes that can be applied to steel billets. The specific process used will depend on the desired properties of the final product and the type of steel being treated.

- Q: How do steel billets contribute to the overall aesthetics of a product?

- The overall aesthetics of a product can be greatly enhanced by steel billets in various ways. Firstly, the appearance of the final product is greatly influenced by the quality and finish of steel billets. Steel billets are commonly used as raw materials in manufacturing processes like forging, rolling, or machining. The sleek and refined look of the end product is achieved by using high-quality steel billets with smooth surfaces and uniform shapes. Furthermore, steel billets offer designers and manufacturers a wide range of possibilities in terms of shape and size. They can be easily customized and transformed into different forms, allowing for intricate and unique designs that enhance the visual appeal of the product. Steel billets can be molded, cut, or manipulated to create complex patterns, textures, or contours, providing endless opportunities for artistic expression. Additionally, the strength and durability of steel billets contribute to the longevity and resilience of the final product. Aesthetics are not solely based on visual appeal but also on the perception of quality. Steel billets, known for their robustness and resistance to corrosion, instill a sense of reliability and sturdiness. This perceived quality enhances the overall attractiveness of the product, making it more appealing to consumers. In conclusion, steel billets play a significant role in enhancing the overall aesthetics of a product by providing a high-quality, customizable, and durable raw material. Their smooth surface, versatility in shaping, and inherent strength enhance the visual appeal, enabling designers to create visually captivating and long-lasting products.

Send your message to us

Converter Continuous Square Steel Billet 3SP 5SP 20MnSi Hot Selling

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords