Hot Rolled Square Steel Billet 3SP 5SP 20MnSi Using Good Quailty Ceramic Fiber Bulk

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Square Steel Billet 3SP 5SP 20MnSi Using Good Quailty Ceramic Fiber Bulk

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

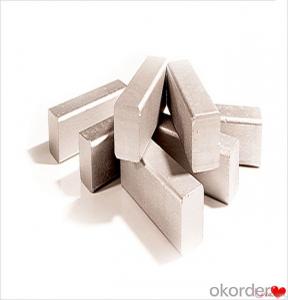

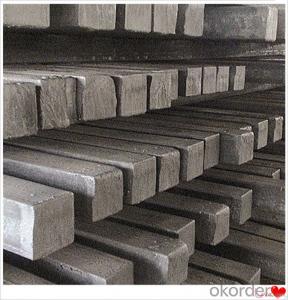

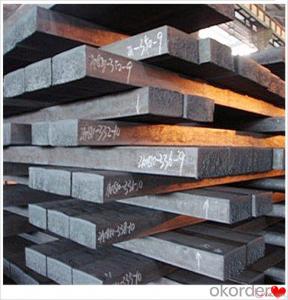

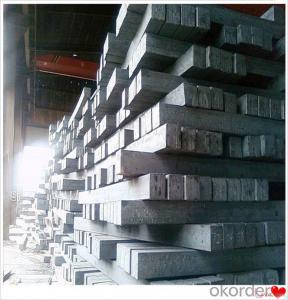

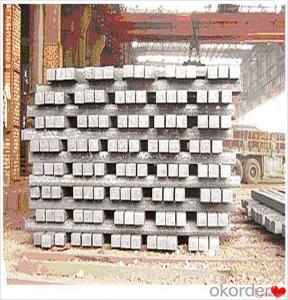

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: How are steel billets used in the manufacturing of automotive engine components?

- Steel billets are used in the manufacturing of automotive engine components as they serve as the raw material from which various engine parts are forged or machined. These billets are heated and shaped into different forms such as crankshafts, connecting rods, camshafts, and valves, which are integral to the functioning of an engine. By using steel billets, manufacturers can ensure the strength, durability, and reliability of these components, resulting in high-performance engines.

- Q: What are the main safety considerations when handling steel billets?

- When handling steel billets, there are several key safety considerations that should be kept in mind to ensure the well-being of workers and prevent accidents. These considerations include: 1. Personal Protective Equipment (PPE): It is crucial for workers to wear appropriate PPE, such as gloves, safety goggles, steel-toed boots, and hard hats. This equipment can provide protection against potential hazards, such as cuts, impact, and flying debris. 2. Proper Lifting Techniques: Steel billets are heavy and can cause strain or injury if lifted incorrectly. Workers should be trained in proper lifting techniques, including bending at the knees, keeping the back straight, and using mechanical aids, such as cranes or forklifts, whenever feasible. 3. Secure Storage and Transportation: Steel billets should be stored and transported in a secure manner to prevent them from falling or shifting, which could lead to crushing or falling hazards. Stacks of billets should be stable and properly secured using appropriate equipment, such as straps or chains. 4. Slip and Fall Prevention: Steel billets, especially when wet or oily, can create slippery surfaces that increase the risk of slips and falls. Proper housekeeping practices, including regular cleaning and the use of anti-slip mats or coatings, can help minimize this risk. 5. Fire and Heat Hazards: Steel billets can reach high temperatures during production or processing. It is important to have adequate fire prevention and firefighting measures in place, such as fire-resistant clothing, fire extinguishers, and proper storage of flammable materials. 6. Hazardous Substances: Some steel billets may be coated with chemicals or have residues that can pose health risks. Workers should be aware of the potential hazards and follow proper handling procedures, including using appropriate ventilation, wearing respiratory protection, and practicing good hygiene. 7. Machine and Equipment Safety: When using machinery or equipment for handling steel billets, it is essential to follow all safety guidelines and precautions, including lockout/tagout procedures, regular maintenance, and proper training on equipment operation. Overall, prioritizing safety when handling steel billets requires a combination of proper training, adherence to safety protocols, and the use of appropriate equipment and protective measures. By following these safety considerations, the risk of accidents and injuries can be significantly reduced.

- Q: What are the dimensions of a typical steel billet?

- The dimensions of a typical steel billet vary depending on its application and the specific requirements of the industry. However, common dimensions for steel billets range from 100mm to 300mm in width and 100mm to 400mm in height, with lengths typically ranging from 3 to 6 meters.

- Q: Can steel billets be used in the production of railway infrastructure?

- Yes, steel billets can be used in the production of railway infrastructure. Steel billets are semi-finished products that are typically used as raw material in the manufacturing of various steel products. In the case of railway infrastructure, steel billets can be further processed and shaped into different components such as rails, sleepers, and fasteners. Rails, the tracks on which trains run, are usually made from steel billets. These billets are heated and passed through a rolling mill to form the desired rail profile. The resulting rail is then further processed to meet specific requirements such as strength, durability, and resistance to wear and fatigue. Similarly, steel billets can also be used in the production of sleepers, which are the supporting structures that hold the rails in place. Sleepers are typically made from prestressed concrete or steel, and steel billets can be used as the raw material for manufacturing steel sleepers. Additionally, steel billets can be used in the production of various fasteners that are essential for railway infrastructure. These include rail clips, bolts, nuts, and washers, which are used to securely fasten rails to sleepers and other components. Overall, steel billets play a crucial role in the production of railway infrastructure. They provide the necessary raw material for manufacturing rails, sleepers, and fasteners, thereby contributing to the construction and maintenance of railway tracks, bridges, and other essential infrastructure elements.

- Q: How are steel billets used in the production of valves and fittings?

- Steel billets are used in the production of valves and fittings as raw material. They are heated, shaped, and machined to form the desired components, ensuring strength, durability, and precision.

- Q: How do steel billets contribute to the overall recyclability of a structure?

- Steel billets play a significant role in enhancing the overall recyclability of a structure. These billets, which are semi-finished steel products, are produced by melting iron ore and other raw materials in a blast furnace. Due to their composition and manufacturing process, steel billets possess several characteristics that contribute to the recyclability of a structure. First and foremost, steel is one of the most recycled materials on the planet. Steel billets can be recycled indefinitely without losing their quality or integrity. This means that at the end of a structure's lifespan, the steel components can be easily dismantled and the steel billets can be melted down to produce new steel products. The ability to recycle steel billets reduces the need for extracting and refining new iron ore, which in turn conserves natural resources and minimizes the environmental impact associated with mining activities. Furthermore, the recycling process of steel billets requires significantly less energy compared to the production of steel from raw materials. Recycling steel billets consumes around 75% less energy compared to producing steel from scratch. This energy efficiency not only reduces greenhouse gas emissions but also contributes to cost savings during the manufacturing process. By using recycled steel billets in the construction of structures, we can reduce the carbon footprint and promote sustainable practices in the construction industry. In addition to the environmental benefits, the use of steel billets in structures also offers practical advantages. Steel is known for its strength, durability, and resilience, making it an ideal material for constructing robust and long-lasting structures. By incorporating steel billets, structures can be designed to withstand various environmental conditions, such as earthquakes and hurricanes, ensuring the safety and longevity of the building. This longevity aspect is crucial in terms of recyclability, as it allows the structure to serve its purpose for an extended period before being recycled. In conclusion, steel billets contribute significantly to the overall recyclability of a structure. Their ability to be recycled indefinitely, reduced energy consumption during the recycling process, and practical advantages such as strength and durability make steel billets an excellent choice for constructing sustainable and recyclable structures. By incorporating steel billets, we can promote a circular economy, conserve natural resources, reduce emissions, and create a more sustainable future for construction.

- Q: What are the potential applications of steel billets in the mining aftermarket?

- Steel billets have a wide range of potential applications in the mining aftermarket. One of the key uses of steel billets is in the manufacturing of heavy machinery and equipment used in mining operations. These include components like gears, shafts, and cylinders, which require high strength and durability to withstand the harsh conditions of mining activities. Steel billets can also be used in the production of wear-resistant parts, such as cutting edges, buckets, and liners for mining equipment. These parts are subject to intense wear and tear, and the use of steel billets ensures their longevity and reliability. Furthermore, steel billets can be utilized in the construction of mine support structures, such as beams, columns, and frames. These structures provide stability and safety to mining operations, and steel billets offer the necessary strength and load-bearing capacity for their construction. In addition to equipment and structures, steel billets can be employed in the production of tools and accessories used in mining activities. For example, drill bits, hammers, and chisels require high strength and toughness to effectively break through hard rock formations, and steel billets provide the ideal material for their fabrication. Overall, the potential applications of steel billets in the mining aftermarket are vast and encompass various aspects of mining operations. From heavy machinery and equipment manufacturing to wear-resistant parts production and mine support structures, steel billets offer the necessary strength, durability, and reliability required to optimize mining processes.

- Q: How are steel billets used in the production of sheet metal?

- Steel billets are heated and then rolled into thin sheets to create sheet metal. This process involves passing the billets through a series of rollers, which gradually reduce their thickness. These sheets can then be further processed and shaped to create various products, such as car bodies, appliances, and construction materials.

- Q: Fish pole carbon cloth tcf. Vcf. Svf. Hcf. On behalf of what?

- Carbon cloth classification, a semicolon after the term, usually called HVF and SVF, where SVF is divided into VCF and so on! The index of carbon fiber is T (ton), common carbon part is 20T-30T commonly. HVF is 30T-40T, SVF is 40T-60T. SVF lighter than HVF, higher strength, better elasticity of the material of products: Di 46T SVF meaning 60T ultra high strength and high modulus carbon fiber cloth, HVF carbon fiber reinforced 30T 40T strength and high modulus. But the domestic ordinary carbon fishing rod material is generally 24T carbon fiber cloth. The higher the T value, the higher the strength and elasticity of the material.

- Q: What does "billet" mean?

- Steelmaking and continuous casting of steel products are mainly used for steel rolling, such as round bar, wire rod, sheet metal and so on

Send your message to us

Hot Rolled Square Steel Billet 3SP 5SP 20MnSi Using Good Quailty Ceramic Fiber Bulk

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords