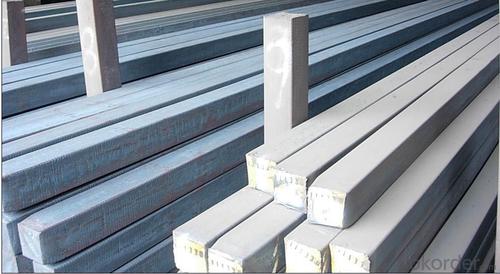

Hot Rolled Square Steel Billet 3SP Standard 120mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Hot Rolled Square Steel Billet 3SP Standard 120mm

Description of Hot Rolled Square Steel Billet 3SP Standard 120mm

PPGI is made by cold rolled steel sheet and galvanized steel sheets as baseplate, through the surface pretreatment (degreasing, cleaning, chemical conversion processing), coated by the method of continuous coatings (roller coating method),

and after roasting and cooling. Zinc coating: Z60, Z80, Z100, Z120, Z180, Z275, G30, G60, G90

Alu-zinc coating: AZ60, AZ80, AZ100, AZ120, AZ180, G30, G60, G90

Main Feature of Hot Rolled Square Steel Billet 3SP Standard 120mm

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve.

Applications of Hot Rolled Square Steel Billet 3SP Standard 120mm

1) Automotive bodies: filters, fuel tanks, etc.

2) Construction materials: roofings, welding pipes,

3) Electric and electronic appliances: computer cans, etc.

4) Steel cans: containers, etc.

5) Steel furniture: washing machines, refrigerators, microwaves, etc.

6) Drums

7) Office equipment: printer, recorders, etc.

8) Motors and transformers

Specifications of Hot Rolled Square Steel Billet 3SP Standard 120mm

| Classified symbol | Yield Point Minimum N/mm2 | Tensile Strength Minimum | Elongation Minimum % | Application | ||||

| N/mm2 | Nominal Thickness mm (t) | |||||||

| JIS | Yogic | 0.25-0.4 | 0.4-0.6 | 0.6-1.0 | 1.0-1.6 | |||

| G3312 | specification | |||||||

| CGCC | CGCC | -205 | -270 | -20 | -21 | -24 | -24 | Commercial |

| CGCD | CGCD | --- | 270 | --- | 27 | 31 | 32 | Drawing |

| --- | CG340 | 245 | 340 | 20 | 20 | 20 | 20 | Structural |

| CGC400 | CG400 | 295 | 400 | 16 | 17 | 18 | 18 | Structural |

| CGC440 | CG440 | 335 | 440 | 14 | 15 | 16 | 18 | Structural |

| CGC490 | CG490 | 365 | 490 | 12 | 13 | 14 | 16 | Structural |

| CGC570 | CG570 | 560 | 570 | --- | --- | --- | --- | Structural |

| ASTM Designation | Yield Point Minimum | Tensile Strength Minimum | Elongation Minimum % | Application | Q/BQB 445-2004(China standard) | ASM A653/A653M | JISG 3312 | |

| ksi(MPa) | ksi(MPa) | TDC51D+Z | (CS TYPE A+Z) | CGCC | ||||

| A653(M)-99 CS TYPE A,B,C | --- | --- | --- | Commercial | TDC52D+Z | CGCD | ||

| A653(M)-99 FS | --- | --- | --- | Lock Forming | TS250GD+Z | (G250+Z) | - | |

| A653(M)-99 DS | --- | --- | --- | Drawing | TS300GS+Z | (G300+Z) | CGC 400 | |

| A653(M)-99 SS Grade33(230) | 33(230) | 45(310) | 20 | Structural | TS350GD+Z | (G350+Z) | CGC490 | |

| A653(M)-99 SS Grade37(255) | 37(255) | 52(360) | 18 | Structural | TS550GD+Z | (G550+Z) | CGC570 | |

| A653(M)-99 SS Grade40(275) | 40(275) | 55(380) | 16 | Structural | ||||

| A653(M)-99 SS Grade50(345) | 50(345) | 65(450) | 12 | Structural | ||||

| A653(M)-99 SS Grade80(550) | 80(550) | 82(570) | --- | Structural | ||||

FAQ of Hot Rolled Square Steel Billet 3SP Standard 120mm

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

1, ISO, BV, CE, SGS approved.

2, Competitive price and quality.

3, Efficient service team online for 24 hours.

4, Smooth production ability(50000tons/month) .

5, quick delivery and standard exporting package.

6, Flexible payment with T/T, L/C, Paypal, Kunlun bank, etc

- Q: What are the main factors affecting the machined surface quality of steel billets?

- The machined surface quality of steel billets is significantly influenced by various main factors. These factors encompass the following: 1. Cutting Speed: The speed at which the tool traverses the billet's surface plays a vital role in determining the surface quality. Higher cutting speeds can generate excessive heat, resulting in thermal damage and subpar quality. Hence, it is crucial to identify the optimal cutting speed to attain a high-quality machined surface. 2. Feed Rate: The rate at which the tool advances into the material during machining is referred to as the feed rate. A high feed rate can cause excessive tool wear, leading to poor surface quality. Conversely, a low feed rate may induce chatter or vibration, causing surface irregularities. Striking the right balance is essential to achieve a smooth and high-quality machined surface. 3. Tool Geometry: The shape, angle, and edge sharpness of the cutting tool significantly impact the surface quality. Tool geometry affects chip formation and the interaction between the tool and the billet. Proper tool geometry can minimize cutting forces, vibration, and improve chip evacuation, resulting in an enhanced surface finish. 4. Cutting Fluid: The choice and application of cutting fluids exert a substantial influence on the surface quality of machined steel billets. Cutting fluids serve multiple purposes, such as cooling the tool and workpiece, lubricating the cutting process, and removing chips. Appropriate selection and application of cutting fluids can reduce friction, heat generation, and tool wear, thereby enhancing surface quality. 5. Billet Material and Hardness: The material composition and hardness of the steel billet also affect the machined surface quality. Different steels exhibit varying levels of machinability, with some being more susceptible to issues like work hardening or built-up edge formation. Harder materials generally necessitate robust cutting tools and specific machining techniques to achieve the desired surface quality. 6. Machine Rigidity and Stability: The rigidity and stability of the machine employed for machining steel billets are crucial factors influencing surface quality. Any deflection or vibration in the machine tool can result in subpar surface finish and dimensional accuracy. Therefore, ensuring proper machine setup, alignment, and maintenance is essential to minimize unwanted vibrations and maximize surface quality. In summary, a combination of the aforementioned factors, along with appropriate cutting parameters and machining techniques, is indispensable for achieving a high-quality machined surface on steel billets. Adjusting these factors based on the billet's specific characteristics and desired surface finish can optimize the machining process and enhance the overall quality of the final product.

- Q: What are the main steel billet producing countries?

- The main steel billet producing countries are China, India, Russia, Japan, and the United States. China is the largest producer of steel billets, accounting for approximately half of the global production. This is followed by India, which has also emerged as a major player in the steel industry. Russia, known for its vast reserves of iron ore and coal, is another significant producer of steel billets. Japan, a highly industrialized nation, has a well-established steel industry and contributes significantly to the global production. Lastly, the United States, with its advanced technology and large steel mills, also plays a significant role in steel billet production. These countries not only produce steel billets for domestic consumption but also export to meet the global demand for steel products.

- Q: How are steel billets used in the manufacturing of kitchen appliances?

- Steel billets are used in the manufacturing of kitchen appliances as the primary raw material. These billets are heated and then shaped or molded into various components such as bodies, frames, handles, or cooktops, which form the structural foundation of kitchen appliances. The high strength and durability of steel make it an ideal choice for withstanding the rigors of everyday use in kitchen appliances, ensuring their longevity and quality.

- Q: How do steel billets contribute to the manufacturing of construction equipment?

- Steel billets play a crucial role in the manufacturing of construction equipment. These billets are essentially semi-finished steel products that have been cast into a specific shape and size. They are typically rectangular or square in shape and serve as the starting point for further processing. One of the main ways in which steel billets contribute to the manufacturing of construction equipment is by providing a high-quality raw material. Steel is known for its exceptional strength, durability, and resistance to various environmental factors. By using steel billets, manufacturers can ensure that the construction equipment they produce will be able to withstand the harsh conditions and heavy loads that are often encountered in the construction industry. Steel billets are also used to produce various components of construction equipment. These components can include frames, beams, brackets, and other structural elements. By using steel billets, manufacturers can easily shape and form these components to meet the specific design requirements of the equipment. This flexibility allows for the creation of equipment that is not only strong and durable but also lightweight and efficient. Furthermore, steel billets are often used in the manufacturing of construction equipment due to their cost-effectiveness. Steel is a highly recyclable material, which means that it can be reused and repurposed multiple times without losing its properties. This makes steel billets a sustainable and environmentally friendly choice for manufacturers. In summary, steel billets are an essential component in the manufacturing of construction equipment. They provide a high-quality raw material that is strong, durable, and resistant to various environmental factors. Steel billets also allow for the production of customized components that meet specific design requirements. Additionally, their cost-effectiveness and recyclability make them a sustainable choice for manufacturers. Overall, steel billets contribute significantly to the production of construction equipment, ensuring that it meets the highest standards of quality and performance.

- Q: Can steel billets be used in the production of kitchenware?

- Yes, steel billets can be used in the production of kitchenware. Steel billets can be further processed and shaped into various kitchenware items such as pots, pans, knives, utensils, and cookware. The malleability and durability of steel make it a suitable material for kitchenware production, providing strength, heat resistance, and longevity to the finished products.

- Q: What are the different types of steel billet rolling processes?

- There are several types of steel billet rolling processes, including hot rolling, cold rolling, and warm rolling. Hot rolling involves heating the billet to a high temperature and then passing it through a series of rollers to shape it into the desired form. Cold rolling, on the other hand, is performed at room temperature and involves passing the billet through rollers to achieve a desired thickness or shape. Warm rolling is a combination of hot and cold rolling, where the billet is heated to a lower temperature compared to hot rolling but higher than room temperature. Each of these processes has its own advantages and is used for different applications in the steel industry.

- Q: How do steel billets contribute to the overall cost-effectiveness of a project?

- There are several ways in which steel billets contribute to the cost-effectiveness of a project. To begin with, steel billets serve as the initial material for various steel products, such as beams, bars, and sheets. Manufacturers can produce these products in a cost-effective manner by utilizing steel billets, which are usually less expensive than finished steel products. Furthermore, the use of steel billets allows for the efficient utilization of resources. They can be easily melted down and shaped into different forms and sizes, thereby reducing waste during the production process. This adaptability diminishes the amount of raw material required, resulting in cost savings. In addition, steel billets possess exceptional strength and durability characteristics. By incorporating steel billets into construction projects, engineers can ensure the solidity and longevity of the structures. This helps to decrease maintenance and repair expenses over time, ultimately enhancing the project's cost-effectiveness. Moreover, steel billets are readily available in the market, making them a cost-effective option for projects with tight schedules. Manufacturers can easily procure steel billets from various suppliers, ensuring a consistent supply of material for the project. Lastly, steel billets contribute to cost-effectiveness through their recyclability. Steel is one of the most widely recycled materials globally, and the use of recycled steel billets can significantly reduce production costs. The recycling of steel billets also aids in minimizing the environmental impact of a project, making it a more sustainable and cost-effective choice. All in all, steel billets play a crucial role in enhancing the cost-effectiveness of a project by providing an economical starting material, reducing waste, ensuring durability, facilitating availability, and promoting recycling.

- Q: What is the chemical composition of steel billets?

- The chemical composition of steel billets typically consists of iron as the primary element, along with varying amounts of carbon, manganese, silicon, sulfur, and phosphorus. The exact composition may vary depending on the specific grade and intended use of the steel billets. Carbon is usually present in small amounts, typically ranging from 0.02% to 0.5%, as it helps to increase the strength and hardness of the steel. Manganese is often added to improve the toughness and hardenability of the steel, while silicon helps in deoxidizing the metal and enhancing its strength. Sulfur and phosphorus are impurities that are typically kept at low levels, as they can negatively affect the mechanical properties of the steel. Additionally, small amounts of other elements such as chromium, nickel, and molybdenum may be added to enhance specific properties of the steel, such as corrosion resistance or high-temperature strength.

- Q: How are steel billets used in the production of industrial valves?

- Steel billets are used in the production of industrial valves as they serve as the raw material for shaping and forming various valve components, such as bodies, bonnets, stems, and discs. Through machining, forging, and welding processes, the steel billets are transformed into the required shapes and sizes, ensuring the strength and durability of the valves.

- Q: What industries rely heavily on steel billets?

- Several industries heavily rely on steel billets as a crucial raw material for their manufacturing processes. One such industry is the construction industry, which uses steel billets to fabricate structural components such as beams, columns, and reinforcement bars. Steel billets provide the required strength and durability necessary for constructing buildings, bridges, and other infrastructure projects. The automotive industry also heavily relies on steel billets. Steel billets are used to manufacture various automotive parts, including engine components, chassis, and suspension systems. The high strength and versatility of steel billets make them ideal for producing parts that can withstand rigorous conditions and ensure vehicle safety. In addition, the oil and gas industry heavily depends on steel billets for the production of pipelines, drill pipes, and other equipment used in exploration, extraction, and transportation processes. Steel billets are preferred due to their corrosion resistance, high pressure resistance, and ability to withstand extreme temperatures. Moreover, the machinery and equipment manufacturing industry extensively uses steel billets as a primary material for producing a wide range of machinery, including industrial machinery, agricultural equipment, and heavy-duty machinery. Steel billets provide the necessary strength, toughness, and machinability required for these applications. Furthermore, the aerospace industry relies on steel billets for manufacturing various aircraft components, such as landing gear, structural frames, and engine parts. Steel billets are chosen for their high strength-to-weight ratio, heat resistance, and ability to withstand the demanding conditions of aerospace applications. Overall, steel billets play a vital role in several industries, including construction, automotive, oil and gas, machinery and equipment manufacturing, and aerospace. The unique properties of steel billets make them indispensable in these industries, ensuring the production of strong, durable, and reliable products.

Send your message to us

Hot Rolled Square Steel Billet 3SP Standard 120mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords