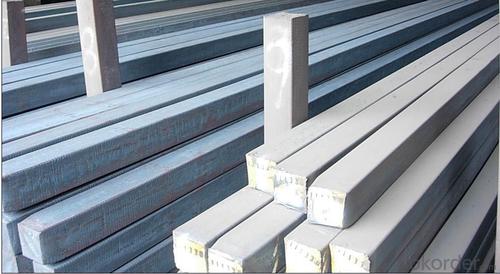

Hot Rolled Square Steel Billet 3SP Standard 125mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Hot Rolled Square Steel Billet 3SP Standard 125mm

Description of Hot Rolled Square Steel Billet 3SP Standard 125mm

PPGI is made by cold rolled steel sheet and galvanized steel sheets as baseplate, through the surface pretreatment (degreasing, cleaning, chemical conversion processing), coated by the method of continuous coatings (roller coating method),

and after roasting and cooling. Zinc coating: Z60, Z80, Z100, Z120, Z180, Z275, G30, G60, G90

Alu-zinc coating: AZ60, AZ80, AZ100, AZ120, AZ180, G30, G60, G90

Main Feature of Hot Rolled Square Steel Billet 3SP Standard 125mm

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve.

Applications of Hot Rolled Square Steel Billet 3SP Standard 125mm

1) Automotive bodies: filters, fuel tanks, etc.

2) Construction materials: roofings, welding pipes,

3) Electric and electronic appliances: computer cans, etc.

4) Steel cans: containers, etc.

5) Steel furniture: washing machines, refrigerators, microwaves, etc.

6) Drums

7) Office equipment: printer, recorders, etc.

8) Motors and transformers

Specifications of Hot Rolled Square Steel Billet 3SP Standard 125mm

| Classified symbol | Yield Point Minimum N/mm2 | Tensile Strength Minimum | Elongation Minimum % | Application | ||||

| N/mm2 | Nominal Thickness mm (t) | |||||||

| JIS | Yogic | 0.25-0.4 | 0.4-0.6 | 0.6-1.0 | 1.0-1.6 | |||

| G3312 | specification | |||||||

| CGCC | CGCC | -205 | -270 | -20 | -21 | -24 | -24 | Commercial |

| CGCD | CGCD | --- | 270 | --- | 27 | 31 | 32 | Drawing |

| --- | CG340 | 245 | 340 | 20 | 20 | 20 | 20 | Structural |

| CGC400 | CG400 | 295 | 400 | 16 | 17 | 18 | 18 | Structural |

| CGC440 | CG440 | 335 | 440 | 14 | 15 | 16 | 18 | Structural |

| CGC490 | CG490 | 365 | 490 | 12 | 13 | 14 | 16 | Structural |

| CGC570 | CG570 | 560 | 570 | --- | --- | --- | --- | Structural |

| ASTM Designation | Yield Point Minimum | Tensile Strength Minimum | Elongation Minimum % | Application | Q/BQB 445-2004(China standard) | ASM A653/A653M | JISG 3312 | |

| ksi(MPa) | ksi(MPa) | TDC51D+Z | (CS TYPE A+Z) | CGCC | ||||

| A653(M)-99 CS TYPE A,B,C | --- | --- | --- | Commercial | TDC52D+Z | CGCD | ||

| A653(M)-99 FS | --- | --- | --- | Lock Forming | TS250GD+Z | (G250+Z) | - | |

| A653(M)-99 DS | --- | --- | --- | Drawing | TS300GS+Z | (G300+Z) | CGC 400 | |

| A653(M)-99 SS Grade33(230) | 33(230) | 45(310) | 20 | Structural | TS350GD+Z | (G350+Z) | CGC490 | |

| A653(M)-99 SS Grade37(255) | 37(255) | 52(360) | 18 | Structural | TS550GD+Z | (G550+Z) | CGC570 | |

| A653(M)-99 SS Grade40(275) | 40(275) | 55(380) | 16 | Structural | ||||

| A653(M)-99 SS Grade50(345) | 50(345) | 65(450) | 12 | Structural | ||||

| A653(M)-99 SS Grade80(550) | 80(550) | 82(570) | --- | Structural | ||||

FAQ of Hot Rolled Square Steel Billet 3SP Standard 125mm

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

1, ISO, BV, CE, SGS approved.

2, Competitive price and quality.

3, Efficient service team online for 24 hours.

4, Smooth production ability(50000tons/month) .

5, quick delivery and standard exporting package.

6, Flexible payment with T/T, L/C, Paypal, Kunlun bank, etc.

- Q: What are the different types of surface treatment methods used for steel billets?

- Some of the different types of surface treatment methods used for steel billets include pickling, shot blasting, and galvanizing. Pickling involves immersing the billets in an acid solution to remove scale and impurities. Shot blasting uses high-speed particles to clean and roughen the surface of the billets. Galvanizing involves coating the billets with a layer of zinc to protect against corrosion. Other methods, such as painting or powder coating, may also be used for specific applications.

- Q: How are steel billets used in the manufacturing of food processing machinery?

- Food processing machinery relies on steel billets for the production of various components and structures. These billets undergo heating and rolling processes to form steel bars, rods, or sheets of different shapes and sizes. These steel products are then utilized in the construction of the framework, body, and other parts of the machinery. Steel's high strength and durability make it an ideal choice for food processing machinery, which often operates in harsh conditions and requires resistance to corrosion, wear, and high temperatures. Steel billets are carefully selected for their quality and suitability for the intended application. When constructing food processing machinery, steel billets are employed in fabricating crucial components like cutting blades, mixing paddles, conveyor belts, and grinding plates. These components are vital for the efficient processing and handling of food products, ensuring consistent quality and safety. Furthermore, steel billets are also used in manufacturing structural supports, frames, and housing for machinery. These structures provide the necessary stability, rigidity, and support to ensure the proper functioning and longevity of the food processing equipment. In conclusion, steel billets play a vital role in the manufacturing of food processing machinery as they provide the essential raw material required to create durable, reliable, and efficient equipment. The quality and characteristics of steel contribute to the performance, safety, and hygiene standards demanded in the food processing industry.

- Q: What are the main factors affecting the fatigue strength of stainless steel billets?

- The main factors affecting the fatigue strength of stainless steel billets include the composition and microstructure of the steel, the presence of surface defects or imperfections, the level of applied stress or load, the presence of corrosive environments, and the temperature at which the billets are operating.

- Q: What is the role of steel billets in the manufacturing of cutting tools?

- The manufacturing of cutting tools heavily relies on steel billets. These billets act as the primary material from which the cutting tool is forged or machined. Typically, steel billets are composed of high-quality steel alloys, which possess vital properties like hardness, toughness, and wear resistance that are necessary for cutting tools. To initiate the manufacturing process, the steel billets are heated to a specific temperature called the forging temperature. This temperature allows the steel to become malleable, making it easier to shape and mold into the desired cutting tool. The heated billets are then subjected to a forging process using specialized equipment, where they are struck or pressed to shape them into the desired form, such as drills, saws, or blades. Following the initial forging, the billets undergo further machining to refine their shape and dimensions. Machining processes like milling, turning, and grinding are employed to eliminate excess material, achieve precise dimensions required for the cutting tool, and create the desired cutting edge geometry. The quality of the steel billets used in the manufacturing process significantly impacts the performance and durability of the cutting tool. Steel billets with high carbon content and alloying elements like chromium, vanadium, or tungsten are often preferred as they enhance the hardness, strength, and wear resistance of the cutting tool. These properties are essential to ensure that the cutting tool can withstand the high forces, temperatures, and abrasive conditions it will encounter during use. In conclusion, steel billets serve as the foundation for manufacturing cutting tools. They provide the necessary raw material and properties required to create high-quality cutting tools that demonstrate exceptional performance, durability, and precision.

- Q: How do steel billets contribute to the energy industry?

- The energy industry heavily relies on steel billets, as they serve as the primary raw material for manufacturing various energy-related equipment and infrastructure. Steel billets, which are semi-finished steel products, find extensive use in the construction of power plants, oil and gas pipelines, wind turbines, and other energy infrastructure projects. A crucial application of steel billets in the energy industry lies in the production of power plant components. Boilers, turbines, and generators, which require high levels of strength, durability, and resistance to high temperatures and pressure, are manufactured using steel billets. By incorporating steel billets, power plant manufacturers ensure the reliability and longevity of their equipment, thereby contributing to the overall efficiency and stability of the energy generation process. Steel billets also play a vital role in the construction of oil and gas pipelines. These pipelines are essential for transporting oil, natural gas, and other energy resources from production sites to refineries and end-users. Steel billets are used to manufacture the large-diameter pipes that form the foundation of these pipelines. The strength, toughness, and corrosion resistance of steel billets guarantee the integrity and safety of the pipeline infrastructure, minimizing the risk of leaks or failures that could result in energy supply disruptions or environmental damage. Moreover, steel billets are indispensable in the production of wind turbines, which are rapidly emerging as a renewable energy source. The towers and foundations of wind turbines are primarily made of steel, and steel billets are employed in their manufacturing due to their exceptional strength and load-bearing capabilities. By utilizing steel billets, wind turbine manufacturers can construct tall and sturdy towers capable of supporting the rotor and ensuring the efficient conversion of wind energy into electricity. In conclusion, steel billets significantly contribute to the energy industry by enabling the construction of robust and reliable infrastructure. The strength, durability, and versatility of steel billets make them an ideal material for energy-related projects, promoting the efficient and sustainable generation, transportation, and utilization of energy resources.

- Q: How do steel billets contribute to the overall aesthetics of a structure?

- Steel billets, which are semi-finished steel products, do not directly contribute to the overall aesthetics of a structure. However, they play a crucial role in the manufacturing process of various steel components such as beams, columns, and decorative elements. These components, when properly designed and incorporated into a structure, can enhance its aesthetic appeal by providing strength, durability, and architectural uniqueness.

- Q: What are the different types of straightening methods used for steel billets?

- Steel billets can be straightened using various methods, depending on specific requirements and desired outcomes. These methods encompass: 1. Roller Straightening: By passing the steel billets through a series of rollers, pressure is applied in different directions to achieve straightness. Rollers can be adjusted to target specific areas that may be bent or twisted. 2. Hydraulic Straightening: Employing hydraulic presses, pressure is exerted on the billets either in a single or multiple directions. Adjustments can be made to attain the desired level of straightness. 3. Heat Straightening: This method involves heating the bent or twisted sections of the steel billets and using hydraulic or mechanical tools to straighten them. The heat softens the steel, simplifying the reshaping process. 4. Hammering: A conventional technique where skilled workers manually reshape the billets using hammers and anvils. This method necessitates a high level of skill and precision to achieve the desired straightness. 5. Magnetic Straightening: Employing magnetic fields, this non-contact method applies forces to the steel billets and straightens them. It is often implemented for smaller and thinner billets to avoid damage or distortion caused by other methods. Each straightening method has its own advantages and limitations. The choice of method depends on various factors, such as billet size and thickness, required level of straightness, and available equipment and resources.

- Q: Are steel billets used in the production of electrical transmission towers?

- The utilization of steel billets is widespread in the manufacturing of electrical transmission towers. At the onset of the production process, steel billets serve as the primary form of steel. They are typically shaped and sized through hot rolling, resulting in various sections and components required for constructing transmission towers. Due to its remarkable strength and durability, steel emerges as the perfect material for such structures, which must endure harsh environmental conditions and uphold heavy electrical conductors. Additionally, steel possesses exceptional electrical conductivity properties, a vital characteristic for ensuring the efficient transmission of electricity through the towers. In summary, steel billets assume a pivotal role in the creation of electrical transmission towers, guaranteeing their strength, durability, and efficiency.

- Q: How are steel billets used in the production of agricultural machinery?

- Steel billets are an essential component in the production of agricultural machinery. These billets, which are semi-finished metal products, are used as raw material for manufacturing various parts and components of agricultural machinery. Agricultural machinery, such as tractors, harvesters, and plows, require strong and durable structures to withstand the demanding conditions of agricultural operations. Steel billets provide the ideal material for constructing these robust structures due to their high strength, excellent mechanical properties, and resistance to corrosion. Steel billets are first melted and cast into their basic shape, which is typically a rectangular or square cross-section. They are then further processed through various techniques like forging, rolling, or extrusion to shape them into specific parts required for agricultural machinery. These parts may include axles, gears, shafts, blades, and brackets, among others. The use of steel billets in agricultural machinery production ensures the final products have the necessary strength, durability, and reliability to perform efficiently in farm operations. These machines often operate in harsh environments, such as uneven terrains, heavy loads, and exposure to moisture and chemicals. Steel's inherent properties make it the ideal choice for ensuring the longevity and performance of agricultural machinery. Moreover, steel billets offer versatility in design and customization. Agricultural machinery manufacturers can easily modify the shape, size, and dimensions of steel billets during the production process to meet the specific requirements of each machine. This flexibility allows for the creation of more efficient and specialized equipment to cater to various agricultural tasks. In conclusion, steel billets play a crucial role in the production of agricultural machinery, providing the necessary strength and durability required for farm operations. Their versatility, strength, and resistance to corrosion make them an ideal choice for manufacturing various components of agricultural machinery, ensuring the reliability and longevity of these machines in demanding agricultural environments.

- Q: What does the billet of the steel plant refer to?And steel what is the difference?

- Many species, usually by chemical composition, production process, rolling shape, supply form, diameter, and use in the structure the classification of steel bars for concrete reinforcement refers to straight or strip steel plate reinforced concrete reinforcement steel, its shape is divided into round steel bar and deformed steel two. Steel bars in concrete under tensile stress.

Send your message to us

Hot Rolled Square Steel Billet 3SP Standard 125mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords