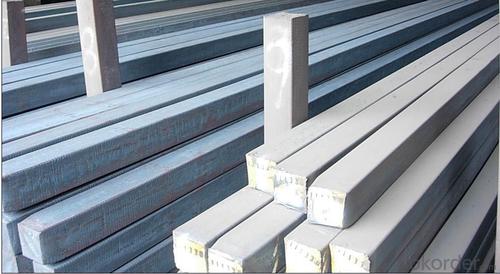

Hot Rolled Square Steel Billet 3SP Standard 115mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Hot Rolled Square Steel Billet 3SP Standard 115mm

Description of Hot Rolled Square Steel Billet 3SP Standard 115mm

PPGI is made by cold rolled steel sheet and galvanized steel sheets as baseplate, through the surface pretreatment (degreasing, cleaning, chemical conversion processing), coated by the method of continuous coatings (roller coating method),

and after roasting and cooling. Zinc coating: Z60, Z80, Z100, Z120, Z180, Z275, G30, G60, G90

Alu-zinc coating: AZ60, AZ80, AZ100, AZ120, AZ180, G30, G60, G90

Main Feature of Hot Rolled Square Steel Billet 3SP Standard 115mm

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve.

Applications of Hot Rolled Square Steel Billet 3SP Standard 115mm

1) Automotive bodies: filters, fuel tanks, etc.

2) Construction materials: roofings, welding pipes,

3) Electric and electronic appliances: computer cans, etc.

4) Steel cans: containers, etc.

5) Steel furniture: washing machines, refrigerators, microwaves, etc.

6) Drums

7) Office equipment: printer, recorders, etc.

8) Motors and transformers

Specifications of Hot Rolled Square Steel Billet 3SP Standard 115mm

| Classified symbol | Yield Point Minimum N/mm2 | Tensile Strength Minimum | Elongation Minimum % | Application | ||||

| N/mm2 | Nominal Thickness mm (t) | |||||||

| JIS | Yogic | 0.25-0.4 | 0.4-0.6 | 0.6-1.0 | 1.0-1.6 | |||

| G3312 | specification | |||||||

| CGCC | CGCC | -205 | -270 | -20 | -21 | -24 | -24 | Commercial |

| CGCD | CGCD | --- | 270 | --- | 27 | 31 | 32 | Drawing |

| --- | CG340 | 245 | 340 | 20 | 20 | 20 | 20 | Structural |

| CGC400 | CG400 | 295 | 400 | 16 | 17 | 18 | 18 | Structural |

| CGC440 | CG440 | 335 | 440 | 14 | 15 | 16 | 18 | Structural |

| CGC490 | CG490 | 365 | 490 | 12 | 13 | 14 | 16 | Structural |

| CGC570 | CG570 | 560 | 570 | --- | --- | --- | --- | Structural |

| ASTM Designation | Yield Point Minimum | Tensile Strength Minimum | Elongation Minimum % | Application | Q/BQB 445-2004(China standard) | ASM A653/A653M | JISG 3312 | |

| ksi(MPa) | ksi(MPa) | TDC51D+Z | (CS TYPE A+Z) | CGCC | ||||

| A653(M)-99 CS TYPE A,B,C | --- | --- | --- | Commercial | TDC52D+Z | CGCD | ||

| A653(M)-99 FS | --- | --- | --- | Lock Forming | TS250GD+Z | (G250+Z) | - | |

| A653(M)-99 DS | --- | --- | --- | Drawing | TS300GS+Z | (G300+Z) | CGC 400 | |

| A653(M)-99 SS Grade33(230) | 33(230) | 45(310) | 20 | Structural | TS350GD+Z | (G350+Z) | CGC490 | |

| A653(M)-99 SS Grade37(255) | 37(255) | 52(360) | 18 | Structural | TS550GD+Z | (G550+Z) | CGC570 | |

| A653(M)-99 SS Grade40(275) | 40(275) | 55(380) | 16 | Structural | ||||

| A653(M)-99 SS Grade50(345) | 50(345) | 65(450) | 12 | Structural | ||||

| A653(M)-99 SS Grade80(550) | 80(550) | 82(570) | --- | Structural | ||||

FAQ of Hot Rolled Square Steel Billet 3SP Standard 115mm

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

1, ISO, BV, CE, SGS approved.

2, Competitive price and quality.

3, Efficient service team online for 24 hours.

4, Smooth production ability(50000tons/month) .

5, quick delivery and standard exporting package.

6, Flexible payment with T/T, L/C, Paypal, Kunlun bank, etc .

- Q: How are steel billets different from steel ingots?

- Steel billets and steel ingots are both intermediate products in the steel manufacturing process, but they differ in terms of their shape and size. Steel billets are smaller and have a square or rectangular cross-section, typically measuring less than 36 square inches. In contrast, steel ingots are larger and have a more irregular shape, often weighing several tons. Additionally, steel billets are typically produced using continuous casting methods, while steel ingots are typically made through traditional ingot casting processes.

- Q: How are steel billets used in the manufacturing of construction equipment?

- The production of construction equipment heavily relies on steel billets, which are indispensable. These semi-finished steel products serve as the primary material for manufacturing different components and structures used in construction machinery. One of the key applications of steel billets in construction equipment manufacturing is in the forging and casting processes. These billets are subjected to high temperatures and then shaped and sized according to the specific requirements of the machinery being produced. Commonly manufactured components using this method include gears, connecting rods, axle shafts, and hydraulic cylinders. Additionally, steel billets find use in creating structural components for construction equipment. Through hot rolling or cold drawing processes, these billets are transformed into beams, columns, and plates. These structural components provide the necessary strength and stability to ensure durability and long-lasting performance. Moreover, steel billets are crucial in fabricating frames and chassis for construction machinery. By cutting, shaping, and welding the billets together, a sturdy and robust framework is formed, serving as the backbone of the equipment. This framework provides structural integrity, support, and rigidity to withstand heavy loads, vibrations, and harsh working conditions. Furthermore, steel billets are employed in the creation of other essential parts of construction equipment, including buckets, blades, cutting edges, and tracks. These parts are vital for the efficient operation of machinery such as excavators, bulldozers, cranes, and loaders. In summary, the significance of steel billets in the manufacturing of construction equipment cannot be overstated. They provide the necessary raw material for forging, casting, and fabricating various components and structures. The use of high-quality steel billets ensures that construction equipment possesses the required strength, durability, and resilience to perform optimally in demanding construction environments.

- Q: How are steel billets used in the manufacturing of storage tanks?

- Steel billets serve as the primary raw material in the manufacturing of storage tanks. These semi-finished metal forms act as the starting point for producing steel plates or sheets, which are later used to construct the tank walls and base. Once obtained, the steel billets undergo heating and are then passed through a series of rollers to gradually shape them into the desired form. This process, known as hot rolling, is essential for creating the necessary thickness and dimensions required for the storage tank. Following the hot rolling process, the steel billets undergo further processing to eliminate any surface impurities or imperfections using a technique called descaling. This step guarantees the quality and durability of the final tank structure. Next, the steel billets are cut into smaller pieces, referred to as plates or sheets, which are then shaped and welded together to form the tank shell. These plates are meticulously cut and shaped according to specific engineering drawings and designs, ensuring that the tank meets the required specifications for strength, capacity, and structural integrity. Apart from the tank shell, steel billets are also used in manufacturing the tank's base or floor. The billets are processed and formed into the required shape, which is then welded or bolted to the tank shell to create a solid foundation for the storage tank. In conclusion, steel billets play a crucial role in the manufacturing of storage tanks by providing the necessary raw material for building the tank structure. Through various processes, the billets are transformed into steel plates and sheets, which are then shaped into the tank shell and base, ensuring the tank's strength and durability.

- Q: What are the cost implications of using steel billets in manufacturing?

- Using steel billets in manufacturing can have several cost implications. First and foremost, the cost of steel billets themselves needs to be considered. The price of steel billets can vary depending on factors such as market demand, availability, and the grade of steel used. Therefore, fluctuations in steel prices can directly impact the cost of manufacturing. Additionally, the cost of transportation and logistics needs to be taken into account. Steel billets are heavy and bulky, requiring specialized handling and transportation methods. This can result in higher shipping costs, especially if the manufacturing facility is located far away from the source of steel billets. Furthermore, the cost of processing and shaping steel billets into the desired form for manufacturing needs to be considered. This includes expenses associated with cutting, welding, forging, and any other necessary fabrication processes. The complexity of these processes and the required machinery can have a significant impact on the overall cost of using steel billets. Another cost implication is related to the quality of steel billets. Inferior quality billets can lead to lower product quality and higher rejection rates, resulting in increased manufacturing costs. Therefore, it is important to source steel billets from reputable suppliers to ensure consistent quality and minimize the risk of defects. In terms of long-term costs, the durability and strength of steel make it an attractive choice for manufacturing. Steel is known for its longevity and resistance to wear and tear, reducing the need for frequent replacements and repairs. This can result in long-term cost savings for manufacturers. Lastly, it is essential to consider the environmental and sustainability aspects associated with using steel billets. Steel production is energy-intensive and can have a significant carbon footprint. Increasingly, manufacturers are being held accountable for their environmental impact, which can lead to additional costs in terms of compliance with regulations or implementing sustainable practices. In summary, the cost implications of using steel billets in manufacturing involve the price of the billets themselves, transportation costs, processing expenses, quality considerations, long-term durability, and sustainability factors. Careful analysis of these cost factors is crucial for manufacturers to make informed decisions and optimize their manufacturing processes.

- Q: How are steel billets reheated before rolling or forging?

- Steel billets are reheated before rolling or forging by passing them through a furnace or a reheating furnace, which raises their temperature to a specific range. This process, known as billet reheating, is crucial as it improves the billets' malleability, making them easier to shape and work with during the subsequent rolling or forging operations.

- Q: What are the different methods of steel billet surface treatment?

- There are several methods of steel billet surface treatment that are commonly used in the industry. These methods aim to enhance the surface properties of the steel billets, such as improving corrosion resistance, increasing hardness, and improving aesthetics. Some of the most common methods of steel billet surface treatment are: 1. Pickling and Passivation: This process involves the removal of impurities and oxide layers from the steel surface using acid solutions. After pickling, the steel is passivated to create a protective layer that prevents future corrosion. 2. Shot Blasting: Shot blasting is a mechanical surface treatment method that involves the use of high-speed steel shots or grits to bombard the surface of the billets. This process removes scale, rust, and other contaminants, resulting in a clean and uniform surface. 3. Hot-Dip Galvanizing: In this process, the steel billets are immersed in a bath of molten zinc, which forms a protective coating on the surface. This method provides excellent corrosion protection, making it suitable for outdoor applications. 4. Electroplating: Electroplating involves the deposition of a thin layer of metal, such as chrome or nickel, onto the steel surface using an electric current. This method improves the appearance of the steel, enhances corrosion resistance, and can also provide better wear resistance. 5. Powder Coating: Powder coating is a popular method of surface treatment, especially for aesthetic purposes. It involves applying a dry powder onto the steel surface and then curing it through heat, resulting in a durable and attractive finish. 6. Painting: Painting is another common method used for surface treatment. The steel surface is first cleaned and primed before applying a suitable paint system. This method not only enhances the appearance but also provides protection against corrosion and environmental factors. 7. Nitriding: Nitriding is a heat treatment process that involves the diffusion of nitrogen into the steel surface. This method improves the hardness, wear resistance, and fatigue strength of the billets. These are just a few of the various methods of steel billet surface treatment available. The choice of method depends on the specific requirements of the application, desired properties, and budget considerations.

- Q: How do steel billets contribute to the manufacturing of sports equipment?

- The manufacturing of sports equipment benefits greatly from the use of steel billets. Firstly, steel billets serve as the primary material for the production of steel bars and rods. These bars and rods are then utilized to create the framework and structure of sports equipment, including golf clubs, tennis rackets, and hockey sticks. The exceptional strength and durability of steel make it the perfect material for these applications, as it can withstand the intense impact forces and stresses that occur during sports activities. Furthermore, steel billets are also employed in the manufacturing of various components for sports equipment, such as weights, dumbbells, and barbells. These components necessitate a material with high density that can handle heavy loads, and steel provides the necessary strength and stability. Additionally, steel billets find use in the production of accessories for sports equipment, such as ball bearings, springs, and fasteners. Despite their small size, these components play a vital role in the overall performance and functionality of sports equipment. Steel's exceptional resistance to corrosion and its ability to endure extreme conditions make it the preferred choice, ensuring long-lasting and reliable performance. Moreover, steel billets enable the production of high-quality and precision-made parts for sports equipment. Steel's malleability and formability allow it to be shaped into various intricate designs and configurations, guaranteeing that sports equipment meets the specific requirements of athletes and performs optimally. In conclusion, steel billets are a crucial element in the manufacturing of sports equipment. Their strength, durability, versatility, and formability make them the ideal material for producing frames, components, and accessories that enhance the performance and longevity of sports equipment.

- Q: What are the different sizes and shapes of steel billets?

- Steel billets come in various sizes and shapes, including square, rectangular, and round. The sizes can range from small billets measuring a few inches to larger ones measuring several feet in length and width. The specific size and shape of a steel billet depend on its intended use and manufacturing requirements.

- Q: How are steel billets used in the manufacturing of pressure vessel components?

- Steel billets are a crucial raw material in the manufacturing process of pressure vessel components. Pressure vessels are containers designed to hold gases or liquids at a significantly higher or lower pressure than the surrounding environment. These components are widely used in various industries such as oil and gas, chemical, and power generation. Steel billets, which are semi-finished products with a square or round cross-section, serve as the starting point for the production of pressure vessel components. They are typically made from carbon or alloy steel and undergo several manufacturing processes to transform them into the final product. The first step in the manufacturing process involves heating the steel billets to a specific temperature to make them more malleable. This process is known as hot working or forging. The heated billets are then subjected to pressure, either through hammering or rolling, to shape them into the desired form. This process helps to refine the structure of the steel and improve its mechanical properties. After the initial shaping process, the billets are further processed through a series of machining operations. This includes cutting, drilling, and milling to create the necessary features and dimensions required for pressure vessel components such as shells, heads, nozzles, and flanges. These machining operations ensure that the components meet the precise specifications and tolerances required for safe and efficient operation. Additionally, the steel billets may undergo heat treatment processes such as annealing, quenching, and tempering to further enhance their mechanical properties. Heat treatment helps to improve the strength, hardness, and durability of the steel, making it suitable for withstanding high pressures and corrosive environments. Once the pressure vessel components are machined and heat-treated, they undergo rigorous quality control inspections to ensure they meet the required standards and specifications. This includes non-destructive testing methods such as ultrasonic testing, radiographic testing, and liquid penetrant testing to detect any potential defects or flaws. In summary, steel billets play a crucial role in the manufacturing of pressure vessel components. They are transformed through hot working, machining, and heat treatment processes to create the final products. By using high-quality steel billets and employing stringent quality control measures, manufacturers can produce pressure vessel components that are safe, reliable, and capable of withstanding the demanding conditions they are designed for.

- Q: What are the different types of steel billet rolling techniques?

- There are several different types of steel billet rolling techniques used in the manufacturing process. These techniques are employed to shape the steel into desired forms and dimensions. Some of the commonly used techniques include: 1. Hot rolling: This is the most widely used technique where the steel billet is heated to high temperatures and then passed through a series of rolling mills. The hot rolling process helps in reducing the thickness and increasing the length of the steel billet. 2. Cold rolling: In this technique, the steel billet is rolled at room temperature. It is used to produce steel with a smooth surface finish and precise dimensions. Cold rolling is often used for producing steel sheets, strips, and bars. 3. Ring rolling: This technique is used to produce seamless rings of steel. The steel billet is heated and then rolled between two rotating rolls, which gradually shape the billet into a ring. Ring rolling is commonly used in the production of bearings, gears, and flanges. 4. Continuous casting and rolling: This technique involves the continuous casting of molten steel into billets, which are then directly rolled into desired shapes. Continuous casting and rolling eliminate the need for separate casting and rolling processes, making it a more efficient and cost-effective technique. 5. Cross-rolling: Cross-rolling is used to produce steel billets with non-uniform cross-sections. The billet is rolled between two rolls that have different profiles, resulting in a billet with a desired shape. 6. Skew rolling: Skew rolling is a technique used to produce steel balls used in various industries, such as mining and cement production. The steel billet is rolled between two rotating rolls at an angle, which creates a helical motion and forms the ball shape. These are just a few examples of the different types of steel billet rolling techniques. Each technique has its own advantages and is used based on the desired final product and manufacturing requirements.

Send your message to us

Hot Rolled Square Steel Billet 3SP Standard 115mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords