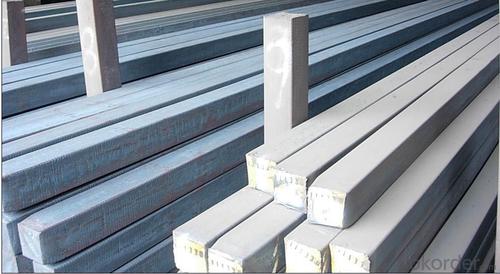

Hot Rolled Square Steel Billet 3SP Standard 110mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Hot Rolled Square Steel Billet 3SP Standard 110mm

Description of Hot Rolled Square Steel Billet 3SP Standard 110mm

PPGI is made by cold rolled steel sheet and galvanized steel sheets as baseplate, through the surface pretreatment (degreasing, cleaning, chemical conversion processing), coated by the method of continuous coatings (roller coating method),

and after roasting and cooling. Zinc coating: Z60, Z80, Z100, Z120, Z180, Z275, G30, G60, G90

Alu-zinc coating: AZ60, AZ80, AZ100, AZ120, AZ180, G30, G60, G90

Main Feature of Hot Rolled Square Steel Billet 3SP Standard 110mm

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve.

Applications of Hot Rolled Square Steel Billet 3SP Standard 110mm

1) Automotive bodies: filters, fuel tanks, etc.

2) Construction materials: roofings, welding pipes,

3) Electric and electronic appliances: computer cans, etc.

4) Steel cans: containers, etc.

5) Steel furniture: washing machines, refrigerators, microwaves, etc.

6) Drums

7) Office equipment: printer, recorders, etc.

8) Motors and transformers

Specifications of Hot Rolled Square Steel Billet 3SP Standard 110mm

| Classified symbol | Yield Point Minimum N/mm2 | Tensile Strength Minimum | Elongation Minimum % | Application | ||||

| N/mm2 | Nominal Thickness mm (t) | |||||||

| JIS | Yogic | 0.25-0.4 | 0.4-0.6 | 0.6-1.0 | 1.0-1.6 | |||

| G3312 | specification | |||||||

| CGCC | CGCC | -205 | -270 | -20 | -21 | -24 | -24 | Commercial |

| CGCD | CGCD | --- | 270 | --- | 27 | 31 | 32 | Drawing |

| --- | CG340 | 245 | 340 | 20 | 20 | 20 | 20 | Structural |

| CGC400 | CG400 | 295 | 400 | 16 | 17 | 18 | 18 | Structural |

| CGC440 | CG440 | 335 | 440 | 14 | 15 | 16 | 18 | Structural |

| CGC490 | CG490 | 365 | 490 | 12 | 13 | 14 | 16 | Structural |

| CGC570 | CG570 | 560 | 570 | --- | --- | --- | --- | Structural |

| ASTM Designation | Yield Point Minimum | Tensile Strength Minimum | Elongation Minimum % | Application | Q/BQB 445-2004(China standard) | ASM A653/A653M | JISG 3312 | |

| ksi(MPa) | ksi(MPa) | TDC51D+Z | (CS TYPE A+Z) | CGCC | ||||

| A653(M)-99 CS TYPE A,B,C | --- | --- | --- | Commercial | TDC52D+Z | CGCD | ||

| A653(M)-99 FS | --- | --- | --- | Lock Forming | TS250GD+Z | (G250+Z) | - | |

| A653(M)-99 DS | --- | --- | --- | Drawing | TS300GS+Z | (G300+Z) | CGC 400 | |

| A653(M)-99 SS Grade33(230) | 33(230) | 45(310) | 20 | Structural | TS350GD+Z | (G350+Z) | CGC490 | |

| A653(M)-99 SS Grade37(255) | 37(255) | 52(360) | 18 | Structural | TS550GD+Z | (G550+Z) | CGC570 | |

| A653(M)-99 SS Grade40(275) | 40(275) | 55(380) | 16 | Structural | ||||

| A653(M)-99 SS Grade50(345) | 50(345) | 65(450) | 12 | Structural | ||||

| A653(M)-99 SS Grade80(550) | 80(550) | 82(570) | --- | Structural | ||||

FAQ of Hot Rolled Square Steel Billet 3SP Standard 110mm

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

1, ISO, BV, CE, SGS approved.

2, Competitive price and quality.

3, Efficient service team online for 24 hours.

4, Smooth production ability(50000tons/month) .

5, quick delivery and standard exporting package.

6, Flexible payment with T/T, L/C, Paypal, Kunlun bank, etc .

- Q: How do steel billets contribute to the infrastructure development?

- The versatility and strength of steel billets make them an essential element in infrastructure development. These solid steel blocks serve as a fundamental raw material for building construction, bridge construction, and other infrastructure projects. An important way in which steel billets contribute to infrastructure development is through the production of reinforced concrete. Steel rebars, which are made from steel billets, are embedded in concrete to enhance its strength and durability. This reinforcement enables structures to withstand external forces, ensuring their long-term stability. Furthermore, steel billets are also utilized in the production of structural steel sections like beams, columns, and trusses. These components are crucial for constructing diverse types of infrastructure, including high-rise buildings and bridges. The incorporation of steel in such applications provides exceptional load-bearing capacity, enabling the construction of large and intricate structures. Steel billets also play a significant role in the manufacturing of pipes, which are a vital part of infrastructure systems such as water supply, sewage, and gas pipelines. Due to its strength and resistance to corrosion, steel is an ideal material for these applications, guaranteeing the integrity and longevity of the infrastructure network. Another noteworthy contribution of steel billets to infrastructure development is their use in the manufacturing of heavy machinery and equipment used in construction projects. Steel billets are utilized in constructing the frames and other structural components of machinery, ranging from cranes to excavators. This ensures that these machines possess the necessary strength and reliability for effective construction work. In conclusion, steel billets are indispensable for infrastructure development as they provide the required strength and durability for various construction applications. Whether it involves reinforcing concrete, manufacturing structural components, or constructing heavy machinery, steel billets play a crucial role in creating resilient and long-lasting infrastructure.

- Q: How are steel billets used in the manufacturing of machinery?

- Due to their versatility and strength, steel billets play a crucial role in the production of machinery. These cylindrical metal bars, typically made from carbon or alloy steel, serve as the raw material for various machine parts and components. One common application of steel billets in machinery manufacturing involves using them to create machine frames and structures. The billets are heated and then hot-rolled or forged to achieve the desired shape. This ensures that the final product possesses the necessary strength and durability to withstand the mechanical stresses it will encounter during operation. Moreover, steel billets are utilized in the fabrication of machine components like gears, shafts, and axles. These parts require high tensile strength and resistance to wear and deformation, making steel billets the ideal material choice. Machining or forging the billets into the desired shape guarantees precise dimensions and tolerances are met. Furthermore, steel billets find application in the production of machine tools, which are vital for shaping and machining various materials. By using steel billets as the base material, machine tools can effectively handle heavy loads, provide stability, and ensure precision in the manufacturing processes. In conclusion, steel billets are essential in machinery manufacturing due to their strength, durability, and versatility. They enable the production of machine frames, components, and tools that can effectively perform their intended functions. The ability to shape, machine, and forge steel billets into various forms allows for the creation of high-quality machinery.

- Q: Refinery carbon 3 is propane, then carbon four carbon five is what name ah?.What are they used for?

- This is isomericCarbon four is butane, n-butane and isobutaneCarbon five is pentane pentane. ISO pentane. PentaneThey are intermediates in refining

- Q: What are the potential applications of steel billets in the chemical industry?

- Due to their unique properties and versatility, steel billets have numerous potential applications in the chemical industry. One primary use of steel billets in the chemical industry involves their utilization in the production of various types of equipment and machinery. Steel billets can be shaped and forged into different forms, such as pipes, tanks, valves, and fittings, which are crucial for the handling and storage of chemicals. These components need to withstand harsh conditions, including high temperatures, pressures, and corrosive environments, thereby making steel billets an ideal material choice. Additionally, steel billets can be employed in the construction of chemical plants and facilities. They provide exceptional structural support, ensuring the stability and integrity of the buildings. Steel billets are often used in fabricating beams, columns, and other load-bearing elements, providing strength and durability to withstand the chemical processes occurring within the plant. Another potential application of steel billets in the chemical industry pertains to the manufacturing of reaction vessels and reactors. These vessels are utilized for chemical reactions, such as synthesis, distillation, and purification processes. Steel billets can be machined and formed into the desired shape, allowing for the creation of robust and reliable vessels that can handle the high pressures and temperatures often required in chemical reactions. Furthermore, steel billets can be utilized in the production of catalysts used in various chemical processes. Catalysts are substances that expedite chemical reactions without being consumed in the process. Steel billets can serve as a base material for catalysts, providing a stable and durable support structure for the active catalytic components. Moreover, steel billets can be employed in the construction of storage tanks and containers for the transportation and storage of chemicals. Steel billets offer exceptional resistance to corrosion and can be easily welded and fabricated into large containers, ensuring the safe and secure storage of hazardous chemicals. In summary, steel billets possess vast potential applications in the chemical industry. Their strength, durability, and resistance to corrosion make them indispensable materials for various chemical processes and operations, encompassing equipment fabrication, construction projects, catalyst manufacturing, and storage solutions.

- Q: What are the different types of steel billet shearing techniques?

- The industry employs various steel billet shearing techniques, each tailored to meet specific cutting requirements and achieve desired final products. Commonly used techniques include: 1. Guillotine Shearing: This method utilizes a guillotine-style shear blade that descends onto the steel billet, exerting a shearing force to cut through the material. 2. Circular Shearing: A circular shear blade is employed in this technique. As the blade spins at high speed, it exerts a cutting force upon contact with the billet. 3. Band Saw Shearing: This method employs a continuous loop of teeth on a band saw blade to cut through the steel billet. The blade moves in a continuous motion, slicing through the billet as it progresses. 4. Rotary Shearing: This technique involves the use of a rotary shear, equipped with rotating blades that grip the billet and cut through it as it advances through the machine. 5. Flame Cutting: Also referred to as oxyfuel cutting, this technique employs a high-temperature flame to melt and sever the steel billet. By directing a stream of oxygen onto the billet, a chemical reaction is initiated, facilitating the cutting process. 6. Plasma Cutting: Plasma cutting utilizes a high-velocity jet of ionized gas to melt and cut through the steel billet. The gas is heated to an exceptionally high temperature and directed onto the billet, resulting in a precise and clean cut. Each of these steel billet shearing techniques possesses distinct advantages and limitations, dependent on factors such as billet size, thickness, required cutting accuracy, and desired cutting speed.

- Q: How do steel billets contribute to the manufacturing of automotive components?

- Steel billets are the starting point for the manufacturing of automotive components as they are heated and shaped into various forms such as rods, bars, and sheets. These billets are strong, durable, and can be easily molded into the desired shape, making them ideal for producing structural automotive parts like engine blocks, chassis, and suspension components. Additionally, steel billets provide the necessary strength and stability required to withstand the harsh conditions and loads experienced by automotive components, ensuring the overall safety and reliability of vehicles.

- Q: How are steel billets used in the production of automotive parts?

- Steel billets are commonly used in the production of automotive parts as they serve as the raw material for forging, rolling, or extruding processes. These billets are heated and shaped into various forms such as rods, bars, or sheets to create components like engine parts, suspension systems, and body frames. The high strength and durability of steel make it an ideal choice for manufacturing automotive parts, ensuring safety and performance in vehicles.

- Q: How do steel billets contribute to the renewable energy sector?

- Steel billets play a crucial role in the renewable energy sector by supporting the manufacturing of various renewable energy technologies. One of the main ways steel billets contribute to this sector is by providing the necessary raw material for the construction of wind turbines. Wind turbines require strong and durable structures to withstand the harsh environmental conditions, and steel billets serve as the primary material for manufacturing their towers and foundations. Moreover, steel billets are used in the production of solar panels. These panels are made up of photovoltaic cells that convert sunlight into electricity. Steel billets are used to create the frames and mounting structures that provide support and stability to the solar panels, ensuring their proper functioning and longevity. Additionally, steel billets are used in the manufacturing of hydroelectric power equipment. Hydroelectric power is generated by converting the kinetic energy of flowing or falling water into electricity. The turbines used in hydroelectric power plants are often made from steel billets due to their high strength and resistance to corrosion. The billets are used to create the turbine blades, shafts, and other components that help generate electricity from water. Furthermore, steel billets are essential for the manufacturing of energy storage systems, such as batteries. Renewable energy sources like wind and solar are intermittent, meaning they are not constantly available. Energy storage systems help store excess energy generated during peak times and release it when the demand is high. Steel billets are used in the construction of battery casings and structural components, ensuring the safety and durability of these storage systems. In conclusion, steel billets contribute significantly to the renewable energy sector by providing the essential raw material for the construction of wind turbines, solar panels, hydroelectric power equipment, and energy storage systems. Their strength, durability, and resistance to corrosion make them a vital component in the manufacturing of various renewable energy technologies, ultimately helping to accelerate the transition towards a more sustainable and greener future.

- Q: How are steel billets used in the production of industrial furnaces?

- Steel billets serve as a vital element in the manufacturing of industrial furnaces, being a key component required for the production of different furnace parts. To start off, the furnace shell or casing, which is responsible for providing structural integrity and containment, is fabricated using steel billets. These billets are shaped and welded together, forming a robust outer shell capable of enduring the high temperatures and harsh conditions inside the furnace. Additionally, steel billets are utilized in the creation of furnace doors and access panels. These components need to possess strength and resistance to deformation caused by the intense heat generated within the furnace. By employing steel billets, manufacturers can ensure that the doors and access panels are easily operable while maintaining their structural integrity over time. Furthermore, steel billets are also employed in the construction of furnace grates and supports. These components play a crucial role in holding and supporting the materials undergoing heating inside the furnace. By utilizing steel billets, manufacturers are able to fabricate sturdy and heat-resistant supports capable of withstanding heavy loads and high temperatures for extended periods. Moreover, steel billets are frequently employed in the fabrication of heat exchangers within industrial furnaces. Heat exchangers are vital for transferring heat from the combustion chamber to the materials being processed. The use of steel billets ensures that the heat exchangers possess exceptional thermal conductivity and can endure the corrosive effects of the furnace environment. Overall, steel billets have a critical function in the production of industrial furnaces, providing the necessary strength, durability, and resistance to heat required for the various components. Without steel billets, the manufacturing of furnaces capable of withstanding the extreme conditions encountered in industrial processes would be quite challenging.

- Q: How does the composition of steel affect the properties of steel billets?

- The composition of steel, including the ratios of different elements and the impurities present, significantly influences the properties of steel billets. For instance, the amount of carbon in steel affects its strength and hardness, with higher carbon content resulting in harder and stronger steel. Alloying elements like chromium, nickel, and molybdenum can be added to enhance specific properties such as corrosion resistance, heat resistance, or toughness. Furthermore, impurities like sulfur and phosphorus can negatively impact the ductility and weldability of steel. Hence, the composition plays a crucial role in determining the overall quality and performance of steel billets.

Send your message to us

Hot Rolled Square Steel Billet 3SP Standard 110mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords