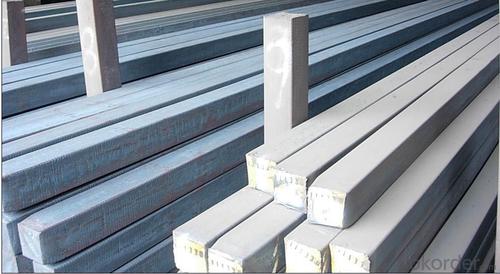

Hot Rolled Square Steel Billet 3SP Standard 130mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Hot Rolled Square Steel Billet 3SP Standard 130mm

Description of Hot Rolled Square Steel Billet 3SP Standard 130mm

PPGI is made by cold rolled steel sheet and galvanized steel sheets as baseplate, through the surface pretreatment (degreasing, cleaning, chemical conversion processing), coated by the method of continuous coatings (roller coating method),

and after roasting and cooling. Zinc coating: Z60, Z80, Z100, Z120, Z180, Z275, G30, G60, G90

Alu-zinc coating: AZ60, AZ80, AZ100, AZ120, AZ180, G30, G60, G90

Main Feature of Hot Rolled Square Steel Billet 3SP Standard 130mm

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve.

Applications of Hot Rolled Square Steel Billet 3SP Standard 130mm

1) Automotive bodies: filters, fuel tanks, etc.

2) Construction materials: roofings, welding pipes,

3) Electric and electronic appliances: computer cans, etc.

4) Steel cans: containers, etc.

5) Steel furniture: washing machines, refrigerators, microwaves, etc.

6) Drums

7) Office equipment: printer, recorders, etc.

8) Motors and transformers

Specifications of Hot Rolled Square Steel Billet 3SP Standard 130mm

| Classified symbol | Yield Point Minimum N/mm2 | Tensile Strength Minimum | Elongation Minimum % | Application | ||||

| N/mm2 | Nominal Thickness mm (t) | |||||||

| JIS | Yogic | 0.25-0.4 | 0.4-0.6 | 0.6-1.0 | 1.0-1.6 | |||

| G3312 | specification | |||||||

| CGCC | CGCC | -205 | -270 | -20 | -21 | -24 | -24 | Commercial |

| CGCD | CGCD | --- | 270 | --- | 27 | 31 | 32 | Drawing |

| --- | CG340 | 245 | 340 | 20 | 20 | 20 | 20 | Structural |

| CGC400 | CG400 | 295 | 400 | 16 | 17 | 18 | 18 | Structural |

| CGC440 | CG440 | 335 | 440 | 14 | 15 | 16 | 18 | Structural |

| CGC490 | CG490 | 365 | 490 | 12 | 13 | 14 | 16 | Structural |

| CGC570 | CG570 | 560 | 570 | --- | --- | --- | --- | Structural |

| ASTM Designation | Yield Point Minimum | Tensile Strength Minimum | Elongation Minimum % | Application | Q/BQB 445-2004(China standard) | ASM A653/A653M | JISG 3312 | |

| ksi(MPa) | ksi(MPa) | TDC51D+Z | (CS TYPE A+Z) | CGCC | ||||

| A653(M)-99 CS TYPE A,B,C | --- | --- | --- | Commercial | TDC52D+Z | CGCD | ||

| A653(M)-99 FS | --- | --- | --- | Lock Forming | TS250GD+Z | (G250+Z) | - | |

| A653(M)-99 DS | --- | --- | --- | Drawing | TS300GS+Z | (G300+Z) | CGC 400 | |

| A653(M)-99 SS Grade33(230) | 33(230) | 45(310) | 20 | Structural | TS350GD+Z | (G350+Z) | CGC490 | |

| A653(M)-99 SS Grade37(255) | 37(255) | 52(360) | 18 | Structural | TS550GD+Z | (G550+Z) | CGC570 | |

| A653(M)-99 SS Grade40(275) | 40(275) | 55(380) | 16 | Structural | ||||

| A653(M)-99 SS Grade50(345) | 50(345) | 65(450) | 12 | Structural | ||||

| A653(M)-99 SS Grade80(550) | 80(550) | 82(570) | --- | Structural | ||||

FAQ of Hot Rolled Square Steel Billet 3SP Standard 130mm

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

1, ISO, BV, CE, SGS approved.

2, Competitive price and quality.

3, Efficient service team online for 24 hours.

4, Smooth production ability(50000tons/month) .

5, quick delivery and standard exporting package.

6, Flexible payment with T/T, L/C, Paypal, Kunlun bank, etc.

- Q: How are steel billets used in the manufacturing of fasteners and fittings?

- Steel billets are used in the manufacturing of fasteners and fittings as they serve as the raw material from which these components are produced. These billets are heated and then shaped using various processes such as forging, extrusion, or machining to create the desired shape and size of the fasteners and fittings. The steel billets provide the necessary strength and durability required for these components to withstand the forces and loads they will encounter in their applications.

- Q: How do steel billets contribute to the manufacturing of water and wastewater treatment equipment?

- Steel billets are used in the manufacturing of water and wastewater treatment equipment as they serve as the raw material for various components such as pipes, tanks, and structural supports. These billets are melted and shaped into the required forms, ensuring the durability and strength of the equipment. Additionally, steel billets can be further processed to create corrosion-resistant coatings, ensuring the longevity and reliability of the equipment in harsh water and wastewater environments.

- Q: What are the different types of tests conducted on steel billets?

- Steel billets undergo various tests to assess their quality and suitability for different applications. These tests play a crucial role in determining the mechanical properties, chemical composition, and overall integrity of the billets. 1. Analyzing Chemical Composition: The chemical composition of the steel billets is examined to ensure compliance with specified standards and requirements. This analysis measures the levels of carbon, manganese, silicon, sulfur, and phosphorus, among other elements. 2. Tensile Strength Evaluation: The tensile test assesses the ability of the steel billets to withstand pulling forces without breaking. It measures parameters such as tensile strength, yield strength, and elongation. 3. Determining Hardness: The hardness test evaluates the steel billets' resistance to wear, deformation, and penetration. It involves different hardness tests such as Brinell, Rockwell, and Vickers. 4. Assessing Impact Resistance: The impact test measures the toughness and capacity of the steel billets to absorb energy under sudden loading or impact conditions. It helps determine their resistance to fracture and cracking. 5. Ultrasonic Inspection: This non-destructive test employs high-frequency sound waves to detect internal flaws or defects in the steel billets. It is a valuable method for identifying cracks, voids, and inclusions that may compromise the billets' structural integrity. 6. Verifying Dimensions: The dimensional inspection ensures that the steel billets meet the specified dimensional requirements, including length, width, and thickness. This verification confirms their suitability for intended applications and subsequent manufacturing processes. 7. Macroscopic Examination: This visual inspection involves magnified examination of the steel billets' surface and internal structure. It helps identify visible defects like cracks, porosity, segregation, or irregularities. 8. Microscopic Examination: By using a microscope, the microscopic examination analyzes the microstructure of the steel billets. It provides insights into grain size, presence of phases, and any abnormalities that may affect the steel's properties. Collectively, these tests guarantee that the steel billets meet the required quality standards and possess the necessary mechanical properties for their intended applications. They ensure the safety, reliability, and performance of steel billets in industries like construction, automotive, aerospace, and manufacturing.

- Q: Can steel billets be used in the production of consumer electronics?

- No, steel billets are not typically used in the production of consumer electronics. Steel billets are semi-finished steel products that are typically used as raw material in the manufacturing of other steel products, such as bars, rods, and pipes. Consumer electronics, on the other hand, are typically made using a variety of materials, including plastics, metals like aluminum and copper, and electronic components such as circuit boards and semiconductors. While steel may be used in some components of consumer electronics, such as the casing or frame, it is usually in a more processed form, such as sheet metal or extruded profiles, rather than steel billets.

- Q: 20 what is the difference between manganese silicon steel billet and Q235 billet?

- In brief, the ingredients are different and the uses are different.

- Q: What are the key factors driving the demand for steel billets?

- The demand for steel billets is influenced by several key factors. Firstly, the construction industry plays a crucial role in driving this demand. Steel is widely utilized in construction projects for various purposes, including structural framing, reinforcement, and support systems. With the continuous growth of urbanization and increasing infrastructure projects, the demand for steel billets also rises. Additionally, the automotive industry significantly impacts the demand for steel billets. Steel is an essential material in the manufacturing of automobiles, such as car bodies, chassis, and engine components. As the global automotive industry expands and consumer demand for vehicles increases, the demand for steel billets also rises accordingly. Moreover, the energy sector contributes to the demand for steel billets, particularly in the production of oil and gas pipelines. Steel billets are used in the manufacturing of seamless pipes, which are vital for the transportation of oil and gas over long distances. As the demand for energy continues to grow, there is a corresponding need for steel billets to support pipeline construction. Furthermore, the manufacturing and machinery industries heavily rely on steel billets. Steel is a fundamental material used in various manufacturing processes, from industrial machinery to consumer products. As these industries grow and evolve, the demand for steel billets remains steady. Lastly, the demand for steel billets is significantly influenced by global economic growth and industrialization in emerging markets. Countries with rapidly developing economies, such as China and India, are major consumers of steel billets as they undergo massive infrastructure projects and industrial expansion. In conclusion, the demand for steel billets is primarily driven by the construction industry, automotive sector, energy sector, manufacturing industry, and global economic growth. These factors collectively contribute to the sustained and growing demand for steel billets in the market.

- Q: What are the main disadvantages of using steel billets?

- There are several disadvantages associated with using steel billets in various industries. Firstly, one of the main drawbacks of steel billets is their high cost. Steel billets require a complex manufacturing process, involving melting and casting steel, which can be expensive. This cost is then transferred to the end product, making it less affordable for consumers. Secondly, steel billets tend to be heavy and bulky, making transportation and handling difficult. The weight and size of steel billets add to the overall logistical challenges in the supply chain, increasing costs and potentially causing delays. Another disadvantage is the limited availability of steel billets. Steel production requires a significant amount of resources and energy, and the availability of raw materials can be limited, leading to potential supply chain disruptions. This scarcity can negatively impact industries that rely heavily on steel billets for their operations. Furthermore, steel billets have limited shape flexibility. They are typically produced in standardized sizes and shapes, making it difficult to customize them for specific design requirements. This lack of flexibility can be a significant disadvantage in industries that require intricate and unique shapes for their products. Moreover, steel billets are prone to corrosion if not properly treated. The exposure to moisture and certain environments can cause rust and degradation, reducing the lifespan and durability of products made from steel billets. Regular maintenance and anti-corrosion treatments are essential to mitigate this disadvantage. Lastly, the production of steel billets has a significant environmental impact. The manufacturing process emits greenhouse gases and consumes large amounts of energy and water. These environmental concerns have led to increased scrutiny and regulations on steel production, adding additional costs and complexities to using steel billets. In conclusion, while steel billets have their advantages in terms of strength and durability, they also come with several drawbacks. These include high costs, transportation challenges, limited availability, lack of shape flexibility, susceptibility to corrosion, and environmental impact. It is crucial for industries to carefully consider these disadvantages when evaluating the use of steel billets in their operations.

- Q: What are the potential applications of steel billets in the transportation sector?

- Steel billets have a wide range of potential applications in the transportation sector due to their strength, durability, and versatility. One of the primary uses of steel billets in transportation is for the manufacturing of various vehicle components. These billets can be used to produce engine parts, suspension systems, axles, and other critical components that require high strength and resistance to wear and tear. Additionally, steel billets can be utilized in the construction of railway tracks, bridges, and tunnels. The high tensile strength of steel makes it an ideal material for these infrastructure projects, as it can withstand heavy loads and provide long-lasting performance. Steel billets can also be employed in the manufacturing of shipbuilding components, such as hulls, propellers, and deck structures, as they offer excellent corrosion resistance and structural integrity in marine environments. Furthermore, steel billets can be used in the production of various types of transportation equipment, including trailers, trucks, and buses. The strength and durability of steel make it an ideal material for constructing the chassis and frames of these vehicles, ensuring their safety and longevity. In the automotive industry, steel billets are commonly used for producing car bodies and frames. The lightweight yet robust characteristics of steel make it a preferred choice for improving fuel efficiency and crashworthiness in vehicles. Moreover, steel billets can be shaped into intricate designs, enabling manufacturers to create aesthetically pleasing and aerodynamic vehicle structures. In summary, steel billets have numerous potential applications in the transportation sector, ranging from vehicle components to infrastructure projects. Their strength, durability, and versatility make them a vital material for various transportation applications, ensuring safety, reliability, and longevity in the industry.

- Q: What are the potential applications of steel billets in the aerospace aftermarket?

- Steel billets have various potential applications in the aerospace aftermarket. These include the manufacturing of specialized components and parts for aircraft engines, landing gears, and structural frameworks. Steel billets can also be used for repairs and replacements of damaged or worn-out aerospace components, ensuring the continued safe and efficient operation of aircraft.

- Q: What is the difference between steel billets and steel bars?

- Steel billets and steel bars, two semi-finished products made from steel, exhibit distinct dissimilarities. To begin with, steel billets possess larger dimensions compared to steel bars. Billets typically assume a square or rectangular form with a cross-sectional area ranging from 36 to 216 square inches. Their production commonly involves the continuous casting process, which entails pouring molten steel into molds, followed by cooling and solidification. Billets function as the initial material for various steel products, including bars, rods, and wire. Conversely, steel bars display smaller proportions and adhere to more standardized shapes. Their configuration can be round, square, hexagonal, or flat, contingent upon their intended application. The production of steel bars chiefly involves the hot rolling method, wherein billets undergo heating and are subsequently passed through a series of rolling mills to achieve the desired dimensions and shape. Bars frequently find use in construction, manufacturing, and other industries that prioritize strength and durability. Another disparity between steel billets and steel bars resides in their surface finish. The casting process renders steel billets with a rough mill-scale surface. In contrast, steel bars possess a smoother surface finish, achieved through hot rolling and subsequent finishing procedures such as peeling, grinding, or polishing. Moreover, steel billets primarily serve as raw materials for further processing, while steel bars represent the final product that can be directly employed in diverse applications. Steel bars commonly feature in construction projects as reinforcement for concrete structures, in machinery and tool production, as well as in the manufacturing of automotive parts, among numerous other industrial applications. In conclusion, steel billets and steel bars differ in terms of size, shape, surface finish, and purpose. Billets are larger, rougher, and act as the starting point for various steel products, whereas bars are smaller, boast a smoother surface finish, and emerge as the final product utilized across a wide array of applications.

Send your message to us

Hot Rolled Square Steel Billet 3SP Standard 130mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords