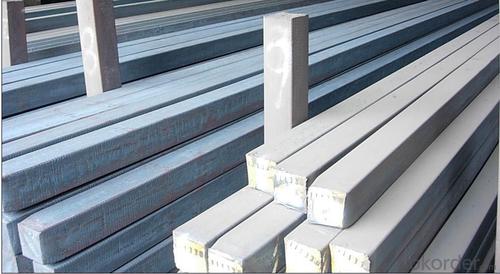

Hot Rolled Steel Billet 3SP Standard 130mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Hot Rolled Steel Billet 3SP Standard 130mm

Description of Hot Rolled Steel Billet 3SP Standard 130mm

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

Main Feature of Hot Rolled Steel Billet 3SP Standard 130mm

1.Corrosion resistance: It mainly depends on the zinc protection. When the zinc being worn,

2. Heat resistance: steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

Applications of Hot Rolled Steel Billet 3SP Standard 130mm

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; gas tank;road sign; etc.

4.Agriculture constructions :barn; etc.RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

5.Others:vending machine; game machine; auto parts spare parts etc.

Specifications of Hot Rolled Steel Billet 3SP Standard 130mm

Product | Hot Rolled Steel Billet 3SP Standard 130mm |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.5-3.0mm |

Width | 700-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled,RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 25MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Hot Rolled Steel Billet 3SP Standard 130mm

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 100 mt for each size each specification. Usually we can offer discount if can buy large QTY once. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

2. How long can we receive the product after ordering?

Our general delivery time is 30 days after confirmation, but so some special orders, we have offer special delivery time

3. How to guarantee the quality of the products?

We have established the international advanced quality management system ,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. What is the payment?

We accept T/T, L/C

- Q: What are the international standards for steel billets?

- The International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) are the primary governing bodies for international steel billet standards. They have developed various standards to guarantee the quality and consistency of steel billets worldwide. ISO 4948-1:2019 outlines the general requirements for steel billets that will be converted into seamless tubes and pipes. It encompasses dimensions, tolerances, surface conditions, and test methods to evaluate the physical and mechanical properties of the billets. By adhering to ISO 4948-1, the billets are ensured to meet the necessary criteria for subsequent tube and pipe manufacturing processes. ASTM A370 serves as the standard test method for the mechanical testing of steel products, including billets. This standard provides guidelines for various mechanical tests such as tension, hardness, and impact tests, which assess the strength, ductility, and toughness of the billets. It guarantees that the billets meet the specified mechanical properties required for their intended applications. Aside from ISO and ASTM standards, there are also regional and national standards that apply to steel billets. For instance, the European Committee for Standardization (CEN) has developed the EN 10025 series of standards that cover the technical delivery conditions for structural steels, including billets. These standards specify the chemical composition, mechanical properties, and testing requirements for the billets used in construction and other structural applications in Europe. Overall, the international standards for steel billets aim to establish uniformity and quality control in the production and utilization of these materials across various industries and regions. Complying with these standards ensures that steel billets meet the necessary criteria for subsequent processing and application, thereby ensuring safety, reliability, and performance.

- Q: How are steel billets used in the production of electrical transmission towers?

- Steel billets play a crucial role in the manufacturing of electrical transmission towers. These billets are semi-finished steel products that are cast into a specific shape and size. When it comes to transmission towers, steel billets are used as raw material to create the tower structures. The process begins by carefully selecting high-quality steel billets and inspecting them for their chemical composition and physical properties. Once the billets meet the required specifications, they undergo heating and are passed through a series of rolling mills to achieve the desired shape and size of the tower sections. To make the steel billets malleable, they are heated to a specific temperature. This heating process reduces internal stresses and enhances the steel's ductility. The heated billets are then shaped into various sections such as angles, channels, and I-beams by passing them through multiple rolling stands. These sections are further cut into appropriate lengths and welded together to form the framework of the transmission tower. The steel billets provide the necessary strength and structural integrity to withstand the weight of the tower and environmental loads like wind and ice. In addition, the use of steel billets ensures excellent corrosion resistance, as steel is known for its durability and longevity. This is crucial for maintaining the reliability and safety of the power transmission infrastructure. In conclusion, steel billets are vital in the production of electrical transmission towers as they provide the raw material necessary for manufacturing the tower structures. Their strength, durability, and corrosion resistance make them an ideal choice for constructing towers that can support transmission lines and ensure efficient and reliable distribution of electricity.

- Q: What is the role of steel billets in the manufacturing of construction excavators?

- The significance of steel billets in the production of construction excavators cannot be overstated. These semi-finished steel products, shaped like rectangular solids, are vital for creating various components of excavators. An essential characteristic of steel billets is their exceptional strength and durability. The construction industry requires materials that can endure heavy loads, intense pressure, and harsh working conditions. Steel billets possess these qualities, making them perfect for fabricating excavators that can withstand the demanding nature of construction sites. Throughout the manufacturing process, steel billets are heated and formed into different parts of the excavator, such as the mainframe, booms, arms, and buckets. These components necessitate high-strength materials to guarantee structural integrity and longevity. Moreover, steel billets offer the advantage of precise customization and fabrication. Manufacturers can mold and shape the billets into specific sizes and dimensions, tailored to the requirements of different excavator parts. This flexibility ensures a seamless fit of the components, enhancing the overall performance and functionality of the machine. Furthermore, steel billets exhibit excellent weldability. Given the constant stress and movement excavators undergo, welding is a critical process for joining the various components. Steel billets facilitate strong and dependable welds, ensuring the structural soundness of the excavator and its ability to handle heavy-duty tasks. In conclusion, the role of steel billets in the manufacturing of construction excavators is indispensable. Their strength, durability, customizability, and weldability make them the ideal raw material for constructing robust and reliable machines, indispensable for the demanding nature of the construction industry.

- Q: How are steel billets cut into desired lengths?

- Steel billets are typically cut into desired lengths using a process called sawing or shearing. This involves using specialized machinery, such as band saws or circular saws, to cut through the steel billet along the desired length. The saw blades are designed to withstand the hardness of the steel and make precise cuts. This process allows for accurate and efficient production of steel billets in varying lengths as per the requirements of different industries.

- Q: How are steel billets used in the manufacturing of medical devices?

- The manufacturing of medical devices relies on steel billets in multiple ways. Surgical instruments, like scalpels, forceps, and scissors, use steel billets as a raw material. These instruments demand strength, durability, and corrosion resistance, qualities that steel billets possess. Steel billets also find use in the production of implants, such as joint replacements and dental implants. These implants must withstand the body's load and stress, making steel billets an ideal material due to their outstanding mechanical properties. Furthermore, medical equipment like hospital beds, wheelchairs, and surgical tables are manufactured using steel billets. These devices require a robust structure, and steel billets provide the necessary strength and stability. Moreover, steel billets are integral to the manufacturing of medical equipment components, such as brackets, frames, and supports. These components are crucial for the proper functioning and stability of medical devices, and steel billets are often selected for their high machinability and weldability. In summary, steel billets play a vital role as a raw material in the manufacturing of diverse medical devices. Their strength, durability, corrosion resistance, and other mechanical properties make them an excellent choice for producing surgical instruments, implants, medical equipment, and their components.

- Q: What are the main factors affecting the hardenability of alloy steel billets?

- The main factors affecting the hardenability of alloy steel billets include the chemical composition of the alloy, the grain size and distribution, the cooling rate during heat treatment, and the presence of alloying elements such as carbon, manganese, chromium, and molybdenum. These factors determine the ability of the steel to form and retain a hardened structure, thus affecting its overall hardness and strength properties.

- Q: How are steel billets used in the manufacturing of industrial machinery parts?

- Steel billets possess unique properties and versatility, making them indispensable for the production of industrial machinery parts. These semi-finished steel products are typically cast in square or rectangular shapes and serve as the foundational material for critical components like gears, shafts, pistons, and others. To facilitate manipulation and shaping, the first step involves heating the steel billets to a specific temperature. Once heated, they undergo a process known as hot rolling, where they are passed through rollers to decrease their cross-sectional area and increase their length. This not only enhances the steel's strength and durability but also refines its microstructure, resulting in improved mechanical properties. Following hot rolling, further processing takes place through machining operations such as cutting, drilling, milling, and grinding. These operations ensure precise dimensions and specifications required for specific machinery parts, enabling seamless integration into the overall machinery assembly. The high strength, toughness, and resistance to wear and tear of steel billets make them highly sought after in the manufacturing of industrial machinery parts. Their exceptional machinability allows for intricate designs and patterns, ensuring optimal functionality and performance. Additionally, steel billets can be easily welded, enabling the joining of multiple parts to create robust structures. In summary, steel billets play a vital role in the manufacturing of industrial machinery parts. By providing a strong, durable, and versatile starting material, they enable the creation of precise and reliable components essential for the smooth operation of industrial machinery in sectors such as manufacturing, construction, and transportation.

- Q: What are the different types of machining processes used for shaping steel billets?

- Shaping steel billets can be achieved through various machining processes. Below are some of the most commonly employed methods: 1. Turning: By rotating the billet against a cutting tool, material is removed from the outer surface. This technique is frequently utilized to produce cylindrical shapes or eliminate excess material from the billet. 2. Milling: Material is removed from the billet's surface using a rotating cutting tool. This process is suitable for creating flat surfaces, slots, or intricate shapes. 3. Drilling: Holes are created in the billet by employing a rotating cutting tool. This can be accomplished manually or with the aid of a drilling machine. 4. Grinding: An abrasive wheel or belt is employed in grinding to eliminate material from the billet's surface. It is commonly used to achieve a smooth and precise finish. 5. Broaching: Broaching involves the use of a toothed cutting tool called a broach to remove material from the billet. This method is often employed to create internal or external splines, keyways, or other specialized shapes. 6. Sawing: Sawing is a cutting technique that utilizes a saw blade to divide the billet into smaller sections or remove excess material. This can be done manually or with the assistance of a sawing machine. These examples illustrate just a few of the machining processes utilized in shaping steel billets. Each process offers unique advantages and is selected based on the specific requirements of the final product.

- Q: What are the different international trade regulations for steel billets?

- The trade of steel billets is governed by various international trade regulations, each serving different purposes. These regulations are in place to promote fair trade practices, guarantee product quality, and deter unfair competition. Here are some of the key regulations pertaining to steel billets: 1. Tariffs and import duties: To safeguard their domestic steel industries, many countries impose tariffs or import duties on steel billets. These levies differ significantly across nations and may undergo periodic revisions. Importers and exporters must be mindful of these tariffs and factor them into their pricing and cost calculations. 2. Measures against dumping: Anti-dumping regulations exist to prevent the sale of steel billets in foreign markets at prices below their production cost, which can harm domestic industries. If a country determines that steel billets are being dumped into their market, they may implement anti-dumping duties or other measures to address the issue. 3. Trade agreements and barriers: The trade of steel billets can be influenced by international trade agreements, such as free trade agreements or regional trade blocs. These agreements can reduce or eliminate tariffs and other trade barriers between participating countries, facilitating smoother trade flows. Conversely, countries not party to such agreements may face higher trade barriers, making it more challenging to export or import steel billets. 4. Quality and safety standards: Steel billets must meet specific quality and safety standards set by importing countries. These standards encompass dimensions, chemical composition, mechanical properties, and other attributes. Importers and exporters must ensure that their steel billets comply with these standards to avoid rejection or additional inspection upon arrival. 5. Export controls: Certain countries impose export controls or restrictions on selected commodities, including steel billets, to secure domestic supply or protect national security interests. These controls can limit the quantity or destination of steel billet exports, necessitating exporters to acquire licenses or permits before shipping. 6. Documentation and customs requirements: The international trade of steel billets necessitates accurate documentation and adherence to customs procedures. Exporters must furnish complete and precise documentation, comprising commercial invoices, packing lists, certificates of origin, and other pertinent documents. Importers must abide by customs requirements and settle any applicable duties or fees. Remaining up-to-date with these international trade regulations is crucial for businesses involved in the trade of steel billets. Regular monitoring of changes in tariffs, anti-dumping measures, trade agreements, and quality standards is necessary to ensure compliance and make well-informed business decisions.

- Q: What are the future trends in steel billet production?

- Some of the future trends in steel billet production include advancements in automation and robotics, increased use of renewable energy sources in the production process, implementation of more efficient and sustainable production techniques, and the development of new alloys and materials to enhance the performance and strength of steel billets. Additionally, there is a growing focus on reducing carbon emissions and improving the overall sustainability of steel production, leading to the exploration of greener technologies and practices in the industry.

Send your message to us

Hot Rolled Steel Billet 3SP Standard 130mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords