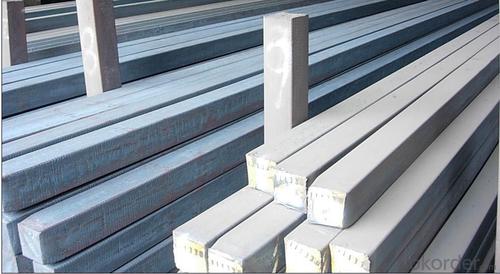

Hot Rolled Steel Billet 3SP Standard 135mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Hot Rolled Steel Billet 3SP Standard 135mm

Description of Hot Rolled Steel Billet 3SP Standard 135mm

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

Main Feature of Hot Rolled Steel Billet 3SP Standard 135mm

1.Corrosion resistance: It mainly depends on the zinc protection. When the zinc being worn,

2. Heat resistance: steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

Applications of Hot Rolled Steel Billet 3SP Standard 135mm

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; gas tank;road sign; etc.

4.Agriculture constructions :barn; etc.RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

5.Others:vending machine; game machine; auto parts spare parts etc.

Specifications of Hot Rolled Steel Billet 3SP Standard 135mm

Product | Hot Rolled Steel Billet 3SP Standard 135mm |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.5-3.0mm |

Width | 700-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled,RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 25MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Hot Rolled Steel Billet 3SP Standard 135mm

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 100 mt for each size each specification. Usually we can offer discount if can buy large QTY once. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

2. How long can we receive the product after ordering?

Our general delivery time is 30 days after confirmation, but so some special orders, we have offer special delivery time

3. How to guarantee the quality of the products?

We have established the international advanced quality management system ,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. What is the payment?

We accept T/T, L/C

- Q: How are steel billets used in the manufacturing of packaging materials?

- Steel billets are used in the manufacturing of packaging materials by being rolled into thin sheets to create metal containers or cans. These billets are first heated and then passed through a series of rolling machines to achieve the desired thickness. These sheets are further processed and shaped to form different types of packaging materials such as cans, boxes, or containers, which provide durability and strength to protect and preserve various products during transportation and storage.

- Q: How are steel billets used in the manufacturing of construction formwork?

- Steel billets are used in the manufacturing of construction formwork as they are often shaped and molded into various components, such as beams or columns, that provide essential structural support. These billets are strong and durable, ensuring the formwork can withstand the weight and pressure of poured concrete. Additionally, their malleability allows for customization, enabling the formwork to be precisely designed to meet the specific requirements of each construction project.

- Q: How are steel billets used in the production of seamless tubes?

- Seamless tubes production heavily relies on steel billets as a crucial raw material. At the initial stage of the manufacturing process, these billets are utilized for the formation of seamless tubes through hot rolling or extrusion. Initially, steel billets undergo high-temperature heating to enhance their malleability. This heating process, known as hot rolling, facilitates easy shaping and manipulation of the billets. Following this, the heated billets are passed through a series of rollers or extrusion dies, transforming them into a cylindrical shape, which serves as the fundamental structure of a seamless tube. The rolling or extrusion process subjects the steel billets to significant deformation. The pressure exerted by the rollers or dies induces the flow of metal and fills the cavities, resulting in the creation of seamless tubes. The dimensions and specifications of the final seamless tube are determined by the size and shape of the billets. In addition, steel billets contribute significantly to the mechanical properties of the seamless tubes. The quality and composition of the billets play a crucial role in determining the strength, durability, and resistance to corrosion of the tubes. Proper selection and quality control of the billets are imperative to ensure the production of seamless tubes that meet industry standards and customer requirements. To summarize, steel billets are indispensable in the production of seamless tubes. Through the processes of heating, shaping, and forming via hot rolling or extrusion, steel billets are transformed into seamless tubes with specific dimensions and mechanical properties. These high-quality seamless tubes find extensive applications in industries such as oil and gas, automotive, construction, and manufacturing.

- Q: How do steel billets contribute to the aerospace industry?

- Steel billets play a crucial role in the aerospace industry by providing the necessary raw material for manufacturing various components and structures used in aircraft. These billets, which are semi-finished metal forms, are typically produced through a process called continuous casting, where molten steel is poured into a mold to create a solid billet shape. Once the steel billets are formed, they are further processed into different aerospace components through various manufacturing techniques such as forging, machining, and heat treatment. These processes allow the steel billets to be shaped into specific forms, such as engine components, landing gear parts, structural frames, and other critical aerospace components. The use of steel billets in the aerospace industry offers several advantages. Firstly, steel is known for its high strength, durability, and excellent mechanical properties, making it a suitable material for applications where safety and reliability are of utmost importance, such as in the aerospace sector. Steel billets can withstand extreme temperatures, pressure, and stress, making them ideal for critical parts that need to perform under demanding conditions. Additionally, steel billets provide cost-effectiveness and versatility in manufacturing. Steel is widely available, making it a relatively affordable material compared to other metals used in the aerospace industry. Moreover, the ability to shape and process steel billets into various forms and sizes allows for flexibility in designing and producing aerospace components, ensuring they meet the specific requirements and standards of aircraft manufacturers. Another key contribution of steel billets to the aerospace industry is their compatibility with advanced manufacturing technologies. Steel can be easily machined, welded, and joined, enabling the integration of complex features and structures in aerospace components. This compatibility with modern manufacturing techniques allows for the production of lightweight, yet robust, parts, contributing to overall fuel efficiency and improved performance of aircraft. In conclusion, steel billets are vital to the aerospace industry as they provide the necessary raw material for manufacturing critical components and structures used in aircraft. Their high strength, durability, cost-effectiveness, and compatibility with advanced manufacturing technologies make steel billets an essential ingredient in building safe, reliable, and efficient aerospace systems.

- Q: What are the different methods of steel billet surface finishing?

- There are several methods of steel billet surface finishing, including shot blasting, grinding, and sanding. Shot blasting involves propelling small metal or abrasive particles at high speeds to remove surface impurities and create a smooth finish. Grinding uses abrasive wheels or belts to remove material and achieve the desired surface texture. Sanding involves using sandpaper or sanding pads to manually rub the surface and achieve a polished finish. Other methods may also include acid pickling or chemical treatments to remove scale or oxide layers.

- Q: What are the potential risks associated with steel billet production?

- There are several potential risks associated with steel billet production. Firstly, the production process involves the use of high temperatures and molten metal, which can pose a risk of burns and fire hazards. Operators and workers must exercise caution while handling the equipment and ensure proper safety protocols are followed to prevent accidents. Secondly, the raw materials used in steel billet production, such as iron ore and coal, can contain impurities that may release harmful gases and particulate matter during the production process. These emissions can pose health risks to workers and nearby communities if not properly controlled and mitigated. Additionally, the machinery and equipment used in steel billet production, including furnaces and rolling mills, can pose mechanical hazards if not properly maintained or operated. Accidents such as equipment malfunctions or material failures can result in injuries to workers and damage to the production facility. Furthermore, the steel industry is energy-intensive, requiring significant amounts of electricity and fossil fuels for the production process. This reliance on non-renewable energy sources contributes to greenhouse gas emissions and climate change. Efforts should be made to minimize the environmental impact through energy-efficient practices and the adoption of cleaner technologies. Lastly, the transportation of steel billets from the production facility to the next stage in the supply chain can present risks. Handling and moving heavy steel billets require proper lifting and securing techniques to prevent accidents and injuries during loading, unloading, and transportation. To mitigate these risks, it is crucial for steel billet producers to prioritize safety measures, including regular equipment inspections, proper training for workers, implementation of environmental controls, adherence to safety regulations, and continuous improvement in operational practices.

- Q: How do steel billets contribute to the overall strength of a structure?

- Steel billets contribute to the overall strength of a structure by serving as the raw material for various structural components. They are made from molten steel that is solidified into a rectangular shape, resulting in a dense and homogeneous material. These billets are then further processed and formed into beams, columns, and other load-bearing elements. Their high strength and durability allow them to withstand heavy loads and forces, enhancing the overall structural integrity of the building or infrastructure.

- Q: What are the main disadvantages of using steel billets?

- Using steel billets in various industries comes with several disadvantages. To begin with, one major drawback of steel billets is their high cost. The manufacturing process of steel billets is complex, involving the melting and casting of steel, which can be quite expensive. Consequently, this cost is then passed on to the end product, making it less affordable for consumers. Moreover, steel billets tend to be heavy and bulky, making transportation and handling challenging. The weight and size of steel billets contribute to logistical difficulties in the supply chain, leading to increased costs and potential delays. Another disadvantage is the limited availability of steel billets. Steel production requires a substantial amount of resources and energy, and the availability of raw materials can be restricted, resulting in potential disruptions in the supply chain. This scarcity can have a negative impact on industries heavily reliant on steel billets for their operations. Furthermore, steel billets have limited shape flexibility. They are typically produced in standardized sizes and shapes, making customization for specific design requirements difficult. This lack of flexibility can be a significant drawback for industries that necessitate intricate and unique shapes for their products. Moreover, steel billets are susceptible to corrosion if not properly treated. Exposure to moisture and certain environments can lead to rust and degradation, reducing the lifespan and durability of products made from steel billets. Regular maintenance and anti-corrosion treatments are essential to mitigate this disadvantage. Lastly, the production of steel billets has a significant environmental impact. The manufacturing process emits greenhouse gases and consumes substantial amounts of energy and water. These environmental concerns have resulted in increased scrutiny and regulations on steel production, thereby adding extra costs and complexities to the use of steel billets. In conclusion, while steel billets offer advantages in terms of strength and durability, they also come with several drawbacks. These include high costs, transportation challenges, limited availability, lack of shape flexibility, susceptibility to corrosion, and environmental impact. Industries must carefully consider these disadvantages when evaluating the use of steel billets in their operations.

- Q: How are steel billets used in the production of construction machinery attachments?

- Steel billets are commonly used in the production of construction machinery attachments as they serve as the raw material for manufacturing various components. These billets are shaped and processed through different methods like forging, cutting, and welding to create essential parts such as buckets, blades, booms, and arms. The high strength and durability of steel make it ideal for withstanding the demanding conditions and heavy loads encountered in construction sites.

- Q: What are the weight ranges of steel billets?

- The weight of steel billets can vary based on the industry's specific requirements and standards. Generally, steel billets can weigh anywhere from a few kilograms to several metric tons. The weight of a steel billet is determined by factors like its dimensions, intended application, and production process. Smaller steel billets, used in construction or manufacturing, typically weigh between 1 to 10 kilograms. Conversely, larger steel billets, commonly utilized in heavy machinery or infrastructure projects, can weigh anywhere from 10 to 100 metric tons or potentially more. It is important to note that these weight ranges are approximate estimates and may differ depending on the particular industry requirements and production capabilities.

Send your message to us

Hot Rolled Steel Billet 3SP Standard 135mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords