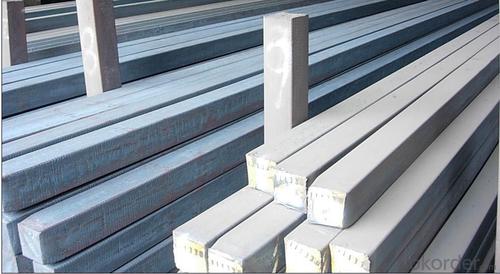

Hot Rolled Steel Billet 3SP Standard 155mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Hot Rolled Steel Billet 3SP Standard 155mm

Description of Hot Rolled Steel Billet 3SP Standard 155mm

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

Main Feature of Hot Rolled Steel Billet 3SP Standard 155mm

1.Corrosion resistance: It mainly depends on the zinc protection. When the zinc being worn,

2. Heat resistance: steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

Applications of Hot Rolled Steel Billet 3SP Standard 155mm

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; gas tank;road sign; etc.

4.Agriculture constructions :barn; etc.RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

5.Others:vending machine; game machine; auto parts spare parts etc.

Specifications of Hot Rolled Steel Billet 3SP Standard 155mm

Product | Hot Rolled Steel Billet 3SP Standard 155mm |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.5-3.0mm |

Width | 700-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled,RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 25MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Hot Rolled Steel Billet 3SP Standard 155mm

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 100 mt for each size each specification. Usually we can offer discount if can buy large QTY once. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

2. How long can we receive the product after ordering?

Our general delivery time is 30 days after confirmation, but so some special orders, we have offer special delivery time

3. How to guarantee the quality of the products?

We have established the international advanced quality management system ,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. What is the payment?

We accept T/T, L/C

- Q: What are the major steel billet producing countries?

- The major steel billet producing countries include China, India, Russia, Japan, and the United States.

- Q: What are the different types of welding processes used for joining steel billets?

- When it comes to joining steel billets, there are various welding processes available, each with its own unique characteristics and advantages depending on the project's specific requirements. Here, we present some of the commonly used welding processes for joining steel billets: 1. Shielded Metal Arc Welding (SMAW), also known as stick welding, utilizes a consumable electrode coated in flux that creates an arc between the electrode and the base material. This versatile process can be used for both thick and thin steel billets, making it widely employed in various industries. 2. Gas Metal Arc Welding (GMAW), commonly referred to as MIG welding, involves a continuous wire electrode and a shielding gas that protects the weld from atmospheric contamination. This process offers high productivity and is suitable for welding steel billets of different thicknesses. 3. Flux-Cored Arc Welding (FCAW), similar to GMAW, employs a continuously fed tubular electrode filled with flux. It is particularly suitable for welding thicker steel billets and finds applications in heavy fabrication. 4. Gas Tungsten Arc Welding (GTAW), also known as TIG welding, utilizes a non-consumable tungsten electrode and a separate filler metal. This process produces high-quality welds and is commonly used in applications that require precision and aesthetic appeal. 5. Submerged Arc Welding (SAW) involves a continuously fed electrode and a granular flux that covers the weld area. It is particularly suitable for welding thick steel billets and is often used in the construction of pressure vessels and heavy machinery. 6. Laser Beam Welding (LBW) employs a laser beam to generate heat and join the steel billets. This process offers high precision and speed, making it suitable for a wide range of applications, including automotive and aerospace industries. 7. Electron Beam Welding (EBW) uses a high-velocity electron beam to melt and join the steel billets. This process provides deep penetration and precise control, making it ideal for critical applications that require high-quality welds. When selecting the appropriate welding process, it is crucial to consider the specific requirements, thickness, and material properties of the steel billets. Consulting with a welding expert can help determine the most suitable method for a given project.

- Q: How are steel billets used in the manufacturing of packaging equipment?

- Packaging equipment relies heavily on steel billets as a vital element in its manufacturing process. These billets serve as the primary material for producing diverse parts and components crucial to the functioning of packaging machinery. To begin with, steel billets are typically employed in the fabrication of packaging equipment frames and structures. The robust nature and enduring quality of steel make it an ideal selection for constructing a sturdy framework that provides support to the entire machine. This guarantees that the packaging equipment can endure the demands of continuous operation and heavy loads. Furthermore, steel billets are also instrumental in the production of significant components such as gears, shafts, and rollers. These components play a pivotal role in ensuring the smooth operation and rotation required for efficient product packaging. Steel's exceptional mechanical properties, including high tensile strength and resistance to wear and tear, render it suitable for these critical parts. Additionally, steel billets are frequently utilized in the manufacturing of cutting and forming tools employed in packaging equipment. These tools are responsible for shaping and cutting various materials like cardboard or plastic to create packaging containers or wrap products. The hardness of steel and its ability to maintain sharp edges make it an ideal material for crafting these tools, thus ensuring precise and efficient packaging operations. In conclusion, the significance of steel billets in the manufacturing of packaging equipment cannot be overstated, as they are instrumental in creating the frames, components, and tools necessary for the efficient and reliable operation of packaging machinery. The strength, durability, and versatility of steel billets make them the preferred choice in the packaging industry.

- Q: What is the lifespan of a steel billet?

- The lifespan of a steel billet can vary depending on several factors such as the quality of the steel, the conditions in which it is stored and used, and the specific application it is being used for. Generally, steel billets are designed to have a long lifespan and can be used for many years without significant degradation. Steel billets are typically made from high-quality steel that is specifically engineered to have excellent strength, durability, and resistance to corrosion. This ensures that the billet can withstand the rigors of various industrial processes and applications. In terms of storage and usage conditions, steel billets need to be stored in a dry and controlled environment to prevent moisture and other contaminants from causing rust or degradation. They should also be handled and transported carefully to prevent any physical damage that could compromise their integrity. The lifespan of a steel billet also depends on the specific application it is being used for. Some billets are used in high-stress applications such as construction, automotive manufacturing, or heavy machinery, where they may undergo significant wear and tear. In these cases, the lifespan of the billet can be shorter compared to less demanding applications. Overall, with proper care, maintenance, and adherence to recommended usage guidelines, a steel billet can have a long lifespan ranging from several years to decades. Regular inspections, maintenance, and replacement of worn or damaged billets are essential to ensure optimal performance and safety in various industries.

- Q: How are steel billets used in the production of fasteners?

- Steel billets are used in the production of fasteners as they serve as the raw material for manufacturing various types of fasteners such as bolts, screws, and nuts. These billets are heated and then forged or rolled to shape them into the desired fastener form. The resulting fasteners possess high strength and durability, making them suitable for a wide range of applications in industries like construction, automotive, and manufacturing.

- Q: How do steel billets contribute to the manufacturing of construction machinery?

- Steel billets play a crucial role in the manufacturing of construction machinery. These cylindrical or square bars of steel are the primary raw material used in the production of various components and parts for construction machinery. Firstly, steel billets are used to create the structural frame of construction machinery. The high strength and durability of steel make it an ideal material for ensuring the structural integrity of heavy machinery. Steel billets are shaped and welded together to form the sturdy frame, providing the necessary support and stability to the equipment. Additionally, steel billets are used to manufacture critical components such as gears, shafts, and axles. These components require high tensile strength and resistance to wear and tear, which can be achieved using steel billets. By machining, forging, or casting steel billets into the desired shape, these components can withstand the heavy loads and harsh operating conditions in the construction industry. Moreover, steel billets are used to produce buckets, blades, and cutting edges for construction machinery. These components are subjected to extreme forces and abrasion during excavation, grading, and other construction activities. Steel billets, with their excellent hardness and toughness, ensure that these components can withstand the demanding conditions and perform effectively. Furthermore, steel billets are essential in the production of hydraulic cylinders and pistons. These components are responsible for generating the force required for lifting, pushing, and pulling heavy loads in construction machinery. Steel billets are machined and shaped to create the cylinder bodies and pistons, ensuring the necessary strength and precision for efficient hydraulic operations. In summary, steel billets are indispensable in the manufacturing of construction machinery. They provide the strength, durability, and wear resistance required for the various components and parts of construction equipment. Steel billets contribute to the overall performance and reliability of construction machinery, ensuring that they can withstand the demanding conditions and heavy workloads encountered in the construction industry.

- Q: What are the different grades of steel billets?

- Different grades of steel billets exist, each possessing unique properties and applications. Some commonly used grades include the following: 1. Mild Steel Billets: Utilized in general construction and engineering applications, these are low carbon steel billets. They possess relatively low tensile strength but are easily weldable and formable. 2. Carbon Steel Billets: Compared to mild steel billets, these billets have higher carbon content, resulting in increased strength and hardness. They find common use in manufacturing automotive parts, machinery, and tools. 3. Alloy Steel Billets: These billets are steel billets that have been alloyed with other elements like chromium, nickel, or molybdenum, enhancing specific properties. They offer improved strength, toughness, and corrosion resistance, making them suitable for applications in the aerospace, defense, and oil and gas industries. 4. Stainless Steel Billets: Containing high levels of chromium and nickel, these billets exhibit excellent corrosion resistance and durability. They are widely employed in the production of kitchen appliances, cutlery, and medical equipment. 5. High-Speed Steel Billets: These billets are alloyed with tungsten, molybdenum, or vanadium, resulting in steel with exceptional hardness and heat resistance. Primarily, they are used in the production of cutting tools like drill bits and saw blades. It is essential to note that the specific grades of steel billets may vary depending on manufacturing standards and the region. These grades are classified based on their chemical composition, mechanical properties, and intended applications, ensuring the appropriate selection of steel billets for desired end uses.

- Q: What are the properties of high-quality steel billets?

- High-quality steel billets possess several key properties that make them desirable for various applications. First and foremost, these billets have a high level of purity, meaning they contain minimal impurities such as sulfur, phosphorus, and other non-metallic elements. This purity contributes to the overall strength and performance of the steel. Another important property of high-quality steel billets is their uniform internal structure. This means that the grains within the billet are evenly distributed, resulting in consistent mechanical properties throughout the material. This uniformity enhances the strength, toughness, and durability of the steel. High-quality steel billets also exhibit excellent dimensional accuracy. They have precise and consistent dimensions, which are crucial for subsequent processing and manufacturing operations. This dimensional accuracy ensures that the billets can be easily formed, rolled, forged, or machined into their intended final shapes. Furthermore, high-quality steel billets possess superior surface finish. They are free from defects such as cracks, voids, or inclusions on their surfaces. This smooth and defect-free surface allows for better heat transfer, improved corrosion resistance, and enhanced aesthetic appearance of the final steel products. Lastly, high-quality steel billets exhibit excellent metallurgical properties. They have a well-controlled chemical composition, which determines their specific mechanical and physical characteristics. These properties can be tailored to meet the requirements of different applications, such as high strength, high ductility, or resistance to extreme temperatures. In summary, high-quality steel billets possess properties such as purity, uniform internal structure, dimensional accuracy, excellent surface finish, and desirable metallurgical properties. These properties make them ideal for a wide range of applications, including construction, automotive, aerospace, and manufacturing industries.

- Q: What is the role of steel billets in the construction of residential buildings?

- Steel billets play a crucial role in the construction of residential buildings. These long, rectangular-shaped steel bars serve as the primary raw material for the production of various structural components used in the construction process. One of the key applications of steel billets is in the fabrication of reinforced concrete structures. Reinforced concrete is widely used in building foundations, columns, beams, and slabs due to its high strength and durability. Steel billets are used to manufacture rebar, which is then embedded within the concrete to provide tensile strength and enhance the structural integrity of the building. The use of steel reinforcement ensures that the building can withstand external forces, such as wind, seismic activity, and the weight of the structure itself. Additionally, steel billets are utilized in the production of steel beams and columns. These components are essential for supporting the weight of the building and transferring loads from the upper floors to the foundation. Steel beams offer superior strength and rigidity, allowing for the construction of open, spacious interiors without the need for excessive support walls. This not only provides flexibility in design but also maximizes the usable space in residential buildings. Steel billets are also utilized in the construction of stairs, handrails, and balconies. These elements require high-strength materials to ensure the safety and longevity of the structure. Steel billets provide the necessary strength and stability to these components, allowing for safe and secure access to different areas of the building. In summary, steel billets are crucial in the construction of residential buildings as they serve as the raw material for various structural components. From reinforced concrete structures to steel beams, columns, and other architectural elements, steel billets play a vital role in ensuring the strength, durability, and overall safety of residential buildings.

- Q: What is the role of steel billets in the production of valves and fittings?

- Steel billets play a crucial role in the production of valves and fittings as they serve as the primary raw material for manufacturing these products. The billets are heated and then shaped and formed through various processes like forging, machining, and welding to create the desired valve or fitting. The high strength and durability of steel billets ensure the reliability and longevity of valves and fittings, making them essential components in industries such as oil and gas, water treatment, and manufacturing.

Send your message to us

Hot Rolled Steel Billet 3SP Standard 155mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords