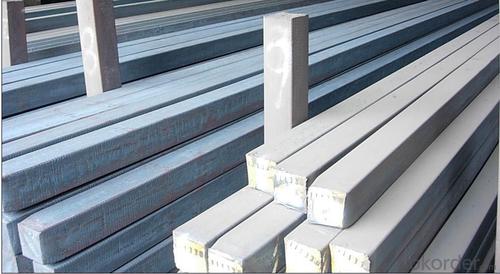

Hot Rolled Steel Billet 3SP Standard 145mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Hot Rolled Steel Billet 3SP Standard 145mm

Description of Hot Rolled Steel Billet 3SP Standard 145mm

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

Main Feature of Hot Rolled Steel Billet 3SP Standard 145mm

1.Corrosion resistance: It mainly depends on the zinc protection. When the zinc being worn,

2. Heat resistance: steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

Applications of Hot Rolled Steel Billet 3SP Standard 145mm

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; gas tank;road sign; etc.

4.Agriculture constructions :barn; etc.RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

5.Others:vending machine; game machine; auto parts spare parts etc.

Specifications of Hot Rolled Steel Billet 3SP Standard 145mm

Product | Hot Rolled Steel Billet 3SP Standard 145mm |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.5-3.0mm |

Width | 700-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled,RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 25MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Hot Rolled Steel Billet 3SP Standard 145mm

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 100 mt for each size each specification. Usually we can offer discount if can buy large QTY once. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

2. How long can we receive the product after ordering?

Our general delivery time is 30 days after confirmation, but so some special orders, we have offer special delivery time

3. How to guarantee the quality of the products?

We have established the international advanced quality management system ,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. What is the payment?

We accept T/T, L/C

- Q: What are the main factors affecting the corrosion resistance of stainless steel billets?

- The main factors affecting the corrosion resistance of stainless steel billets include the composition of the stainless steel alloy, specifically the percentage of chromium present, as well as the presence of other alloying elements such as nickel and molybdenum. The microstructure of the stainless steel, including the presence of ferrite and austenite phases, also plays a role in corrosion resistance. Additionally, factors such as the pH and temperature of the environment, the presence of corrosive substances, and the surface finish of the billets can affect their corrosion resistance.

- Q: What are the different types of steel billet defects?

- There are various types of steel billet defects, including surface defects like cracks, laps, and scars, as well as internal defects such as segregation, porosity, and inclusions.

- Q: How do steel billets contribute to the overall corrosion protection of a structure?

- Steel billets, classified as semi-finished steel products, play a crucial role in safeguarding structures against corrosion. They contribute to corrosion protection through multiple means: 1. Superior steel composition: Steel billets are crafted from top-notch steel that comprises different alloying elements, like chromium, nickel, and molybdenum. These elements amplify the steel's resistance to rust and corrosion, making it less vulnerable. 2. Protective layering: Steel billets are often coated with protective layers, such as zinc or epoxy coatings. These coatings function as a barrier between the steel surface and the external environment, obstructing moisture, oxygen, and other corrosive substances from reaching the steel and causing corrosion. 3. Enduring strength: Steel billets are renowned for their remarkable strength and durability. When utilized in construction, they provide a robust foundation and structural support. This strength and durability minimize the likelihood of structural damage and corrosion, guaranteeing the stability and longevity of the structure. 4. Welding capability: Steel billets possess exceptional weldability, facilitating easy and efficient joining of steel components during construction. Proper welding techniques and materials can further augment the structure's corrosion resistance by preserving the integrity and continuity of the protective coatings. 5. Maintenance and repair: In the event of damage or corrosion on the structure, steel billets can be readily replaced or repaired. This ensures that the affected area can be rectified without compromising the overall integrity and corrosion protection of the structure. Regular maintenance and repair of steel billets contribute to the long-term corrosion protection of the entire structure. In conclusion, steel billets contribute significantly to the overall corrosion protection of structures through their high-quality composition, protective coatings, durability, weldability, and ease of maintenance and repair. By incorporating steel billets into construction projects, engineers and architects can ensure the longevity, safety, and corrosion resistance of structures in diverse environments.

- Q: How are steel billets stored?

- Steel billets are typically stored in open yards or covered warehouses, stacked neatly on top of each other in rows or piles. They are often placed on wooden or steel skids to protect them from moisture and to facilitate easy movement using forklifts or cranes. Additionally, billets are commonly stored in a way that allows proper ventilation and accessibility for inspection and transportation purposes.

- Q: How are steel billets priced in the market?

- Steel billets are typically priced in the market based on various factors such as supply and demand dynamics, production costs, and market conditions. The pricing is influenced by factors such as raw material costs, energy prices, transportation costs, and any applicable taxes or duties. Additionally, market participants consider factors like global economic trends, industry forecasts, and geopolitical events that may impact the overall steel market. Ultimately, steel billet pricing is determined through negotiations between buyers and sellers based on these various factors.

- Q: How are steel billets used in the production of transmission towers?

- Steel billets are used in the production of transmission towers as the raw material for manufacturing tower sections. These billets are cut, shaped, and welded to create the structural components of the towers, ensuring strength, stability, and durability in supporting electrical transmission lines.

- Q: What are the advantages of using steel billets in the manufacturing process?

- There are several advantages of using steel billets in the manufacturing process. Firstly, steel billets have a consistent composition and uniformity, which ensures better quality control during production. Secondly, steel billets can be easily molded into various shapes and sizes, allowing for flexibility in design and manufacturing. Additionally, steel billets possess high strength and durability, making them suitable for applications that require robust materials. Moreover, steel billets can be recycled and reused, making them an environmentally friendly choice. Overall, the use of steel billets enhances the efficiency, reliability, and sustainability of the manufacturing process.

- Q: How do steel billets contribute to the manufacturing of household appliances?

- The manufacturing of household appliances heavily relies on steel billets, as they serve as the fundamental material for creating various components and structures used in these appliances. To begin with, steel billets are utilized in the production of frames and structures for appliances like refrigerators, washing machines, and dishwashers. The exceptional strength and durability of steel make it an ideal choice for these purposes, ensuring that the appliances can endure constant use and heavy loads. Moreover, steel billets are employed in the manufacturing of both inner and outer panels for household appliances. These panels require a material that possesses strength, resistance to corrosion, and aesthetic appeal. Steel perfectly meets these criteria, providing a sleek and long-lasting surface that can be easily cleaned and maintained. In addition, steel billets are essential for creating various components found within household appliances, including heating elements, motors, and electrical parts. Steel's remarkable thermal conductivity and electrical properties make it a suitable material for these crucial components, guaranteeing efficient operation and reliable performance. Additionally, steel billets contribute significantly to the overall safety of household appliances. Steel is highly resistant to fire, reducing the risk of accidents caused by overheating or electrical malfunctions. Furthermore, its strength and stability play a vital role in preventing structural failures that could lead to accidents or injuries. In summary, the strength, durability, corrosion resistance, and thermal/electrical properties of steel billets make them indispensable in the manufacturing of household appliances. By providing the necessary raw material, steel billets enable the production of robust structures, appealing panels, critical components, and safe appliances that meet the expectations and demands of consumers.

- Q: What are the different surface treatments available for steel billets?

- There are several different surface treatments available for steel billets, each serving a specific purpose and offering unique benefits. Some of the commonly used surface treatments for steel billets include: 1. Hot-dip galvanizing: This process involves immersing the steel billets in a bath of molten zinc, creating a protective coating that helps prevent corrosion. Hot-dip galvanizing provides excellent corrosion resistance and durability, making it suitable for outdoor applications. 2. Electroplating: Electroplating involves depositing a layer of metal onto the surface of the steel billets using an electrical current. This treatment can enhance the appearance of the steel while providing corrosion resistance and improving wear resistance. 3. Powder coating: Powder coating is a dry finishing process where a fine powder is electrostatically applied to the steel billets and then cured under heat. This treatment creates a durable and attractive finish that is resistant to chipping, scratching, and fading. 4. Passivation: Passivation is a chemical treatment that removes contaminants and creates a protective oxide layer on the surface of the steel billets. This process enhances the corrosion resistance of the steel and improves its appearance. 5. Phosphating: Phosphating involves applying a phosphate coating to the steel billets, which enhances corrosion resistance and improves paint adhesion. Phosphating is commonly used as a pre-treatment before painting or powder coating. 6. Shot blasting: Shot blasting is a mechanical surface treatment that involves blasting steel billets with small abrasive particles at high velocity. This process removes surface contaminants, scales, and rust, resulting in a clean and roughened surface suitable for further treatments or coatings. 7. Acid pickling: Acid pickling is a chemical treatment that removes oxide scales, rust, and other impurities from the surface of the steel billets. This treatment provides a clean and smooth surface, preparing the steel for subsequent processing or coating. These are just a few examples of the surface treatments available for steel billets. The choice of treatment depends on the specific requirements of the application, including corrosion resistance, appearance, and functional properties. It is essential to consider factors such as cost, environmental impact, and performance expectations when selecting the appropriate surface treatment for steel billets.

- Q: What are the different types of rolling processes used for shaping steel billets?

- Steel billets can be shaped into desired forms using different rolling processes. These processes have been designed to transform raw materials into specific shapes and sizes. One widely used method is hot rolling, which involves heating the steel billet to a high temperature and passing it through a series of rollers. The pressure applied by the rollers causes the billet to elongate and change its shape. Hot rolling is commonly employed to produce large steel products like bars, rods, and plates. Another method is cold rolling, which does not require heating the steel billet. Instead, it is carried out at room temperature or slightly below. Cold rolling is known for its ability to produce accurately dimensioned finished products with a smooth surface. It is often used in the manufacturing of thin sheets, strips, and foils. Ring rolling is a third type of rolling process used for shaping steel billets. It involves rotating the billet between two rollers while exerting pressure. This method is particularly useful for creating seamless rings with hollow centers, which are commonly utilized in applications such as bearings and gears. Furthermore, skew rolling is a process used to shape steel billets into round balls or cylindrical forms. It entails rotating the billet at an angle to the direction of the rollers while applying pressure. Skew rolling finds extensive use in the production of grinding media for the mining and cement industries. In conclusion, the various rolling processes, including hot rolling, cold rolling, ring rolling, and skew rolling, offer distinct advantages and are suitable for specific applications. Each process plays a crucial role in shaping steel billets to meet the requirements of different industries.

Send your message to us

Hot Rolled Steel Billet 3SP Standard 145mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords