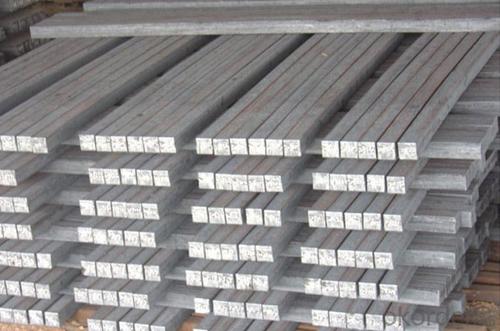

Steel Square Billet Bar For Rebar Production

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Range of thickness: 150-240 - mm +/- 5 mm width range: 880-1530 - mm +/- 20 mm

Length: 3700-10000 - mm +/- 500 - mm

Cross-sectional size: 64 * 64; 82 * 82; 98 * 98; 124 * 124; 120 * 150; 152 * 164; 152 * 170 mm

Length: 9000 mm

Section of tolerance: billet: 1.0 +/- 2.0-1.0 +/- 1.0 mm slab: width: +/- 2.0 mm thickness: +/- 3.0 mm

The length tolerance: +/- 200 mm

Section diagonal tolerance: 3.5-8.0 MM

Billet section size protrusions requirements: < 1242 mm, do not allow; > = 1242 mm, < = 2 mm 1242 mm, < = 3 mm

Beheading (shear) extension deformation: < 1242 mm billet: no control; The slab: < = 15 mm

Surface tilt: no more than billet section 0.1

Bending: every 1 m length is not more than 10 mm.

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, Formula for theoretical weight of Square bar: (length of a side)2 * 0.00785

3, The numbers with *mean that they are not regular or we don’t offer them.

-Regular length of Square Bar:

Steel | Length of a side (mm) | Length of steel (m) |

Normal steel | < 25 | 4~10 |

> 25 | 3~9 | |

Steel of high quality | All measure | 2~6 |

Tool steel >75 | 1~6 |

Usage/Applications

-The Square Bar is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Packaging & Delivery

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks: We make tag marks and color marks. The tag marks with white background and red company logo will be tied up to each bundle of the products. The information is usually including basic information of products and company and other information requested by customers. As for color marks, we will paint both ends of bundles to make sure that it will be more convenient for customers to distinguish them from other products.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation

-The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products are usually transported to the nearest port from the production place.

- Q: How are steel billets used in the manufacturing of automotive engine components?

- Steel billets are an essential raw material used in the manufacturing of automotive engine components. These billets are semi-finished steel products that are cast into specific shapes and sizes. They serve as the building blocks for various engine parts, such as crankshafts, connecting rods, camshafts, and cylinder blocks. Steel billets undergo a series of processes to transform them into engine components. The first step involves heating the billets to a high temperature, making them malleable and ready for forging or machining. Forging is a common method used to shape the billets into desired forms. It involves applying pressure and force to the heated billet to mold it into the required shape, such as the curved shape of a crankshaft. Once the billets have been forged into the desired shape, they undergo further machining processes to refine their dimensions and achieve the desired level of accuracy. This includes drilling, milling, turning, and grinding, which are performed using specialized machinery and tools. Machining ensures that the engine components meet the strict tolerances required for optimal performance and reliability. Steel billets are chosen for their exceptional strength, durability, and heat resistance properties. These characteristics are vital for engine components, as they are subjected to high pressures, temperatures, and loads during operation. Steel's high tensile strength and ability to withstand extreme conditions make it an ideal material for these critical parts. In summary, steel billets play a crucial role in the manufacturing of automotive engine components. Through forging and machining processes, they are transformed into highly precise and durable parts that contribute to the smooth and efficient operation of an engine. The use of steel billets ensures the overall quality and performance of automotive engines, making them an integral part of the manufacturing process.

- Q: What are the main factors that affect the availability of steel billets?

- There are several main factors that affect the availability of steel billets. Firstly, the availability of raw materials plays a crucial role. Steel billets are produced by melting iron ore, along with other materials such as coal and limestone, in a blast furnace. The availability and cost of these raw materials can greatly impact the production of steel billets. Any disruptions in the supply chain, such as a shortage of iron ore or a spike in prices, can lead to a decrease in the availability of steel billets. Secondly, the demand for steel billets also influences their availability. The construction and manufacturing industries are the primary consumers of steel billets, using them to produce various steel products such as bars, rods, and beams. If there is a surge in demand for steel products, it can strain the availability of steel billets, especially if the production capacity is not able to keep up with the increased demand. Furthermore, market dynamics and economic conditions can impact the availability of steel billets. Factors such as fluctuations in steel prices, changes in government policies, and trade barriers can affect the overall supply and demand balance. For example, the implementation of tariffs or restrictions on steel imports can reduce the availability of steel billets in a particular region, as domestic production may not be able to meet the demand. Additionally, technological advancements and production capabilities also play a role in determining the availability of steel billets. Improvements in manufacturing processes, such as the use of electric arc furnaces or continuous casting, can increase production efficiency and output. On the other hand, any technical issues or maintenance problems in steel plants can lead to disruptions in production and subsequently reduce the availability of steel billets. In conclusion, the availability of steel billets is influenced by factors such as the availability and cost of raw materials, the demand for steel products, market dynamics, economic conditions, and technological advancements. These factors can individually or collectively impact the availability of steel billets, and it is important for stakeholders in the steel industry to monitor and address these factors to ensure a stable supply of steel billets.

- Q: What are the common defects found in steel billets?

- Steel billets can exhibit various defects, both from the manufacturing process and external factors. One such defect is surface cracks, which can arise from inadequate cooling, handling, or excessive stress during rolling or forming. These cracks can weaken the billet and compromise its strength and integrity. Internal voids or inclusions are another common defect, caused by impurities or foreign particles in the steel. These voids create weak points in the billet, potentially leading to structural failures or diminished mechanical properties. Misalignment or misshaping is a defect that occurs during cooling or forming, resulting in uneven thickness or dimensions. This flaw adversely impacts the billet's performance and suitability for its intended application. Furthermore, excessive segregation of alloying elements can lead to uneven property distribution within the billet. This inconsistency hampers the mechanical properties and overall quality. Lastly, surface defects like scale, pitting, or imperfections can manifest due to improper handling, storage, or exposure to harsh environments. Though these defects may not affect the billet's structural integrity, they do impact the surface finish and aesthetics of the final product. To ensure the production of high-quality and reliable steel products, it is crucial to identify and address these common defects in steel billets. Regular inspections, quality control measures, and appropriate handling and storage techniques play vital roles in minimizing and preventing these defects.

- Q: How are steel billets used in the manufacturing of furniture?

- Furniture manufacturing commonly utilizes steel billets as the primary material for various components. These billets undergo heating and molding processes to take on different shapes, ultimately forming the structural framework of chairs, tables, and bed frames. The use of steel in furniture production is preferred due to its malleability and strength, which contribute to the durability and stability of the final product. Furthermore, steel billets can be easily welded and joined together, allowing for the creation of intricate designs and structures. In summary, steel billets play a crucial role in the manufacturing of high-quality and long-lasting furniture pieces, providing the necessary strength and versatility.

- Q: What are the different types of surface defect detection methods for steel billets?

- There are several types of surface defect detection methods for steel billets, including visual inspection, magnetic particle inspection, ultrasonic testing, eddy current testing, and dye penetrant testing. Each method has its own advantages and limitations, and is used depending on the specific requirements and characteristics of the billets being inspected.

- Q: How are steel billets used in the production of structural steel sections?

- Steel billets are a crucial component in the production of structural steel sections. These billets serve as the primary raw material for the manufacturing process. To begin with, steel billets are melted in a furnace to create molten steel. This molten steel is then cast into billets of specific sizes and shapes, which can vary depending on the desired structural steel section to be produced. The billets are typically rectangular or square in shape. Once the steel billets have solidified, they are reheated in another furnace to a specific temperature for hot rolling. Hot rolling is a process where the billets are passed through a series of rolling mills to reduce their cross-sectional area and shape them into the desired structural steel sections. This process involves applying high pressure and temperature to the billets, which causes them to deform and elongate. The hot rolled steel sections are cooled and then undergo further processing, such as straightening, cutting, and sometimes additional heat treatment to enhance their mechanical properties. These steps ensure that the structural steel sections meet the required specifications for strength, durability, and dimensional accuracy. The structural steel sections produced from steel billets are widely used in various construction projects. They are commonly used in the construction of buildings, bridges, infrastructure, and other structures where strength and load-bearing capacity are essential. These sections can be found in beams, columns, channels, angles, and other shapes that provide the necessary support and structural integrity. Overall, steel billets play a vital role in the production of structural steel sections, serving as the starting material that undergoes a series of manufacturing processes to create the final products used in construction and other industries.

- Q: Can steel billets be used in the production of utensils and cutlery?

- Utensils and cutlery can indeed be produced using steel billets. These semi-finished products have the potential to be transformed into a variety of shapes and forms, including utensils and cutlery. The remarkable properties of steel, such as its strength, durability, and resistance to corrosion, make it an ideal choice for manufacturing these items. In the production process, steel billets are often melted and cast into specific shapes. They are then further processed through techniques like forging, stamping, or machining to create the desired utensils and cutlery items. The range of final products is extensive, encompassing not only spoons, forks, and knives but also more intricate items like serving spoons, ladles, and cheese slicers. Steel utensils and cutlery are highly regarded and widely used due to their long-lasting nature and hygienic qualities.

- Q: How are steel billets used in the construction industry?

- Steel billets are used in the construction industry as raw materials for manufacturing various steel products such as beams, columns, and reinforcing bars. They are heated and shaped into different forms to be used in the construction of buildings, bridges, and other infrastructure projects.

- Q: How do steel billets contribute to the overall strength of a structure?

- Steel billets play a crucial role in contributing to the overall strength of a structure. These billets, which are essentially semi-finished forms of steel, are used as raw material in the production of various structural components. One of the primary reasons steel billets enhance the strength of a structure is due to the inherent properties of steel itself. Steel is known for its exceptional strength and durability, making it an ideal material for construction purposes. When steel billets are used in the manufacturing process, they provide a solid foundation for creating stronger structural elements. Steel billets are typically hot-rolled or forged to shape different structural components, such as beams, columns, and plates. During the manufacturing process, the steel is subjected to high temperatures and pressure, resulting in a refined grain structure. This refined grain structure enhances the strength and toughness of the steel, making it more resistant to deformation and structural failure. Moreover, steel billets can be further processed to achieve specific mechanical properties that are required for different structural applications. For example, the billets can undergo heat treatment processes such as quenching and tempering, which improve their hardness and toughness. This allows the steel to withstand higher loads and stresses, thereby contributing to the overall strength and stability of the structure. In addition to their inherent strength, steel billets also offer advantages in terms of versatility and design flexibility. They can be easily shaped into various sizes and dimensions, allowing engineers to create complex structural configurations. This versatility enables the optimization of the structural design, ensuring that the load-bearing capacity and overall strength of the structure are maximized. Furthermore, steel billets have excellent weldability, allowing them to be seamlessly joined with other steel components. This ensures the integrity and continuity of the structure, preventing weak points or potential failure zones. By creating a unified and interconnected system, the steel billets contribute to the overall strength and stability of the structure. In conclusion, steel billets make a significant contribution to the overall strength of a structure through their inherent strength, refined grain structure, and ability to undergo various heat treatment processes. They provide a solid foundation for manufacturing structural components, allowing them to withstand high loads and stresses. The versatility and design flexibility of steel billets further optimize the structural design, while their excellent weldability ensures the integrity of the structure. Consequently, steel billets are essential in creating robust and durable structures that can withstand the test of time.

- Q: What is the role of steel billets in the manufacturing of automotive body panels?

- The manufacturing of automotive body panels heavily relies on steel billets, which are essential semi-finished metal products. These billets serve as the initial material for creating various components that compose a car's body. The primary rationale behind using steel billets in this process lies in their exceptional strength and durability. Automotive body panels need to endure different external forces and impacts, such as collisions, extreme weather conditions, and everyday wear and tear. Steel, being a robust and inflexible material, provides the necessary structural integrity to ensure the vehicle's safety and longevity. Furthermore, steel billets offer versatility in terms of design and customization. They can be effortlessly molded and shaped into different forms and sizes, enabling manufacturers to produce body panels with precise specifications. This adaptability allows for the creation of diverse car models with unique designs that meet the varied demands of consumers. Additionally, steel billets are favored for their cost-effectiveness. Steel is a widely available and relatively inexpensive material, making it a practical option for large-scale production. Moreover, its recyclability further reduces production costs and lessens environmental impact. In conclusion, the role of steel billets in the manufacturing of automotive body panels is of utmost importance. They provide the necessary strength, durability, versatility, and cost-effectiveness required for producing high-quality and dependable car bodies.

Send your message to us

Steel Square Billet Bar For Rebar Production

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords