When Was Rebar Invented

When Was Rebar Invented Related Searches

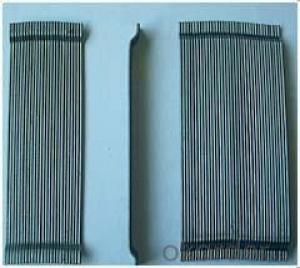

Rebar Identification Ss Rebar Rebar Coil Rebar Lengths Standard Rebar 10Mm Gfrp Rebar T10 Rebar Rebar Tensile Strength Frp Rebar Billet Rebar Y16 Rebar 30M Rebar 18J Rebar Rebar Stirrups Blue Steel Rebar Billet Steel Rebar Re Bars Grade 80 RebarWhen Was Rebar Invented Supplier & Manufacturer from China

Rebar, short for reinforcing bar, is a critical component in the construction industry, invented in the early 20th century. This steel bar is used to reinforce concrete structures, providing strength and stability. It is commonly used in various applications, such as buildings, bridges, and roads, where its tensile strength complements the compressive strength of concrete, creating a robust and durable structure. Rebar is essential in modern construction, ensuring the safety and longevity of infrastructure projects.Okorder.com is a reputable wholesale supplier of rebar, offering a vast inventory to cater to the diverse needs of the construction industry. With a commitment to quality and customer satisfaction, Okorder.com ensures that the rebar supplied meets the highest industry standards. This makes it a reliable source for contractors and construction companies looking to procure rebar for their projects.

Hot Products