Hot Rolled Steel Rebar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 800000TONS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Hot Rolled Steel Rebar:

Standard | GB UK USA | HRB335 HRB400 HRB500 G460B, B500A, B500B,B500C GR40, GR60 | |

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Price | Keep lower operating costs so as to offer competitive price for our clients | ||

Delivery Detail | within 45 days after received advanced payment or LC. | ||

Application | mainly used in construction industry to reinforce concrete structures and so on | ||

Invoicing | Actual or Theoretical Weight Basis as buyer’s request. | ||

Type | Hot rolled steel rebar | ||

Brand name | DRAGON | ||

Theoretical weight and section area of each diameter as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m (kg) | Pcs/ton |

6 | 28.27 | 0.222 | 2.664 | 375.38 |

8 | 50.27 | 0.395 | 4.74 | 210.97 |

10 | 78.54 | 0.617 | 7.404 | 135.06 |

12 | 113.1 | 0.888 | 10.656 | 93.84 |

14 | 153.9 | 1.21 | 14.52 | 68.87 |

16 | 201.1 | 1.58 | 18.96 | 52.74 |

18 | 254.5 | 2.00 | 24 | 41.67 |

20 | 314.2 | 2.47 | 29.64 | 33.74 |

22 | 380.1 | 2.98 | 35.76 | 27.96 |

25 | 490.9 | 3.85 | 46.2 | 21.65 |

28 | 615.8 | 4.83 | 57.96 | 17.25 |

32 | 804.2 | 6.31 | 75.72 | 13.21 |

36 | 1018 | 7.99 | 98.88 | 10.43 |

40 | 1257 | 9.87 | 118.44 | 8.44 |

50 | 1964 | 15.42 | 185.04 | 5.40 |

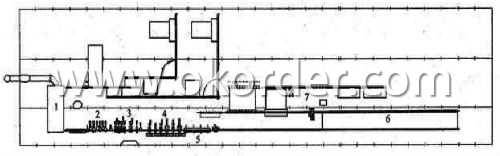

The production process of Steel Rebar

1-Waling beam furnace 2-Roughing rolling group 3-Intermediate rolling train

4-Finishing rolling group 5-Water-cooling device 6-Walking beam cooler

7-Finishing equipment(including the cold scale shear,short feet collection system,

automatic counting device,bundling machine, collect bench)

Usage and Applications of Hot Rolled Steel Rebar:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of Hot Rolled Steel Rebar:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment terms: TT payment in advance or Irrevocable LC at sight.

Trade terms :FOB, CFR, CIF

Label:to be specified by customer, generally, each bundle has 1-2 labels

Steel Rebar in stock

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

- Q: Can steel rebars be used in energy-efficient buildings?

- Certainly! Energy-efficient buildings can indeed incorporate steel rebars. These rebars are commonly utilized in the construction of reinforced concrete structures, including those that prioritize energy efficiency. Energy-efficient buildings aim to decrease energy consumption and minimize their environmental footprint. Although steel is a material with high embodied energy, meaning it requires a substantial amount of energy for production, it boasts numerous advantages for energy-efficient buildings. To begin with, steel rebars lend structural strength to reinforced concrete, enabling the creation of robust and long-lasting structures. This is pivotal for energy-efficient buildings, as their goal is to have an extended lifespan and reduced maintenance requirements, thereby lessening their overall environmental impact. Additionally, steel rebars can be employed in the construction of energy-efficient building components, such as insulated concrete forms (ICFs) and precast concrete panels. These building systems possess exceptional thermal insulation properties, which decrease heat transfer and enhance energy efficiency. Steel rebars are utilized to reinforce these components, ensuring their structural integrity. Furthermore, the thermal mass characteristics of concrete, reinforced by steel rebars, can contribute to a building's energy efficiency. Concrete has the capability to absorb and store heat, aiding in the regulation of indoor temperatures and reducing the need for excessive heating or cooling. Consequently, this can result in significant energy savings throughout a building's lifespan. It is important to note that the energy efficiency of a building is contingent upon various factors, including insulation, window design, HVAC systems, and the integration of renewable energy. While steel rebars play a vital role in reinforced concrete structures, their impact on overall energy efficiency should be evaluated in conjunction with other design choices and building materials.

- Q: Are there any standards or codes for steel rebars?

- Yes, there are indeed standards and codes for steel rebars. These standards and codes are essential to ensure the quality, safety, and compatibility of steel rebars used in various construction projects. One of the most widely recognized standards for steel rebars is the ASTM A615/A615M - Standard Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement. This standard provides specific requirements for the physical and mechanical properties of steel rebars, such as chemical composition, yield strength, tensile strength, elongation, and bendability. It also includes guidelines for marking, packaging, and testing of rebars. In addition to ASTM A615/A615M, there are other relevant standards and codes used in different countries and regions. For example, in Europe, the European Standard EN 10080 - Steel for the Reinforcement of Concrete provides specifications for steel rebars, including dimensions, tolerances, and mechanical properties. Similarly, the British Standard BS 4449 - Steel for the Reinforcement of Concrete is widely used in the United Kingdom. These standards and codes not only ensure consistency in the manufacturing and production of steel rebars but also help architects, engineers, and construction professionals select the appropriate rebars for their projects. Compliance with these standards is crucial to guarantee the structural integrity, durability, and safety of reinforced concrete structures. It is important for stakeholders in the construction industry to be familiar with the relevant standards and codes for steel rebars and to consistently adhere to them. This helps to maintain high-quality construction practices and prevent potential failures or accidents due to substandard materials.

- Q: What are the guidelines for proper spacing and lapping of steel rebars in concrete structures?

- The guidelines for proper spacing and lapping of steel rebars in concrete structures vary depending on the specific design and structural requirements. However, some general recommendations exist. The rebars should be adequately spaced to ensure proper concrete cover, allowing for corrosion protection and sufficient bond strength. Typically, the minimum spacing between parallel rebars is around 1.5 times the diameter of the larger bar or 25 mm (1 inch), whichever is greater. Lapping, or overlapping, of rebars is necessary to create a continuous load path. The length of the overlap depends on the design and the type of rebar connection being used. It is important to follow the specifications provided by structural engineers and adhere to local building codes to ensure the proper spacing and lapping of rebars in concrete structures.

- Q: What are the safety precautions to be followed while working with steel rebars?

- To prevent accidents and injuries while working with steel rebars, it is essential to adhere to specific safety measures. Consider the following precautions: 1. Personal Protective Equipment (PPE): Ensure that you always wear suitable PPE, including safety glasses, gloves, hard hats, and steel-toed boots. These items will shield you from potential dangers like falling objects, sharp edges, and flying debris. 2. Training and Knowledge: Before handling steel rebars, make sure you have undergone proper training and understand the associated safety protocols. Familiarize yourself with the equipment used and comprehend the potential risks involved. 3. Proper Lifting Techniques: Handling steel rebars can be challenging due to their weight and awkward shape. Always utilize correct lifting techniques, such as bending your knees and using your legs instead of your back. Do not attempt to lift a rebar that exceeds your capacity; seek assistance if necessary. 4. Secure Storage: Store steel rebars in a designated area that is free from potential obstructions. Stack them in a stable manner to prevent toppling and causing injuries. 5. Safe Handling: When moving steel rebars, exercise caution due to their sharp edges and potential for harm. Employ appropriate lifting equipment, such as cranes or forklifts, if required. Avoid dragging or sliding rebars, as this can lead to strains or sprains. 6. Fall Protection: If working at heights or near open edges, ensure that adequate fall protection measures are in place. This may involve using guardrails, safety harnesses, or safety nets to prevent falls. 7. Fire Safety: Steel rebars can become extremely hot when exposed to heat or flames. Ensure that appropriate fire prevention measures are in place, such as fire extinguishers, and exercise caution when working near flammable materials. 8. Communication: Maintain clear communication with colleagues and supervisors to ensure everyone is aware of their surroundings and potential hazards. Utilize hand signals or radios when working in noisy environments. 9. Regular Inspections: Routinely inspect steel rebars for any defects, such as cracks or sharp edges, that could pose a safety risk. Immediately remove any damaged or faulty rebars from use. 10. First Aid and Emergency Procedures: Familiarize yourself with first aid procedures and emergency protocols in the event of accidents or injuries. Have a well-stocked first aid kit readily available on-site and know the location of the nearest medical facility. By adhering to these safety precautions, you can minimize the likelihood of accidents and injuries while working with steel rebars. Always prioritize your safety and the safety of those around you.

- Q: How do steel rebars affect the overall fire resistance of concrete structures?

- Steel rebars can significantly improve the fire resistance of concrete structures. The high thermal conductivity of steel helps in dissipating heat away from the concrete, preventing rapid temperature rise and structural failure. Additionally, the presence of rebars enhances the load-bearing capacity of the structure during a fire, enabling it to withstand the intense heat for a longer duration before collapsing.

- Q: How do steel rebars prevent corrosion in concrete structures?

- Passivation is a crucial process in preventing corrosion in concrete structures, and steel rebars are the key components responsible for this. By forming a thin oxide layer on their surface, the rebars act as a barrier against corrosion-causing agents. When embedded in concrete, steel rebars benefit from the alkaline environment created by the cement paste, which aids in passivation. The concrete's high pH level prompts the formation of a protective layer of iron oxide, effectively shielding the rebars from moisture and oxygen. Moreover, well-constructed concrete possesses a dense and impermeable nature that restricts the movement of water and other corrosive substances towards the rebars. Consequently, the likelihood of corrosion initiation and progression is significantly reduced. In addition to the alkaline environment and concrete's impermeability, steel rebars are commonly coated with epoxy or zinc, providing an extra layer of protection. These coatings enhance the steel's resistance to corrosion, especially in aggressive environments like marine or chloride-rich conditions. To ensure the long-term prevention of corrosion in concrete structures, regular maintenance and preventive measures are essential. Proper concrete cover over the rebars and the avoidance of excessive moisture or chloride ions are crucial factors in this regard.

- Q: How do steel rebars contribute to the overall structural integrity of a building?

- Steel rebars, also known as reinforcement bars, play a crucial role in enhancing the overall structural integrity of a building. They are embedded within concrete structures to provide tensile strength, which complements the compressive strength of the concrete. By resisting tension forces, steel rebars help prevent cracks and failure in the concrete, ensuring the structural stability and durability of the building.

- Q: How do steel rebars contribute to the sustainability of a building?

- There are several ways in which steel rebars contribute to the sustainability of a building. To begin with, the utilization of steel rebars in reinforced concrete structures enhances the overall strength and durability of the building, thus extending its lifespan. This, in turn, reduces the frequency of repairs or replacements, resulting in less material consumption and waste generation over time. Moreover, steel rebars are manufactured from recycled materials, with a significant proportion being derived from scrap metal. This helps to decrease the demand for new steel production, which is an energy-intensive process and contributes to carbon emissions. By making use of recycled steel rebars, buildings can significantly reduce their carbon footprint and conserve natural resources. Furthermore, steel rebars aid in improving the structural integrity of the building, making it more resistant to various external forces such as earthquakes, hurricanes, and other natural disasters. This increased resilience decreases the potential for catastrophic damage and the subsequent need for major reconstruction or demolition, thus saving both resources and costs. Additionally, the utilization of steel rebars allows for the construction of taller and more open spaces, enabling efficient use of the building's footprint. This is particularly relevant in urban areas where land availability is limited. By enabling the construction of taller buildings, steel rebars contribute to urban densification, which helps to reduce urban sprawl and preserve natural habitats. Lastly, steel rebars are highly recyclable at the end of their service life. When a building is demolished, the steel rebars can be easily extracted and recycled, avoiding the accumulation of construction waste in landfills. The recycling of steel rebars saves energy and reduces the need for extracting and processing new materials, further contributing to the sustainability of the construction industry. In conclusion, steel rebars play a crucial role in enhancing the sustainability of a building by increasing its durability, utilizing recycled materials, improving structural resilience, enabling efficient land use, and facilitating the recycling of materials at the end of a building's life cycle.

- Q: What are the different methods of connecting steel rebars together?

- There are several different methods of connecting steel rebars together, depending on the specific requirements of the construction project. Some of the most common methods include: 1. Lap Splicing: This involves overlapping two rebars and then securing them together using steel wire or steel bars. It is a simple and cost-effective method but requires a longer length of rebars. 2. Mechanical Splicing: In this method, a mechanical coupler is used to connect two rebars together. The coupler is usually a sleeve or a collar that is attached to the ends of the rebars, providing a strong and reliable connection. Mechanical splicing is faster and more efficient than lap splicing, and it also allows for flexibility in positioning the rebars. 3. Welding: Welding is another method of connecting steel rebars, where the ends of the rebars are heated and fused together using an electric arc. This creates a strong and permanent connection. However, welding requires skilled labor and can be time-consuming and costly. 4. Threaded Couplers: Threaded couplers are similar to mechanical splicing, but instead of using a sleeve or collar, the rebars are threaded at the ends and then connected using a threaded coupler. This method provides a strong and reliable connection and is often used in larger construction projects. 5. Grout Sleeve Splicing: This method involves placing a grout-filled sleeve between two rebars to create a connection. The grout provides additional strength and stability to the joint. Grout sleeve splicing is commonly used in seismic zones or areas where high strength and ductility are required. 6. Reinforcing Bar Couplers (RBC): RBC is a proprietary method of connecting rebars, where a threaded sleeve is used to connect the rebars. The sleeve is filled with epoxy resin to create a strong bond. RBC offers high load capacity, ease of installation, and resistance to corrosion. It is important to consult with structural engineers and follow building codes and regulations to determine the most appropriate method of connecting steel rebars for a specific construction project.

- Q: What is the role of steel rebars in the construction of foundations?

- Steel rebars play a crucial role in the construction of foundations by providing reinforcement and strength to the concrete. They are used to reinforce the concrete and prevent it from cracking or collapsing under the weight and pressure of the structure. The rebars help distribute the load evenly, enhancing the structural integrity and stability of the foundation.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 500 Million |

| Main Markets | Southeast Asia; East Asia; Middle east |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 40%-60% |

| No.of Employees in Trade Department | 21-60 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 850,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM service offered |

| Product Price Range | high; average |

Send your message to us

Hot Rolled Steel Rebar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 800000TONS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords