Five mm Cold Rolled Steel Rebars in Coils with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Five mm Cold Rolled Steel Rebars in Coils with High Quality:

Name | Five mm Cold Rolled Steel Rebars in Coils with High Quality | |

Diameter | 5mm, 5.5mm, 6mm, 6.5mm, 7mm, 8mm, 9mm, 10mm, 11mm, 12mm, | |

Length | 6M, 9M, 12M or as required | |

Price | Keep lower operating costs so as to offer competitive price for our clients | |

Label | to be specified by customer, generally, each bundle has1-2 labels | |

Application | Building, construction | |

Invoicing | Actual or Theoretical Weight Basis as buyer’s request. | |

2. Theoretical weight and section area of each diameter of Five mm Cold Rolled Steel Rebars in Coils with High Quality as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | ||

5 | 19.6 | 0.154 | ||

3. Packaging & Delivery of Five mm Cold Rolled Steel Rebars in Coils with High Quality:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment terms: TT payment in advance or Irrevocable LC at sight.

Trade terms :FOB, CFR, CIF

Delivery Detail: within 45 days after received advanced payment or LC.

4. FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 month days from the beginning of production.

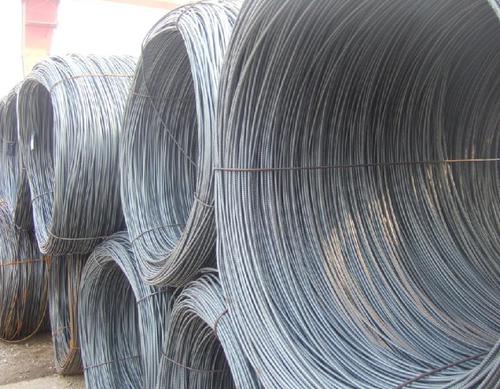

5. Images of Five mm Cold Rolled Steel Rebars in Coils with High Quality:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: How are steel rebars bundled and tied together on construction sites?

- Steel rebars, which are commonly used in construction sites to reinforce concrete structures, are bundled and tied together using a specific technique called rebar tying. This process ensures that rebars remain secure and in place during concrete pouring and other construction activities. To bundle rebars, construction workers typically gather a predetermined number of rebars, depending on the project's requirements, and align them parallel to each other. They then use wire or steel straps to tightly bind the rebars together, forming a bundle. The wire or steel straps are wrapped around the rebars at regular intervals, ensuring that the bundle remains compact and the rebars do not shift or separate. Once the rebars are bundled, they are further secured by tying them together using specialized tools. The most common tool used for rebar tying is a rebar tying gun or a rebar tier. This tool automates the process of tying rebars by quickly and efficiently twisting wire around the rebars, creating tight and secure connections. Rebar tying guns or tiers are equipped with a spool of wire that is fed through the tool. The construction worker simply positions the tool over the rebars, presses a trigger or button, and the tool automatically twists the wire around the rebars, tying them together. This process is repeated at regular intervals along the length of the rebars to ensure that they are securely fastened together. The type of wire used for rebar tying is typically a thin, high-tensile steel wire that is strong enough to withstand the forces exerted on the rebars during construction. This wire is specifically designed for rebar tying and is available in pre-cut lengths or on spools. Overall, the bundling and tying of steel rebars on construction sites is a crucial step in ensuring the structural integrity of concrete structures. The use of wire or steel straps, along with specialized rebar tying tools, allows construction workers to create secure and tightly bound bundles of rebars, preventing any movement or separation during construction activities.

- Q: What are the main uses of threaded steel?

- The rebar is a kind of small section steel, mainly used for the skeleton of reinforced concrete construction members. Steel is usually used for reinforced concrete, its role is to increase the friction fringe, the rebar and concrete secant integrally formed together, tic phenomenon can not occur in the role of external force, improve the strength of concrete.

- Q: How do steel rebars improve the flexural strength of concrete?

- Steel rebars improve the flexural strength of concrete by providing tensile strength, which is typically lacking in concrete. The rebars act as reinforcement, absorbing the tension forces that occur when the concrete is subjected to bending or flexing. This combination of concrete and steel rebars creates a composite material that is stronger and more resistant to cracking or breaking under flexural loads.

- Q: How do steel rebars reinforce concrete?

- Steel rebars reinforce concrete by providing additional strength and stability to the structure. When concrete is poured, it is strong in compression but weak in tension. Steel rebars are embedded within the concrete to counterbalance this weakness and enhance its tensile strength. The rebars act as a reinforcement by absorbing the tensile forces that occur when a structure is subjected to bending or stretching. When such forces are applied, the rebars distribute the load across the concrete, preventing cracks and failure. This is crucial in structures such as buildings, bridges, and dams, where the concrete needs to withstand various external forces. The rebars also help to control the expansion and contraction of the concrete due to temperature changes. Since steel has a similar coefficient of thermal expansion as concrete, it helps to minimize the stress that occurs due to temperature fluctuations, reducing the risk of cracking. Moreover, the bond between the steel rebars and the concrete is essential for effective reinforcement. The rough surface of the rebars provides an excellent grip with the surrounding concrete, ensuring that they work together as a composite material. This bond enables the transfer of stress from the concrete to the rebars, enhancing the overall strength and durability of the structure. In summary, steel rebars reinforce concrete by adding tensile strength, distributing loads, controlling temperature-induced stress, and creating a strong bond with the concrete. This combination of concrete and steel creates a reinforced concrete structure that can withstand various external forces and maintain its structural integrity over time.

- Q: How do steel rebars affect the overall thermal performance of a structure?

- Steel rebars have a minimal impact on the overall thermal performance of a structure. Since steel is a good conductor of heat, it allows for efficient transfer of thermal energy, but rebars typically constitute a small fraction of the overall mass of a building. Therefore, their influence on the thermal behavior of the structure is relatively insignificant compared to other factors such as insulation materials, windows, and overall building design.

- Q: What are the common manufacturing processes for steel rebars?

- The common manufacturing processes for steel rebars involve several steps to ensure the production of high-quality and durable reinforcement bars. These processes typically include: 1. Melting: The first step in manufacturing steel rebars is melting the raw materials, which usually consist of iron ore, coal, and limestone, in a blast furnace. This process produces molten iron that is then further refined to remove impurities. 2. Casting: Once the molten iron is refined, it is poured into molds to create large billets or blooms. These molds are often called continuous casting machines, where the molten iron solidifies into a rectangular shape. 3. Rolling: The solidified billets or blooms are then heated and passed through rolling mills. The rolling process involves compressing the steel between a series of rollers to reduce its thickness and shape it into the desired dimensions of rebars. This process also helps improve the mechanical properties and eliminate any internal defects or impurities. 4. Quenching and Tempering: After the initial rolling process, the rebars may undergo quenching and tempering. Quenching involves rapidly cooling the steel bars by immersing them in water or oil. This step increases the hardness of the rebars, making them more resistant to deformation and wear. Tempering follows, which involves reheating the quenched bars to a specific temperature and then cooling them slowly. Tempering helps remove internal stresses and improves the toughness of the rebars. 5. Cutting and Coiling: Once the bars have been rolled and heat-treated, they are cut to the desired lengths using cutting machines. The cut rebars are then coiled into bundles or stacked for storage and transportation. 6. Surface Treatment: To enhance the corrosion resistance of rebars, manufacturers often apply a protective coating or surface treatment. This can involve hot-dip galvanizing, where the rebars are immersed in molten zinc to form a zinc coating, or epoxy coating, where a layer of epoxy resin is applied to the rebars. It is important to note that these manufacturing processes may vary depending on the specific requirements and standards set by different countries and industries. However, the aforementioned steps provide a general overview of the common processes involved in manufacturing steel rebars.

- Q: What is the impact of steel rebars on the overall maintenance of a building?

- The overall maintenance of a building is significantly influenced by steel rebars. These reinforced steel bars are widely used in construction to provide strength and stability to concrete structures. The presence of rebars improves the building's structural integrity, making it more resistant to external forces like earthquakes, wind, and heavy loads. Using steel rebars has several key benefits, one of which is their ability to prevent cracking and minimize structural failures. By reinforcing the concrete, rebars evenly distribute the load, reducing stress on the building. This helps prevent the formation and spread of cracks that can compromise the structural stability and result in costly repairs. Additionally, steel rebars play a crucial role in increasing the durability and lifespan of a building. They add strength to the concrete, making it more resistant to wear and tear over time. This means less frequent maintenance and repairs, leading to cost savings for the owners. When it comes to maintenance, properly installed steel rebars require minimal attention. However, regular inspection and maintenance are necessary to ensure their continued effectiveness. This includes checking for signs of corrosion, which can weaken the rebars and compromise the building's structural integrity. Protective coatings or regular cleaning can be used to prevent corrosion and extend the rebars' lifespan. In conclusion, steel rebars have a positive impact on a building's overall maintenance. They enhance structural integrity, prevent cracking, and increase durability, resulting in reduced maintenance needs and a longer lifespan. Regular inspection and maintenance of rebars are crucial to ensure effectiveness and mitigate potential issues such as corrosion.

- Q: How are steel rebars classified based on their shapes?

- Steel rebars are classified based on their shapes into different categories such as round, square, deformed, and flat rebars.

- Q: Can steel rebars be used in railway and metro construction?

- Yes, steel rebars can be used in railway and metro construction. Steel rebars are commonly used in reinforced concrete structures, including railway tracks and metro platforms, to provide strength and stability to the construction. They are essential for ensuring the durability and longevity of these infrastructure projects.

- Q: What is the typical lead time for ordering steel rebars?

- The lead time for ordering steel rebars can vary depending on various factors, such as the quantity required, the specific grade and size needed, and the availability and location of the supplier. Typically, if the rebars are readily available and in stock, the lead time can range from a few days to a couple of weeks, assuming the supplier has the necessary inventory and transportation logistics are straightforward. However, if the rebars require special manufacturing or are in high demand, the lead time can be longer. In such cases, it may take several weeks or even months to receive the rebars, especially for large or custom orders that involve special fabrication processes or if the supplier is facing production constraints. To obtain a more accurate estimate of the lead time, it is important to communicate with the supplier and provide them with all the necessary project requirements. It is also advisable to plan ahead and place the order well in advance, particularly for projects with strict deadlines, to ensure the timely arrival of the rebars.

Send your message to us

Five mm Cold Rolled Steel Rebars in Coils with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords