G460B deformed steel bar deformed steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering G460B deformed steel bar deformed steel bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

G460B deformed steel bar deformed steel bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's deformed steel bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of HRB400 Deformed Steel Bar:

Standard | GB | HRB400 | |

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Place of origin | Hebei, China mainland | ||

Advantages | exact size, regular package, chemical and mechanical properties are stable. | ||

Type | Hot rolled deformed steel bar | ||

Brand name | DRAGON | ||

Chemical Composition: (Please kindly find our chemistry of our material based on HRB500 as below for your information)

Grade | Technical data of the original chemical composition (%) | ||||||

C | Mn | Si | S | P | V | ||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physical capability | |||||||

Yield Strength (N/cm²) | Tensile Strength (N/cm²) | Elongation (%) | |||||

≥400 | ≥570 | ≥14 | |||||

Theoretical weight and section area of each diameter as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m bar(kg) |

6 | 28.27 | 0.222 | 2.664 |

8 | 50.27 | 0.395 | 4.74 |

10 | 78.54 | 0.617 | 7.404 |

12 | 113.1 | 0.888 | 10.656 |

14 | 153.9 | 1.21 | 14.52 |

16 | 201.1 | 1.58 | 18.96 |

18 | 254.5 | 2.00 | 24 |

20 | 314.2 | 2.47 | 29.64 |

22 | 380.1 | 2.98 | 35.76 |

25 | 490.9 | 3.85 | 46.2 |

28 | 615.8 | 4.83 | 57.96 |

32 | 804.2 | 6.31 | 75.72 |

36 | 1018 | 7.99 | 98.88 |

40 | 1257 | 9.87 | 118.44 |

50 | 1964 | 15.42 | 185.04 |

Usage and Applications of HRB400 Deformed Steel Bar:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of HRB400 Deformed Steel Bar:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment term: TT or L/C

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

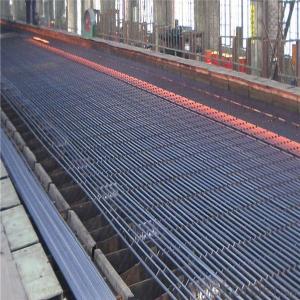

Deformed Steel Bar in container

Deformed Steel Bar in factory

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: Can steel rebars be used in other applications besides construction?

- Yes, steel rebars can be used in other applications besides construction. They are commonly utilized in various industries such as automotive, manufacturing, and infrastructure projects, where their high strength and durability make them suitable for reinforcement purposes. Additionally, steel rebars can also be employed in sculptures, art installations, and DIY projects due to their malleability and versatility.

- Q: Can steel rebars be used in the construction of offshore oil platforms?

- Yes, steel rebars can be used in the construction of offshore oil platforms. Steel rebars are commonly used in construction to reinforce concrete structures and provide additional strength and durability. In the case of offshore oil platforms, steel rebars are used to reinforce the concrete foundations and structures of the platform, helping to withstand the harsh environmental conditions and the weight of the equipment and infrastructure on the platform. The steel rebars are designed to resist corrosion and are typically coated with epoxy or other protective coatings to prevent rusting in the corrosive marine environment. Additionally, steel rebars can be custom-designed to meet the specific requirements of the offshore oil platform, ensuring they provide the necessary strength and stability.

- Q: What is the corrosion resistance of steel rebars?

- The corrosion resistance of steel rebars is generally high due to the presence of a protective oxide layer on the surface of the steel. However, in certain environments, such as those with high levels of moisture or exposure to corrosive substances, the rebars may be susceptible to corrosion. Therefore, additional measures such as proper concrete cover, epoxy coating, or galvanization are often employed to enhance the corrosion resistance of steel rebars.

- Q: What are the different coating options available for steel rebars?

- There are several coating options available for steel rebars, including epoxy, zinc, and polyethylene. Epoxy coating provides corrosion resistance and is commonly used in harsh environments. Zinc coating, such as hot-dip galvanizing, offers excellent protection against corrosion and is often used in marine applications. Polyethylene coating provides a barrier against moisture and chemicals, making it suitable for applications where corrosion resistance is a priority.

- Q: What is the difference between deformed and plain steel rebars?

- Deformed steel rebars have ridges, ribs, or indentations on their surface, which provides better bonding with concrete and enhances the overall strength and stability of reinforced concrete structures. Plain steel rebars, on the other hand, have a smooth surface without any deformations. The presence of deformations in deformed rebars increases their resistance to slippage, making them more suitable for applications where preventing concrete from cracking or slipping is crucial, such as in high-rise buildings, bridges, and heavy-duty construction projects.

- Q: What is the role of steel rebars in dam construction?

- The role of steel rebars in dam construction is to reinforce and strengthen the concrete structure of the dam. Rebars are embedded within the concrete to provide additional tensile strength, preventing cracks and enhancing the overall structural integrity of the dam.

- Q: What is the recommended method for splicing steel rebars together?

- The recommended method for splicing steel rebars together is typically achieved through mechanical splicing techniques, such as using couplers or mechanical connectors. These methods ensure a reliable and efficient connection between rebars, providing structural integrity and reinforcing strength to the construction project.

- Q: How are steel rebars protected against electromagnetic interference?

- Steel rebars are typically protected against electromagnetic interference through the use of concrete cover. The concrete acts as a shield, preventing electromagnetic waves from interfering with the steel rebars. Additionally, proper grounding and bonding techniques are employed to further enhance protection against electromagnetic interference.

- Q: How do steel rebars affect the overall vibration control of a structure?

- Steel rebars can significantly enhance the overall vibration control of a structure. By reinforcing the concrete, rebars increase the structural stiffness and strength, reducing the amplitude of vibrations. They also help distribute and dissipate energy from dynamic loads, thus minimizing the risk of structural failure and enhancing the overall stability. Additionally, rebars can improve the damping characteristics of a structure, reducing the resonant frequencies and attenuating vibrations. Overall, the presence of steel rebars in a structure plays a crucial role in enhancing its vibration control capabilities.

- Q: Can steel rebars be used in coastal construction?

- Yes, steel rebars can be used in coastal construction. Steel rebars are commonly used in construction projects, including in coastal areas where they provide crucial reinforcement to concrete structures. The steel rebars are typically coated or treated to prevent corrosion from the saltwater and other coastal elements, ensuring their durability and longevity in coastal environments.

Send your message to us

G460B deformed steel bar deformed steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords