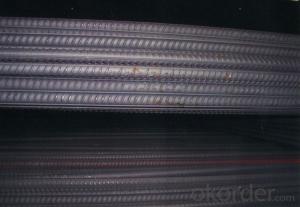

HRB500 hot rolled ribbed steel bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Definition

That is the new standard name for HRB500 steel, grade four steel as the old name, as a kind of hot rolled ribbed bar. In the construction industry, four screw steel is the old saying.

Hot rolled ribbed steel grades by HRB and number of yield points minimumcomposition. H, R, B respectively (Hotrolled), hot rolled ribbed steel bar(Ribbbed), (Bars) the three word's first letter English.

Classification

Hot rolled ribbed steel bar is divided into HRB335 (the old number is 20MnSi),HRB400 (the old No. 20MnSiV, 20MnSiNb, 20Mnti), HRB500 three brands.

Hot rolled bars of fine grains in the grades of hot rolled ribbed bar after Englishabbreviation "fine" English (Fine) the first letter. Such as: HRBF335, HRBF400,HRBF500.

A suitable grade higher requirements for seismic structures: add E in the existing brands after (for example: HRB400E, HRBF400E

The main purposes

HRB500 grade steel in strength, ductility, high temperature resistance, low temperature performance and seismic performance and fatigue performanceare better than HRB400 has greatly improved, mainly used in high-rise and super high-rise building, long span bridges, high standards of construction, is an international engineering standards recommended actively and has been widely used in developed countries products, it shows that the application ofpractice HRB500 steel works, can save a lot of steel, and has obvious economic benefit and social benefit.

The main origin

Screw thread steel producers in China are mainly distributed in North and northeast, North China area such as Shougang, Tang Gang, Xuan Steel,bearing steel, Shanxi Zhongyang steel plant, Baoding Purui the steel, the northeast area such as resistant, Tai, realize, these two areas account for about 50% of the total output in the screw thread steel.

The difference between the screw thread steel and round steel bar is provided with longitudinal ribs and transverse ribs surface, usually with two longitudinalribs and transverse ribs along the length direction of the uniform distribution.Screw thread steel belongs to the small steel steel, mainly used in reinforced concrete building components of the skeleton. In use requires a certainmechanical strength, bending deformation properties and process of welding performance. Screw thread steel billet production raw material for the carbon structure steel smelting processing sedation or low alloy structural steel,finished steel for hot rolling, normalizing or hot-rolled state of delivery.

Advantage

Nationwide, the annual if 20000000 t two screw thread steel is four level(HRB500) to replace, can save more than 5000000 t screw thread steeldosage. Equivalent to an annual consumption of iron ore 4000000 ~800 million T, save standard coal 1670000 ~335 million T, less consumption of fresh water 9600000 ~1740 million m3, to reduce dust emissions of sulfur dioxide emissions reduction of 750~1500t, 625~1250t, energy saving and emission reduction effectiveness is huge, consistent with the low carbon environmental protection concept of current international society pay more and more attention.

The promotion of the work

In order to make better performance, more economical and four screw steelproducts of low carbon environmental protection at home and rapidly applied,gradually to replace the two screw steel low level, should do the following aspects of work:

1 wide publicity to introduce four screw steel composition, properties and their own advantages, strengthen the construction design institute relevant indexes of four screw steel chemical composition, mechanical properties and welding performance of the understanding, promote the use of the design of the construction project, to lay a solid foundation for the four screw steel market promotion.

Each of the 2 key projects on strengthening highway, railway, bridge, and a series of infrastructure projects, do a good job of key projects of the bidding work, the realization of the four screw steel supply breakthrough from thelarge-scale key projects, the formation of a demonstration effect on other common construction project and the real estate industry, and graduallypenetrated into all fields of thread steel application, so as to fully replace thelow grade screw thread steel.

- Q: 8 mm thread steel, how much is a bundle?

- The raw steel billet for the production of threaded steel is carbon structural steel or low alloy structural steel which is treated by calm melting, and the finished steel bar is delivered in hot rolling forming, normalizing or hot rolling state.

- Q: 10 less than three rebar refers to the rebar?

- Grade steel HPB235, grade three steel, HRB400. Where P represents light circle, and R indicates rib (thread).Numbers indicate the degree of flexion (which can be regarded as strength). Is that clear?

- Q: How are steel rebars stored and handled on construction sites?

- Steel rebars are typically stored in designated areas on construction sites to ensure easy access and organization. They are often stacked horizontally and secured with supports to prevent them from rolling or falling. When handling rebars, workers wear appropriate protective gear and use equipment such as cranes or forklifts to lift and move them safely. Additionally, rebars are carefully inspected for any defects or damages before being used in construction projects.

- Q: Are steel rebars suitable for use in structures with high wind loads?

- Structures with high wind loads can benefit from the use of steel rebars. Also known as reinforcing bars, steel rebars are commonly utilized in construction to provide strength and stability to reinforced concrete structures. Their purpose is to withstand significant tensile forces and play a crucial role in maintaining the structural integrity of buildings, particularly in areas prone to high wind loads. Steel rebars possess several advantages that render them suitable for structures with high wind loads. Firstly, steel exhibits exceptional tensile strength, enabling it to resist the forces generated by wind loads. Unlike materials such as timber or concrete, steel rebars possess remarkable ductility, allowing them to absorb and redistribute the energy produced by wind-induced vibrations. Secondly, steel rebars demonstrate remarkable durability and resistance to corrosion. This characteristic is vital for structures exposed to harsh weather conditions, including strong winds. Utilizing steel rebars mitigates the risk of structural deterioration or weakening over time caused by wind-induced stresses. Furthermore, steel rebars offer ease in molding and shaping, accommodating the specific design requirements of the structure. This flexibility empowers engineers to create and construct buildings capable of withstanding various wind loads experienced in different regions. In conclusion, due to their high tensile strength, durability, and resistance to corrosion, steel rebars are an ideal choice for structures with high wind loads. They provide the necessary reinforcement to ensure the longevity and safety of the structure under challenging wind conditions.

- Q: Can steel rebars be used in structures with high resistance to earthquakes?

- Yes, steel rebars can be used in structures with high resistance to earthquakes. Steel rebars are commonly used in reinforced concrete structures to enhance their strength and durability. In earthquake-prone areas, it is crucial to design and construct buildings that can withstand seismic forces. Steel rebars, when properly incorporated into the structural design, can help enhance the overall seismic performance of a building. Steel rebars provide several advantages in earthquake-resistant structures. Firstly, they increase the tensile strength of concrete, which is otherwise weak in tension. This reinforcement helps to prevent cracking and failure of the concrete during seismic events. Additionally, steel rebars can improve the ductility of the structure, allowing it to absorb and dissipate energy during an earthquake. This ductile behavior helps to minimize structural damage and ensures that the building remains stable and safe. Furthermore, steel rebars can be used in conjunction with other seismic design techniques to enhance the overall performance of the structure. For example, they can be combined with special concrete mixes, such as high-strength or fiber-reinforced concrete, to further improve the seismic resistance. Additionally, advanced structural systems like moment frames or shear walls can be integrated with steel rebars to provide even greater earthquake resistance. However, it is important to note that the earthquake resistance of a structure does not solely rely on the use of steel rebars. Proper design, construction techniques, and adherence to seismic building codes are also crucial factors. Engineers must consider various aspects such as the building's location, soil conditions, and expected seismic loads to ensure the structural integrity and safety of the building. In conclusion, steel rebars can be effectively used in structures with high resistance to earthquakes. Their inclusion in reinforced concrete structures enhances the tensile strength and ductility, enabling the building to withstand seismic forces. However, it is essential to implement comprehensive seismic design strategies and adhere to building codes to ensure the overall safety and performance of the structure.

- Q: Are steel rebars resistant to chemical attacks?

- The resistance of steel rebars to chemical attacks may vary depending on the specific chemicals they encounter, although they are typically resistant. Steel rebars are primarily composed of carbon steel, renowned for its exceptional strength and durability. Carbon steel exhibits good resistance to numerous common chemicals, including water, mild acids, and alkalis. Nevertheless, certain chemicals can pose a threat to steel rebars by inducing corrosion or deterioration. For instance, powerful acids like sulfuric acid or hydrochloric acid can swiftly corrode steel rebars. Furthermore, exposure to chlorides, such as those present in saltwater or deicing salts, can heighten the risk of corrosion in steel rebars. To bolster the resistance of steel rebars against chemical attacks, several protective measures can be implemented. One prevalent approach involves the application of protective coatings, such as epoxy or zinc, onto the rebars. These coatings create a barrier between the steel and the chemicals, preventing direct contact and reducing the likelihood of corrosion. In conclusion, although steel rebars generally exhibit resistance to chemical attacks, their resistance can be influenced by the specific chemicals they encounter. By implementing appropriate protective measures, their resistance can be enhanced, thus prolonging their lifespan in environments where chemical exposure is a concern.

- Q: How are steel rebars installed in foundations?

- Steel rebars are installed in foundations by first determining the required placement and configuration of the rebars based on engineering specifications. Once determined, the rebars are then placed and secured within the foundation's formwork, ensuring they are properly aligned and spaced according to the design requirements. Finally, the concrete is poured, encasing the rebars, and allowing them to provide reinforcement and strength to the foundation.

- Q: What are the different methods of joining steel rebars in a structure?

- The different methods of joining steel rebars in a structure include lap splicing, mechanical splicing, and welded splicing.

- Q: How do steel rebars prevent concrete structures from collapsing?

- Reinforcement and strength are provided to concrete structures by steel rebars, which prevent their collapse. Concrete is capable of withstanding forces that compress or squeeze it, making it a strong material. However, it is not able to withstand forces that pull it apart, resulting in weakness in tension. When subjected to tension, concrete may crack and ultimately fail. To counteract these tensile forces and offer additional strength, reinforcement bars, also known as steel rebars, are typically embedded within concrete structures. These rebars are made of high-strength steel and are strategically placed to resist the pulling forces. When external forces, such as wind or seismic activity, impact a concrete structure, the rebars assist in distributing the load and resisting tension. As the concrete attempts to separate, the rebars hold it together, preventing the propagation of cracks and maintaining the structure's integrity. Additionally, the rebars enhance the overall durability and lifespan of the concrete structure. By reinforcing the concrete, they mitigate the effects of shrinkage and thermal expansion, which can lead to cracks over time. Consequently, a more stable and resilient structure is achieved, capable of withstanding various environmental and structural stresses. In conclusion, steel rebars are crucial in averting the collapse of concrete structures, as they provide the necessary reinforcement and strength to resist tension. They elevate the structural integrity, durability, and safety of concrete structures, ensuring their ability to withstand demands and fulfill their intended purpose for extended periods.

- Q: Can steel rebars be used in the construction of shopping centers?

- Yes, steel rebars can be used in the construction of shopping centers. Steel rebars, also known as reinforcing bars, are commonly used in the construction industry to reinforce concrete structures. Shopping centers often require strong, durable, and long-lasting infrastructure, and steel rebars provide the necessary strength and reinforcement to support the weight and load of the building. They help to prevent cracks, increase structural stability, and enhance the overall durability of the construction. Additionally, steel rebars can be easily shaped and cut to fit the specific design requirements of a shopping center, making them a versatile and practical choice for construction projects.

Send your message to us

HRB500 hot rolled ribbed steel bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords