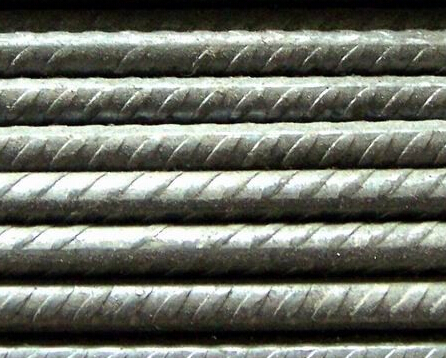

Deformed Steel Bar ASTM A615 GR40 GR60 with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Deformed Steel Bar ASTM A615 GR40 GR60 with High Quality at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Deformed Steel Bar ASTM A615 GR40 GR60 with High Quality are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Specifications of Deformed Steel Bar ASTM A615 GR40 GR60 with High Quality:

Standard | GB | HRB335, HRB400, HRB500 | |

UK | G460B, B500A, B500B,B500C | ||

USA | GR40, GR60 | ||

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Place of origin | Hebei, China mainland | ||

Application | building,construction,road,bridge etc | ||

Brand name | DRAGON | ||

Theoretical weight and section area of each diameter as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) |

6 | 28.27 | 0.222 |

8 | 50.27 | 0.395 |

10 | 78.54 | 0.617 |

12 | 113.1 | 0.888 |

14 | 153.9 | 1.21 |

16 | 201.1 | 1.58 |

18 | 254.5 | 2.00 |

20 | 314.2 | 2.47 |

22 | 380.1 | 2.98 |

25 | 490.9 | 3.85 |

28 | 615.8 | 4.83 |

32 | 804.2 | 6.31 |

36 | 1018 | 7.99 |

40 | 1257 | 9.87 |

50 | 1964 | 15.42 |

Usage and Applications of Deformed Steel Bar ASTM A615 GR40 GR60 with High Quality:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of Deformed Steel Bar:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment term: TT or L/C

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

Deformed Steel Bar in Coil

Produce Line of Deformed Steel Bar

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: What are the factors to consider when choosing steel rebars for a project?

- When choosing steel rebars for a project, some important factors to consider include the grade and quality of the steel, the rebar size and shape needed, the project requirements and specifications, the cost and availability of the rebars, and any specific environmental or corrosion resistance needs. Additionally, the steel rebars should comply with relevant industry standards and codes to ensure their suitability and performance in the project.

- Q: What are the factors that determine the selection of steel rebars?

- The selection of steel rebars for construction projects depends on several factors. Among these factors, the required strength and durability of the structure are of utmost importance. Different grades of steel rebars possess varying yield strengths, indicating their capacity to withstand stress before deformation occurs. The strength required for the rebars is determined by the design and load-bearing capacity of the structure. Another factor to consider is the corrosion resistance of the rebars. Steel rebars are prone to corrosion, especially when exposed to moisture and other environmental elements. In regions with high humidity or near coastal areas, it may be necessary to use corrosion-resistant rebars to ensure the project's longevity and structural integrity. The size and shape of the rebars also play a significant role in the selection process. The rebar's diameter is determined by structural requirements and the thickness of the concrete cover. Additionally, the rebar's shape, whether plain, deformed, or ribbed, affects its bonding with the surrounding concrete. Availability and cost are also important considerations. Certain regions may have easier access to specific grades or types of steel rebars, while others may require importing them. The cost of the rebars also influences the selection, as different grades and types have varying price points. Lastly, compliance with local building codes and regulations is crucial. These codes establish minimum standards for strength, corrosion resistance, and other factors that rebars used in construction must meet. Overall, the selection of steel rebars is determined by the required strength, corrosion resistance, size and shape, availability and cost, and compliance with local building codes and regulations. By considering these factors, engineers and construction professionals can choose the most suitable rebars for their projects, ensuring safety, durability, and cost-effectiveness.

- Q: What are the different types of coatings available for steel rebars to prevent corrosion?

- There are several types of coatings available for steel rebars to prevent corrosion. These coatings are designed to provide a protective barrier between the steel rebar and the surrounding environment, thereby preventing or minimizing the corrosion process. The different types of coatings include: 1. Epoxy Coating: This is a commonly used coating for steel rebars. It is a thermosetting polymer that forms a strong and durable protective layer. Epoxy coatings are known for their excellent resistance to chemicals and abrasion. 2. Zinc Coating: Zinc coatings, such as hot-dip galvanization, are widely used to protect steel rebars from corrosion. The zinc layer acts as a sacrificial anode, meaning it corrodes instead of the steel rebar, protecting it from oxidation. 3. Fusion-Bonded Epoxy Coating: This coating involves melting epoxy powder onto the steel rebar's surface, creating a strong bond. Fusion-bonded epoxy coatings are resistant to corrosion, chemicals, and moisture. 4. Polymer Coating: Polymer coatings, such as polyethylene or polypropylene, provide a protective layer against corrosion. These coatings are highly resistant to chemicals, abrasion, and moisture, ensuring long-term protection for the steel rebar. 5. Concrete Coating: Concrete can act as a protective coating for steel rebars when it is properly applied. The alkaline environment of concrete helps to passivate the steel rebar, forming a protective oxide layer that prevents further corrosion. 6. Stainless Steel Coating: Applying a thin layer of stainless steel onto the steel rebar's surface can significantly enhance its corrosion resistance. Stainless steel coatings offer excellent durability and resistance to harsh environments. It is important to choose the appropriate coating based on the specific application and environmental conditions to ensure optimal protection against corrosion for steel rebars.

- Q: What are the guidelines for reinforcing concrete slabs with steel rebars?

- When reinforcing concrete slabs with steel rebars, there are several important factors to consider. Firstly, the required amount of reinforcement must be determined based on the load that the slab will bear. This load can be calculated using structural engineering principles and taking into account factors such as the intended use of the slab, the weight of any equipment or vehicles that will be placed on it, and any applicable building codes or regulations. Once the necessary amount of reinforcement is determined, the next step is to design the layout of the rebars. This involves spacing them at specified intervals to ensure an even distribution of the load across the slab. The spacing will vary depending on the thickness of the slab, with thicker slabs generally requiring more rebars. It is also important to include minimum clearances between the rebars and the edges or bottom of the slab to prevent corrosion and ensure proper concrete cover. The size and type of rebars used is another important consideration. Commonly used types include plain round bars, deformed bars, or welded wire fabric. The diameter of the rebars and the grade of steel should be selected based on the expected load and the requirements of the project specifications or building codes. During the construction process, it is crucial to correctly place and secure the rebars within the formwork to maintain their intended position. This may involve using chairs, spacers, or other devices to ensure proper alignment and prevent displacement. Additionally, care should be taken to avoid damaging the rebars during the pouring and finishing of the concrete. Lastly, it is important to inspect and test the reinforced concrete slab to ensure that the rebars are properly installed and meet the required specifications. This can involve visual inspections, as well as non-destructive testing methods such as ultrasound or ground-penetrating radar to verify the integrity and position of the rebars. In conclusion, adhering to these guidelines for reinforcing concrete slabs with steel rebars will help guarantee the structural integrity and longevity of the slab, while also meeting necessary safety and building code requirements.

- Q: What are the factors to consider while designing a reinforced concrete structure with steel rebars?

- There are several factors to consider while designing a reinforced concrete structure with steel rebars. Firstly, the structural loads acting on the building, such as dead loads, live loads, and environmental loads, need to be carefully analyzed and considered. This analysis helps determine the appropriate size and spacing of the rebars. Secondly, the design must take into account the desired strength and durability of the structure. The type and grade of concrete, as well as the quality and corrosion resistance of the steel rebars, must be selected to ensure the desired lifespan and performance of the structure. Thirdly, the construction constraints and limitations, including the availability of materials and construction techniques, should be considered during the design stage. This helps ensure that the design is practical and feasible to implement. Lastly, it is crucial to adhere to the relevant building codes, regulations, and industry standards. These guidelines provide specific requirements and safety factors that must be followed to ensure the structural integrity and safety of the reinforced concrete structure with steel rebars.

- Q: How do steel rebars contribute to the overall stability of a bridge deck?

- Steel rebars contribute to the overall stability of a bridge deck by providing reinforcement and strength to the concrete structure. The rebars are embedded within the concrete, creating a composite material that is able to withstand the loads and stresses imposed on the bridge. This reinforcement helps to prevent cracking, bending, and failure of the bridge deck, ensuring its long-term durability and structural integrity.

- Q: How are steel rebars connected or joined together?

- Steel rebars are typically connected or joined together using different methods, depending on the specific application and structural requirements. The most common methods of connecting steel rebars are: 1. Overlapping: This method involves overlapping two rebars to create a continuous length of reinforcement. The overlapping length should meet the specified design requirements and is typically secured with steel tie wires or mechanical connectors. 2. Welding: Steel rebars can be joined together through welding, which involves melting the ends of the rebars and fusing them together using heat. Welding is a suitable method for connecting rebars in pre-fabricated structures or where high strength and durability are required. 3. Mechanical couplers: Mechanical couplers are pre-fabricated devices that provide a threaded connection between two rebars. These couplers are typically screwed onto the ends of the rebars, creating a strong and reliable connection. Mechanical couplers are commonly used in construction projects where fast installation and ease of use are important. 4. Lap splicing: Lap splicing involves connecting two rebars by overlapping them and securing the overlap with steel tie wires or mechanical connectors. This method is widely used in reinforced concrete structures and provides adequate strength and continuity. 5. Grouted splicing: In grouted splicing, the ends of two rebars are embedded into a sleeve or coupling filled with grout or epoxy resin. This method ensures a strong bond between the rebars, providing enhanced load transfer and corrosion resistance. It is important to note that the connection method used for steel rebars should comply with the applicable building codes and structural design specifications to ensure the overall integrity and safety of the structure.

- Q: Are steel rebars suitable for use in high-rise buildings?

- Yes, steel rebars are suitable for use in high-rise buildings. Steel rebars, also known as reinforcing bars, are commonly used in the construction industry to provide strength and stability to concrete structures. High-rise buildings require a strong and durable structural system to withstand various loads and forces such as wind, earthquakes, and the weight of the building itself. Steel rebars offer excellent tensile strength and ductility, making them ideal for reinforcing concrete in high-rise structures. One of the key advantages of steel rebars is their ability to resist tensile forces. Concrete is strong in compression but weak in tension, and steel rebars help counteract this weakness by providing the necessary tensile strength. This is crucial in high-rise buildings where the weight of the structure can cause tension on the concrete elements. By reinforcing the concrete with steel rebars, the overall structural integrity of the building is enhanced, ensuring its safety and stability. Additionally, steel rebars have superior ductility, which is the ability to deform under stress without fracturing. This property is essential in high-rise buildings as they are subject to dynamic loads and potential movements caused by factors like wind or seismic activity. Steel rebars can absorb and distribute these forces, reducing the risk of structural failure or collapse. Furthermore, steel rebars are readily available and cost-effective compared to alternative materials such as carbon fiber or fiberglass. They can be easily fabricated and installed in various shapes and sizes to fit the specific design requirements of high-rise buildings. However, it is important to note that the suitability of steel rebars in high-rise buildings also depends on proper design, installation, and regular maintenance. It is crucial to follow the relevant building codes and standards, ensure proper corrosion protection, and conduct regular inspections to detect any potential issues. By adhering to these practices, steel rebars can provide a reliable and durable reinforcement solution for high-rise buildings.

- Q: How do steel rebars affect the overall structural integrity of a building?

- Steel rebars play a crucial role in enhancing the overall structural integrity of a building. By reinforcing and strengthening concrete structures, rebars effectively distribute loads and resist tension, preventing cracks and structural failures. This reinforcement enables buildings to withstand various forces, such as earthquakes and high winds, ensuring their stability and durability over time.

- Q: How do steel rebars affect the overall safety of construction projects?

- Steel rebars play a crucial role in enhancing the overall safety of construction projects. Firstly, steel rebars provide reinforcement to concrete structures, making them stronger and more resistant to various types of forces such as tension, compression, and bending. This reinforcement significantly increases the structural integrity of buildings, bridges, and other constructions, reducing the risk of collapse or failure. Moreover, steel rebars have excellent ductility, meaning they can deform without fracturing under extreme loads. This property allows rebars to absorb and distribute the energy generated during earthquakes, high winds, or heavy impacts, preventing sudden and catastrophic structural failures. Additionally, steel rebars can withstand high temperatures and fire, maintaining their strength and integrity even in the event of a fire, which is crucial for ensuring the safety of occupants. Furthermore, steel rebars are resistant to corrosion, which is a common issue in construction projects. Corrosion weakens the structure by gradually deteriorating the reinforcement. By using steel rebars, the risk of corrosion is significantly reduced, lengthening the lifespan of the construction and ensuring its long-term safety. Overall, the use of steel rebars in construction projects is vital for guaranteeing the safety and durability of structures. They enhance the strength, stability, and resistance of the building, making it capable of withstanding various external forces and potential hazards. By incorporating steel rebars into construction designs, engineers and builders can ensure that the finished project meets the required safety standards, providing peace of mind for both the construction industry professionals and the public.

Send your message to us

Deformed Steel Bar ASTM A615 GR40 GR60 with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords