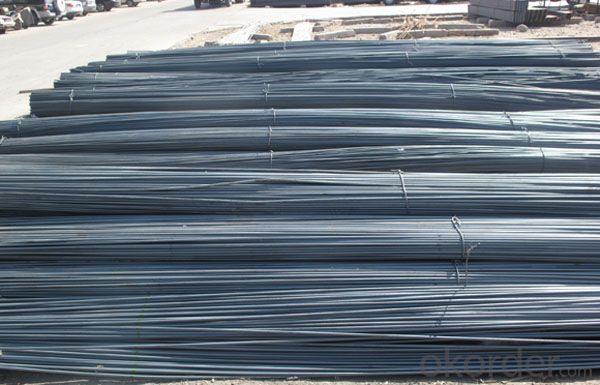

ASTM A615 deformed steel bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering ASTM A615 deformed steel bar for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

ASTM A615 deformed steel bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's deformed steel bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specificati

Hot Rolled Steel Rebar HRB 500B

1.China direct supplier

2.Best service

3.Competitive price

4.Quantity assured

Product Description

| Name | Steel,Hot Rolled Steel Structure,Deformed Steel Bar,China Manufacture H500B 12M |

| Standard | ASTM A615 /BS BS 4449 /GB HRB/ JIS G3112 |

| Grade | HRB500B |

| Diameter | 12mm-40mm |

| Length | 6-12m |

| Technique | Low temperature hot-rolling reinforcing deformed steel rebar |

| Tolerance | As the standard or as your requirement |

| Application | Building, construction, road, bridge,etc |

| Certificated | BV |

| MOQ | 500tons per size steel rebar |

| Packing details | Steel rebar packed in bundle or as your requirement |

| Delivery | Within 30 days after deposit |

| Payment | T/T or L/C |

Chemical Composition

Grade | Technical data of the original chemical composition (%) | |||||||

C | Mn | Si | S | P | V | |||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | ||

Physics capability | ||||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation (%)

| ||||||

≥400 | ≥570 | ≥14 | ||||||

Theorectical weight

Diameter (MM) | Cross Sectional Area (MM2) | Theorectical Weight (KG/M) | Weight of 12M Bar (KG) | A Ton Contains 12M Bars (PCS) |

| 6 | 28.27 | 0.222 | 2.664 | 375.38 |

| 8 | 50.27 | 0.395 | 4.74 | 210.97 |

| 10 | 78.54 | 0.617 | 7.404 | 135.06 |

| 12 | 113.1 | 0.888 | 10.656 | 93.84 |

| 14 | 153.9 | 1.21 | 14.52 | 68.87 |

| 16 | 201.1 | 1.58 | 18.96 | 52.74 |

| 18 | 254.5 | 2 | 24 | 41.67 |

| 20 | 314.2 | 2.47 | 29.64 | 33.74 |

| 22 | 380.1 | 2.98 | 35.76 | 27.96 |

| 25 | 490.9 | 3.85 | 46.2 | 21.65 |

| 28 | 615.8 | 4.83 | 57.96 | 17.25 |

| 32 | 804.2 | 6.31 | 75.72 | 13.21 |

| 36 | 1018 | 7.99 | 98.88 | 10.43 |

| 40 | 1257 | 9.87 | 118.44 | 8.44 |

FAQ:

Q1: Can stainless steel rust?

A1: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q: Are thread steels of coarse steel?

- Thread steel does not belong to coarse steel, rough is shaped steel, fine is wire.

- Q: Can steel rebars be used in residential swimming pool construction?

- Yes, steel rebars can be used in residential swimming pool construction. Steel rebars are commonly used to reinforce concrete structures, including swimming pools. The rebars provide added strength and durability to the concrete, making it capable of withstanding the pressure and weight of the water. The use of steel rebars helps prevent cracking and structural damage to the pool over time. Moreover, steel rebars are readily available, cost-effective, and can be easily installed by professional pool builders. Overall, the inclusion of steel rebars in residential swimming pool construction is highly recommended to ensure a long-lasting and reliable pool structure.

- Q: Can steel rebars be used in underground construction projects?

- Yes, steel rebars can be used in underground construction projects. Rebars are commonly used in all types of construction projects, including underground structures. The main purpose of steel rebars is to reinforce concrete and provide additional strength and stability to the structure. In underground construction, rebars are often used in the construction of foundations, walls, and columns to strengthen the concrete and ensure the integrity of the structure. The use of steel rebars in underground construction projects helps to increase the load-bearing capacity of the concrete, making it more resistant to the pressure and forces exerted by the surrounding soil and groundwater. Additionally, steel rebars are highly durable and resistant to corrosion, which makes them suitable for underground environments where they may be exposed to moisture and other potentially damaging elements. Overall, the use of steel rebars in underground construction projects is essential for ensuring the structural stability and longevity of the underground structures.

- Q: How are steel rebars tested for quality and strength?

- Steel rebars are tested for quality and strength through a series of standardized tests. These tests ensure that the rebars meet the required standards and can withstand the expected loads and stresses. One common test is the Tensile Test, which measures the maximum amount of stress a rebar can withstand before it breaks. In this test, a sample rebar is pulled until it fractures, and the force required to break it is measured. This test provides valuable information about the rebar's ultimate tensile strength, yield strength, and elongation. Another important test is the Bend Test, which evaluates the rebar's ductility and ability to withstand bending without breaking. In this test, a sample rebar is bent to a specific angle, and any cracks or fractures are closely examined. The rebar is deemed acceptable if it doesn't show any signs of failure. Additionally, Chemical Analysis is performed to determine the chemical composition of the rebar. This test ensures that the steel meets the required chemical composition standards, as different compositions can affect the rebar's strength and durability. Furthermore, the Dimensional Test checks the dimensions, weight, and shape of the rebar to ensure they comply with the specified standards. Any deviations from the required measurements can compromise the rebar's structural integrity. Moreover, the rebar's Surface Condition is examined visually to assess any signs of rust, cracks, or other defects that may affect its performance. Proper surface condition is crucial as it ensures good bonding with the surrounding concrete. Finally, some rebars undergo Non-Destructive Testing such as ultrasonic testing or magnetic particle inspection to detect any hidden defects or cracks that may not be visible to the naked eye. Overall, these testing methods are employed to ensure that steel rebars have the required quality and strength to be used in construction projects, providing the necessary reinforcement for reinforced concrete structures.

- Q: How are steel rebars used in construction?

- Steel rebars are used in construction to reinforce concrete structures and provide them with increased strength and durability. They are embedded within the concrete to withstand tension forces and prevent cracking or collapsing, ensuring the structural integrity of buildings, bridges, and other infrastructure projects.

- Q: What is the typical weight of a steel rebar?

- The typical weight of a steel rebar can vary depending on its diameter and length. However, the most commonly used steel rebar in construction projects is typically 20 feet long and ranges in diameter from 1/2 inch to 1 inch. For this standard size, the weight can range from around 7.5 pounds to 24 pounds per linear foot. Therefore, a 20-foot steel rebar can weigh anywhere between approximately 150 pounds to 480 pounds. It is important to note that different countries may have different weight standards for steel rebars, so it is always advisable to consult local specifications and standards for accurate information.

- Q: How do steel rebars affect the fire resistance of a structure?

- Steel rebars can have both positive and negative effects on the fire resistance of a structure. On one hand, steel rebars can enhance the fire resistance of a structure by providing additional strength and stability. The presence of steel rebars in concrete structures can help prevent collapse during a fire, allowing more time for occupants to evacuate and emergency responders to control the situation. However, steel rebars also have some drawbacks when it comes to fire resistance. Steel is a highly conductive material, meaning it can transfer heat quickly. During a fire, the steel rebars can heat up and transfer the heat to the surrounding concrete, potentially weakening its structural integrity. This can result in a reduced fire resistance of the structure. To mitigate the negative effects of steel rebars on fire resistance, certain measures can be taken. One common approach is to apply fire-resistant coatings or wraps to the steel rebars. These coatings or wraps act as a barrier, slowing down the heat transfer from the steel to the concrete, thus enhancing the fire resistance. Additionally, the size, spacing, and arrangement of steel rebars can also impact the fire resistance of a structure. Proper design and placement of rebars can ensure that the heat is distributed more evenly, reducing the risk of localized weakening and structural failure. In summary, steel rebars can have a significant impact on the fire resistance of a structure. While they can enhance the overall strength and stability, they can also contribute to the heat transfer and potential weakening of the structure. By implementing appropriate measures such as fire-resistant coatings and proper design, the negative effects of steel rebars on fire resistance can be minimized, ensuring the safety and integrity of the structure during a fire.

- Q: How are steel rebars transported to the construction site?

- Steel rebars are typically transported to the construction site using flatbed trucks or trailers. These vehicles are specifically designed to carry heavy loads and have the necessary infrastructure to secure and transport the rebars safely.

- Q: What is the difference between drawing steel and round steel on drawing?

- When drawing steel, it should be used to correct the name: ribbed steel bar, whose name is abbreviated as "HRB" in English. At the same time, according to the characteristic value of yield strength, it can be divided into three grades: HRB335, HRB400 and HRB500, and should be marked when marked.Bar diameter and material should be marked on the drawing, such as material of 35 / Cr12.

- Q: How do steel rebars improve the structural integrity of concrete?

- The structural integrity of concrete is greatly improved by steel rebars in several ways. Firstly, they bolster the tensile strength of concrete, which is otherwise feeble in tension. While concrete excels in compressive strength, it lacks the ability to withstand pulling or stretching forces. By inserting steel rebars into the concrete, the overall tensile strength of the structure is significantly heightened. The steel rebars function as reinforcement by dispersing stress and load across a wider area, preventing cracks and fractures from spreading through the concrete. They establish a sturdy bond between the concrete and the reinforcement, enabling the structure to bear heavy loads and withstand bending, shearing, and other forces that could jeopardize its stability. Furthermore, steel rebars aid in managing and mitigating the impacts of shrinkage and thermal expansion and contraction that occur in concrete. These occurrences frequently lead to cracking and structural damage. The steel rebars help restrict the movement of the concrete, lessening the likelihood of crack formation and ensuring the overall integrity of the structure. Moreover, steel rebars prolong the durability and lifespan of concrete structures. They possess a high resistance to corrosion, which is particularly crucial in environments with elevated moisture levels, chemical exposure, or contact with saltwater. The presence of steel rebars safeguards the concrete from deterioration and extends the lifespan of the structure. In conclusion, steel rebars play a vital role in enhancing the structural integrity of concrete by fortifying its tensile strength, distributing stress and loads, preventing cracks, managing shrinkage, resisting bending and shearing forces, and increasing durability. They provide a dependable and efficient reinforcement system that guarantees the stability and longevity of concrete structures.

Send your message to us

ASTM A615 deformed steel bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords