All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are steel rebars employed in the construction of shopping malls and commercial complexes?

Steel rebars are used in the construction of shopping malls and commercial complexes to reinforce concrete structures. They are placed strategically within the concrete to provide strength and durability to the overall building. This reinforcement ensures that the structure can withstand heavy loads, such as the weight of multiple floors, and resist forces like earthquakes or strong winds. Steel rebars also help prevent cracking and improve the overall stability of the building, making them an essential component in the construction process.

What measures are taken to prevent damage to steel rebars during the concrete pouring and compaction process in industrial facilities?

To prevent damage to steel rebars during the concrete pouring and compaction process in industrial facilities, several measures are commonly taken. Firstly, rebars are properly cleaned and coated with anti-corrosion materials before installation. This helps protect them from potential damage caused by exposure to moisture and chemicals in concrete. Secondly, rebars are securely positioned and supported using tie wire or rebar chairs to maintain their intended placement and prevent displacement during the pouring and compaction process. Additionally, plastic or metal caps are often used to cover the exposed ends of rebars, safeguarding them from any concrete splatter or debris. These measures collectively ensure the integrity and longevity of steel rebars in industrial construction projects.

What is the role of cranked bars in the design of complex steel rebar connections?

Cranked bars play a crucial role in the design of complex steel rebar connections by providing the necessary reinforcement and structural integrity. The cranked bars allow for the transfer of loads and forces between different steel elements, ensuring the stability and overall strength of the connection. They help to distribute stress and prevent the occurrence of potential failure points, enhancing the durability and performance of the structure. Additionally, cranked bars aid in accommodating variations in alignment and positioning, facilitating the efficient assembly and installation of complex steel rebar connections.

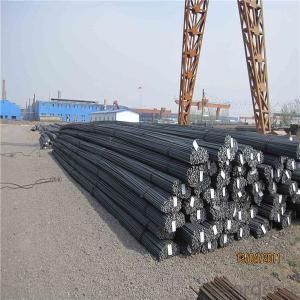

Wholesale Steel Rebars from supplier in Pakistan

With our strong supply chain network and strategic partnerships, we can offer competitive prices without compromising on quality. Our Steel Rebars are sourced from reputable manufacturers and undergo strict quality control measures to ensure durability and strength.

We understand the importance of timely delivery in construction projects, and our efficient logistics team ensures that your orders are delivered on time, every time. We also provide comprehensive after-sales support, addressing any issues or concerns you may have.

Furthermore, we also offer value-added services such as cutting, bending, and customization of Steel Rebars to meet your project's specific requirements. Our team of skilled technicians and engineers are well-equipped to handle any customization needs, ensuring that the Steel Rebars are ready for immediate use upon delivery.

At our company, we prioritize customer satisfaction and strive to build long-term relationships with our clients. We believe in open communication and transparency, and our team is always available to address any queries or provide technical support.

Choose us for all your Steel Rebars procurement needs in Pakistan and experience a hassle-free and reliable service. Contact us today for a quote or to discuss your project requirements.

We understand the importance of timely delivery in construction projects, and our efficient logistics team ensures that your orders are delivered on time, every time. We also provide comprehensive after-sales support, addressing any issues or concerns you may have.

Furthermore, we also offer value-added services such as cutting, bending, and customization of Steel Rebars to meet your project's specific requirements. Our team of skilled technicians and engineers are well-equipped to handle any customization needs, ensuring that the Steel Rebars are ready for immediate use upon delivery.

At our company, we prioritize customer satisfaction and strive to build long-term relationships with our clients. We believe in open communication and transparency, and our team is always available to address any queries or provide technical support.

Choose us for all your Steel Rebars procurement needs in Pakistan and experience a hassle-free and reliable service. Contact us today for a quote or to discuss your project requirements.