All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

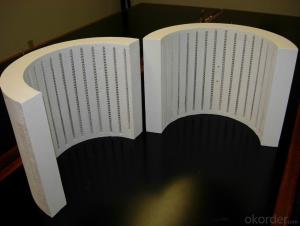

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

What are the common refractory materials used for lining kiln cars?

The common refractory materials used for lining kiln cars are high alumina bricks, silicon carbide bricks, and fireclay bricks.

What is the composition of refractory materials?

Refractory materials are typically composed of a combination of oxides, such as alumina (Al2O3), magnesia (MgO), silica (SiO2), and chromite (FeCr2O4), along with other additives to enhance their properties and performance at high temperatures.

How are refractory powders used in applications?

Refractory powders are used in applications as a key component in the production of refractory materials, which are heat-resistant materials designed to withstand high temperatures. These powders are mixed with binders and additives to create a paste that can be shaped and formed into various refractory products such as bricks, castables, and coatings. These materials are then used in industries like steel, cement, glass, and ceramics, where they serve as linings or insulation in furnaces, kilns, and other high-temperature equipment. Refractory powders provide excellent thermal resistance, chemical inertness, and mechanical strength, making them crucial for maintaining the integrity and efficiency of industrial processes operating at extreme temperatures.

What are the challenges faced by refractory materials in the construction industry?

One of the main challenges faced by refractory materials in the construction industry is their ability to withstand extremely high temperatures. These materials are often used in applications such as furnaces, kilns, and reactors, where they are exposed to intense heat. Maintaining their structural integrity and preventing them from cracking or deteriorating under these conditions is a significant challenge. Additionally, refractory materials also need to resist chemical corrosion and erosion caused by molten metals, slag, and other aggressive substances. Finding materials that can meet these requirements and provide long-term durability is crucial for the construction industry.

Wholesale Refractory Materials from supplier in Pakistan

Whether you are in the steel, cement, glass, or other industries, our refractory materials are designed to withstand high temperatures and harsh operating conditions. We understand the importance of quality and reliability in these demanding sectors, which is why we only source our products from reputable manufacturers.

Our product range includes firebricks, castables, ceramic fiber products, refractory mortars, and more. We can provide you with customized solutions tailored to your specific application and budget. Our team of technical experts is available to assist you in selecting the right materials and designing optimal refractory linings for your equipment.

In addition to our wide range of products, we also offer value-added services such as sales support, quotation assistance, and technical guidance. We understand that every project is unique, and we are committed to providing you with the best possible solution.

As part of CNBM, we have access to a global network of suppliers and resources. This enables us to offer competitive prices and ensure timely delivery of your refractory materials. Our strong presence in Pakistan and deep understanding of the local market allow us to provide you with valuable insights and expertise.

Whether you are looking for a reliable supplier for ongoing projects or need assistance with a new venture, we are here to support you every step of the way. Contact us today to discuss your refractory materials requirements in Pakistan.

Our product range includes firebricks, castables, ceramic fiber products, refractory mortars, and more. We can provide you with customized solutions tailored to your specific application and budget. Our team of technical experts is available to assist you in selecting the right materials and designing optimal refractory linings for your equipment.

In addition to our wide range of products, we also offer value-added services such as sales support, quotation assistance, and technical guidance. We understand that every project is unique, and we are committed to providing you with the best possible solution.

As part of CNBM, we have access to a global network of suppliers and resources. This enables us to offer competitive prices and ensure timely delivery of your refractory materials. Our strong presence in Pakistan and deep understanding of the local market allow us to provide you with valuable insights and expertise.

Whether you are looking for a reliable supplier for ongoing projects or need assistance with a new venture, we are here to support you every step of the way. Contact us today to discuss your refractory materials requirements in Pakistan.

Hot Search

- Monolithic Refractories in Lesotho

- Ceramic Fiber Products in Cameroon

- Refractory Bricks in Chile

- Raw Materials For Refractory in Liechtenstein

- Monolithic Refractories in Belarus

- Raw Materials For Refractory in Kiribati

- Ceramic Fiber Products in Samoa

- Refractory Bricks in Cuba

- Monolithic Refractories in Tonga

- Refractory Bricks in Japan