Steel Rebar KS Standard SD400

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

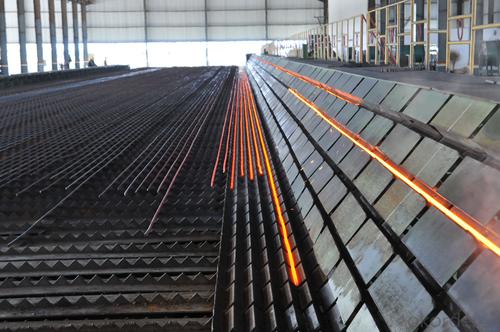

OKorder is offering Steel Rebar KS Standard SD400 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Rebar KS Standard SD400 are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Rebar KS Standard SD400 are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: SD400,SD500

Size: 6mm-32mm

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

| DEFORMED BAR | |

| SIZE d(mm) | theoretical kg/m |

| 6 | 0.222 |

| 8 | 0.395 |

| 10 | 0.617 |

| 12 | 0.888 |

| 14 | 1.21 |

| 16 | 1.58 |

| 18 | 2 |

| 20 | 2.47 |

| 22 | 2.98 |

| 25 | 3.85 |

| 28 | 4.83 |

| 32 | 6.31 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How soon can we receive the product after purchase?

A2: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Q3: what is the difference between actual weight and theoretical weight?

A3: All the section steel has two weights: actual weight and theoretical weight. Actual weight is the weighing out when the product delivered from the mill. Theoretical weight is calculated by pieces. The invoice can be based on each of them as your request.

Images:

- Q: What are the factors that can cause steel rebars to corrode prematurely?

- There are several factors that can contribute to the premature corrosion of steel rebars. These include exposure to moisture, high levels of chloride ions, carbonation of concrete, inadequate concrete cover, poor quality of concrete or protective coatings, and the presence of other aggressive chemicals such as sulfates or acids. Environmental conditions, such as high humidity, coastal areas, or industrial environments, can also accelerate the corrosion process. Additionally, improper construction practices, such as inadequate compaction or curing of concrete, can lead to the initiation and progression of corrosion in steel rebars.

- Q: Can steel rebars be used in tunnel boring machine (TBM) construction?

- Steel rebars are indeed utilized in the construction of tunnel boring machines (TBMs). In the construction sector, rebars are a commonly employed means of reinforcing concrete structures, including tunnels built with TBMs. The objective of incorporating rebars is to furnish the concrete lining of the tunnel with added strength and durability. These rebars are typically inserted into the concrete lining during the construction process, augmenting its structural integrity and capacity to withstand external forces. In TBM construction, the rebars are meticulously positioned and secured to ensure proper reinforcement throughout the tunnel. Consequently, steel rebars assume a pivotal role in the construction of tunnels utilizing TBMs.

- Q: Are steel rebars prone to rusting?

- Steel rebars have a tendency to rust. Rebars are composed mainly of carbon steel, which contains iron. When exposed to moisture and oxygen, the iron in steel rebars undergoes a chemical reaction known as oxidation, resulting in the formation of rust or iron oxide. This process can be accelerated in environments with high humidity, coastal regions with saltwater exposure, or when the rebars come into contact with water or other corrosive substances. The rusting of steel rebars can weaken their structural integrity and compromise the strength and durability of concrete structures. Therefore, it is crucial to protect rebars from rust by applying anti-corrosion coatings or using stainless steel rebars in areas prone to rusting. Regular maintenance and inspection are also important for promptly identifying and addressing any rust-related issues.

- Q: What is the effect of exposure to extreme temperatures on steel rebars?

- Exposure to extreme temperatures can have a significant effect on steel rebars. When exposed to high temperatures, steel rebars can undergo thermal expansion, causing them to expand and potentially lose their original shape. This expansion can lead to cracks, weakening the rebars' structural integrity. On the other hand, exposure to extremely low temperatures can cause the rebars to contract, which may result in stress and potential cracking. Overall, extreme temperature exposure can compromise the strength and durability of steel rebars, posing risks to the structures they support.

- Q: Are steel rebars suitable for use in structures with high resistance to chemicals?

- Steel rebars are generally not suitable for use in structures with high resistance to chemicals. While steel is a strong and durable material, it is susceptible to corrosion when exposed to certain chemicals. Chemicals such as acids, alkalis, and chlorides can cause steel rebars to corrode, which can compromise the structural integrity of the building or structure. To ensure high resistance to chemicals, alternative materials such as stainless steel rebars or fiber-reinforced polymer (FRP) rebars are often used. Stainless steel rebars are more resistant to corrosion than regular steel rebars due to their higher chromium content. FRP rebars, on the other hand, are non-metallic and do not corrode, making them a suitable choice for structures exposed to harsh chemical environments. Ultimately, the choice of rebars in structures with high resistance to chemicals depends on the specific chemicals involved and the level of exposure. It is important to consult with engineers and experts who can assess the chemical environment and recommend the most suitable rebars to ensure the long-term durability and safety of the structure.

- Q: How do steel rebars affect the overall construction timeline?

- Steel rebars can have a significant impact on the overall construction timeline. They are crucial for reinforcing concrete structures, enhancing their strength and durability. However, the installation of steel rebars requires careful planning, coordination, and precision. Delays in procuring, fabricating, or installing rebars can disrupt the construction schedule, leading to project delays. On the other hand, efficient handling of rebars can expedite construction, ensuring timely completion. Therefore, the management of steel rebars plays a vital role in determining the overall construction timeline.

- Q: How long do steel rebars typically last before corroding?

- Steel rebars typically last for several decades before they start to corrode, depending on various factors such as the quality of the steel, environmental conditions, and the presence of protective coatings.

- Q: How do steel rebars contribute to the sustainability of a building?

- There are several ways in which steel rebars contribute to the sustainability of a building. To begin with, the utilization of steel rebars in reinforced concrete structures enhances the overall strength and durability of the building, thus extending its lifespan. This, in turn, reduces the frequency of repairs or replacements, resulting in less material consumption and waste generation over time. Moreover, steel rebars are manufactured from recycled materials, with a significant proportion being derived from scrap metal. This helps to decrease the demand for new steel production, which is an energy-intensive process and contributes to carbon emissions. By making use of recycled steel rebars, buildings can significantly reduce their carbon footprint and conserve natural resources. Furthermore, steel rebars aid in improving the structural integrity of the building, making it more resistant to various external forces such as earthquakes, hurricanes, and other natural disasters. This increased resilience decreases the potential for catastrophic damage and the subsequent need for major reconstruction or demolition, thus saving both resources and costs. Additionally, the utilization of steel rebars allows for the construction of taller and more open spaces, enabling efficient use of the building's footprint. This is particularly relevant in urban areas where land availability is limited. By enabling the construction of taller buildings, steel rebars contribute to urban densification, which helps to reduce urban sprawl and preserve natural habitats. Lastly, steel rebars are highly recyclable at the end of their service life. When a building is demolished, the steel rebars can be easily extracted and recycled, avoiding the accumulation of construction waste in landfills. The recycling of steel rebars saves energy and reduces the need for extracting and processing new materials, further contributing to the sustainability of the construction industry. In conclusion, steel rebars play a crucial role in enhancing the sustainability of a building by increasing its durability, utilizing recycled materials, improving structural resilience, enabling efficient land use, and facilitating the recycling of materials at the end of a building's life cycle.

- Q: Are steel rebars suitable for use in high-traffic areas like bridges?

- Yes, steel rebars are suitable for use in high-traffic areas like bridges. Steel rebars provide exceptional strength and durability, making them ideal for withstanding heavy loads and frequent use. Additionally, steel rebars offer excellent resistance to corrosion, ensuring the longevity and structural integrity of bridges in high-traffic areas.

- Q: What are the guidelines for proper tying of steel rebars in concrete structures?

- To ensure the structural integrity and durability of concrete structures, it is crucial to adhere to guidelines for the proper tying of steel rebars. Here are some important guidelines to consider: 1. Rebar Placement: Before tying, accurately position the rebars according to the structural drawings and design specifications. Place them at the designated locations and depths, ensuring proper spacing to provide the necessary strength and reinforcement. 2. Tying Tools: Utilize suitable tools like pliers or rebar tying machines for secure and proper tying. Ensure that the tools are in good condition and appropriate for the size and type of rebars being used. 3. Tying Technique: Employ a consistent and efficient tying technique. Begin by securely holding the rebars together at the intersection point. Wrap the tie wire around both rebars multiple times, ensuring tight and firm connections. Properly twist and neatly cut the tie wire to avoid any protrusions. 4. Tie Wire Selection: Use high-quality tie wires with sufficient strength to withstand tension and load requirements. Opt for corrosion-resistant materials such as galvanized steel or stainless steel to prevent rusting and deterioration over time. 5. Tying Spacing: Adhere to the specified tying spacing as per the design requirements. Adequate spacing between ties helps maintain rebars in their designated positions, preventing displacement during concrete pouring and subsequent curing. 6. Tying Quantity: Tie rebars at suitable intervals to ensure ample connection and reinforcement. The number of ties needed depends on the size, shape, length of rebars, and structural design specifications. 7. Tying Consistency: Maintain consistency in tying throughout the entire concrete structure. Uneven or inconsistent tying can result in weak points, reduced reinforcement, and compromised structural integrity. 8. Tying Safety: Prioritize safety during the tying process. Wear appropriate personal protective equipment (PPE) like gloves and safety glasses to prevent injuries. Take precautions to avoid tripping hazards and ensure a safe working environment. 9. Inspection and Quality Control: Regularly inspect the tied rebars to ensure compliance with design specifications and quality standards. Conduct visual inspections and perform pull tests to assess the strength and effectiveness of the ties. 10. Compliance with Codes and Standards: Adhere to local building codes, industry standards, and engineering guidelines specific to your region. These codes provide essential requirements for rebar tying, ensuring the durability and safety of the concrete structure. By following these guidelines, construction professionals can enhance the strength, stability, and longevity of concrete structures through proper tying of steel rebars.

Send your message to us

Steel Rebar KS Standard SD400

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords